ER200 PERFECT WINDOW™FRESH AIR VENTILATION SYSTEM

68-0131—2

5

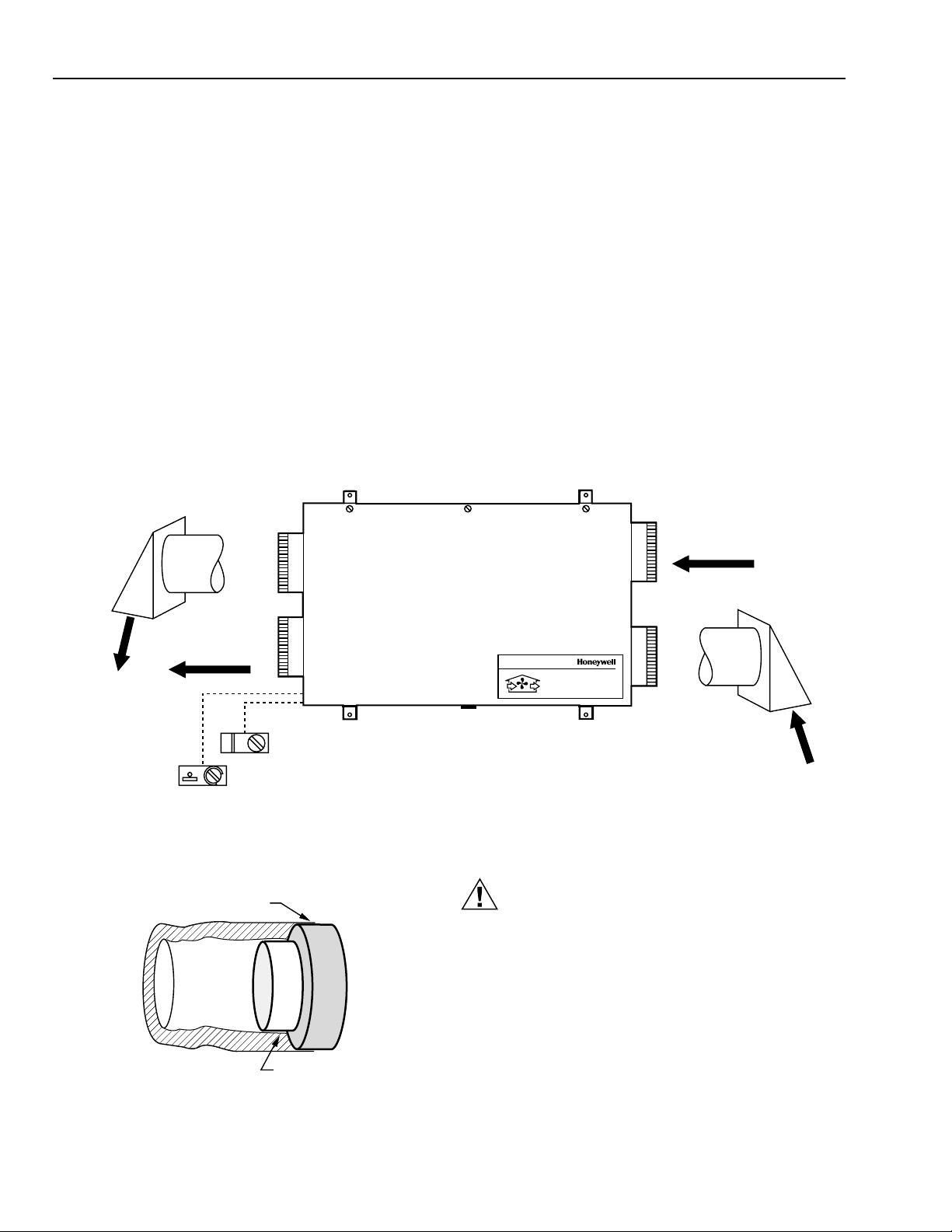

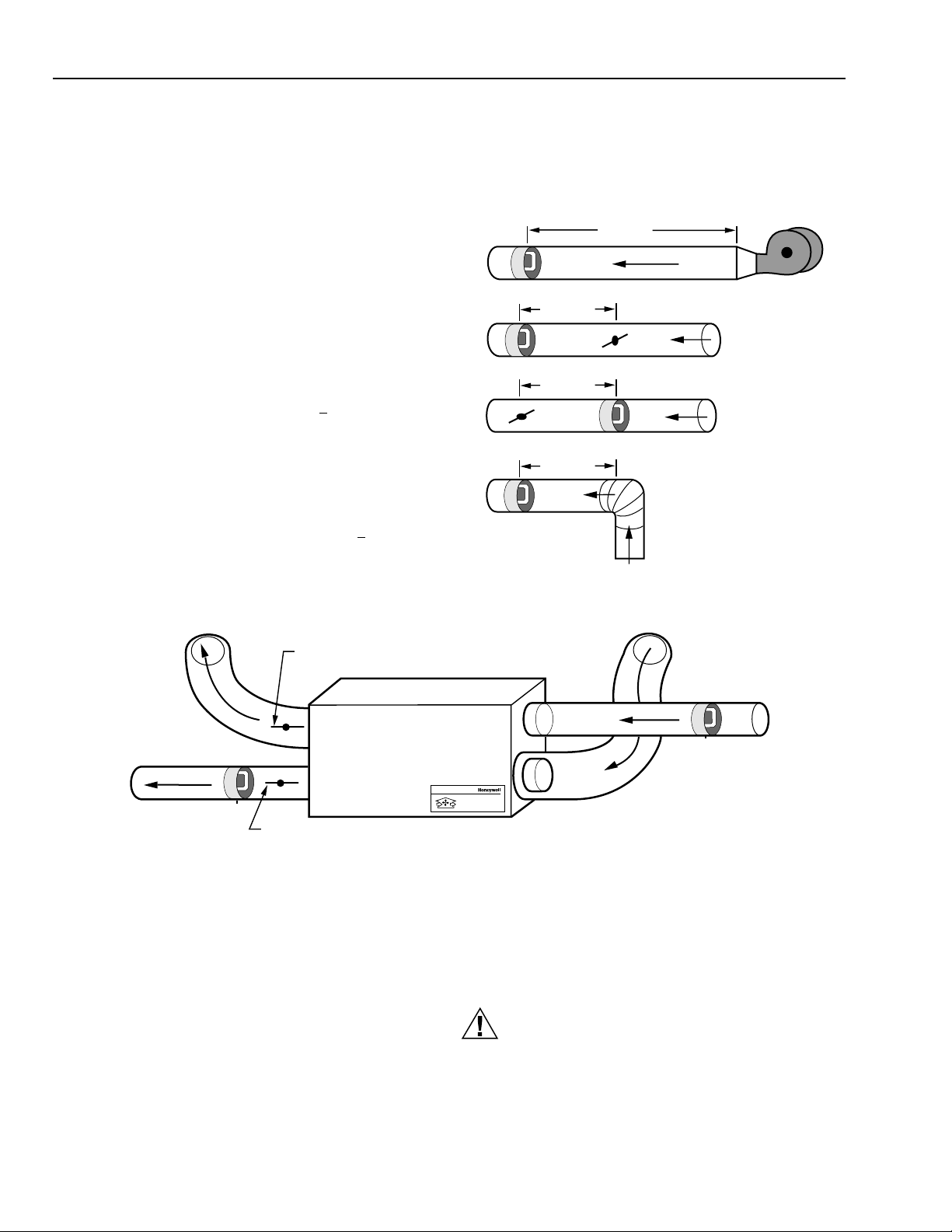

2. Use 7-in. diameter round duct for all connections to and

from the ventilator.

3. Plan fresh air supply for good ventilation efficiency.

Separate outside vents from intake and exhaust by at

least 6 ft (2m).

NOTE:

•Fresh air should not blow directly onto

occupants or thermostat.

•Do not locate the fresh air intake close to

known sources of pollutants such as

automobile exhaust, dryer vent or chimney

smoke.

4. Supply air can be ducted directly to the return side of a

forced-air heating or air conditioning system. This can

provide excellent distribution of fresh air while saving

substantially on installation.

NOTE: Continuous operation of the ER200 during

periods of occupancy is recommended. When

the furnace air handler operates, fresh air will

be distributed through the heating/air

conditioning supply registers. When the air

handler is off, fresh air will be delivered

through both supplies and returns.

5. Use electrical interlock or automatic powered damper to

prevent unwanted entry of outside air in the event that

the ER200 is turned off while the furnace air handler

continues to operate.

Balancing Airflow

Balancing the airflow is important to verify that the Fresh Air

Ventilation System is delivering the intended airflow and

energy performance. Use the Balancing Airflow instructions in

the Installation section to check and balance the airflow.

Controls

Remote Override Switch Functions—On/Off Control

If continuous ventilation is not required, an on/off control can

be used to activate the ventilator when it is switched to

Standby. Controls that can be used for this function include

dehumidistats, timers, wall switches and the ventilate function

of the Perfect Climate® Comfort Center™. If moisture control

in bathrooms is a primary function of the system, a

dehumidistat can be used to switch the ventilator from a Low

or Standby setting to the High setting. Moisture removal

throughout the entire home can be achieved only when the

outside air contains less moisture than the inside air (typically

during cold weather conditions).

With the Perfect Climate® Comfort Center™, the ventilator

can be controlled automatically by using the programmed

times or manually by pressing the VENTILATE button on the

keypad. See the Perfect Climate Comfort Center User’s Guide

(form 69-0891) for complete instructions.

Moisture Control

For optimum indoor air pollutant reduction and humidity

control, continuous operation of the ventilation system is

recommended. Increased moisture removal will always occur

at maximum ventilation rates. This high setting should be

used when first occupying a new building to remove excess

moisture from new wood, plaster, cement and other moisture

absorbing construction materials. If the system is wired to a

dehumidistat, preselected moisture levels will be maintained

automatically. For correction of severe moisture problems, the

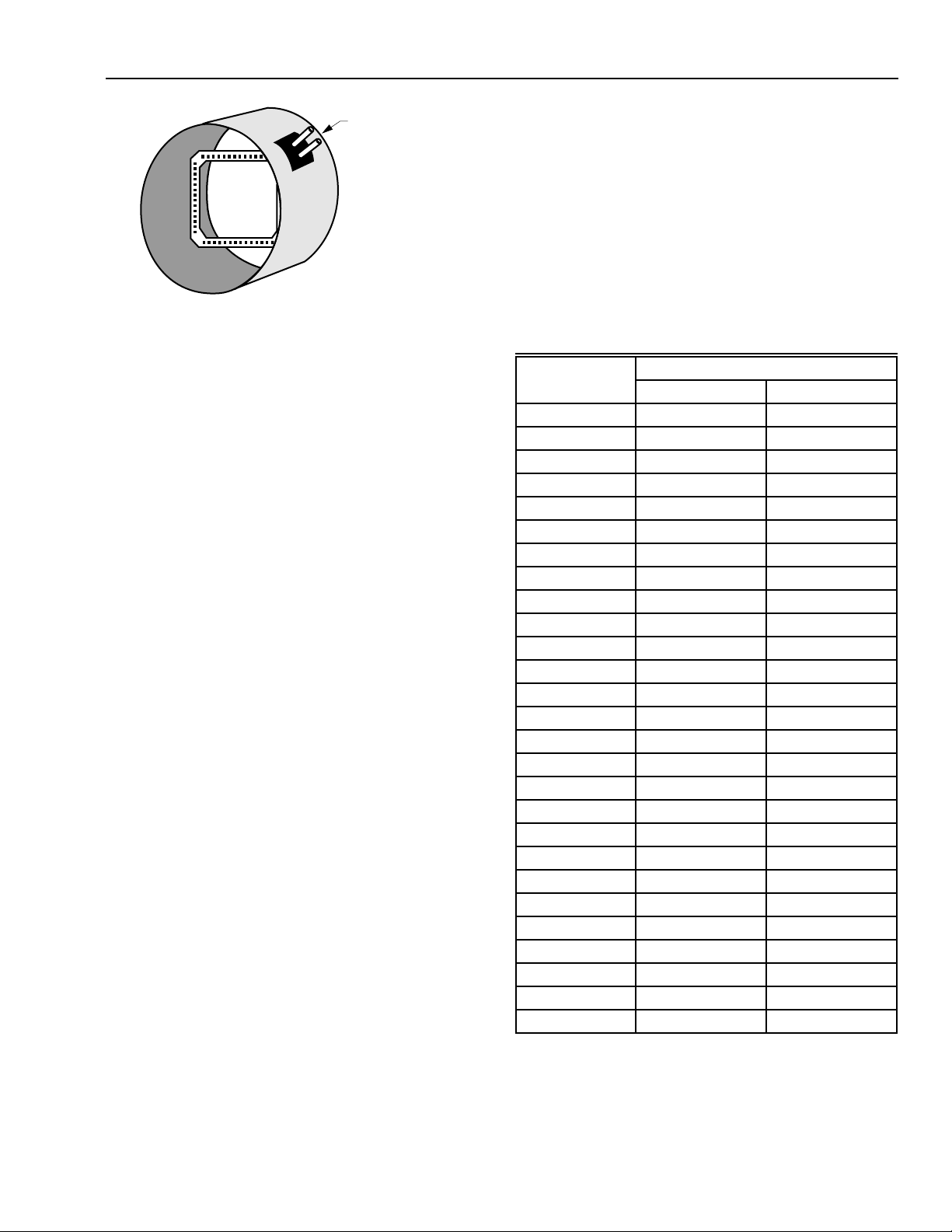

sensible energy transfer wheel can be substituted for the

desiccant coated wheel.

Frost Control

Select models have a factory installed automatic preheat frost

control system that operates to prevent the inlet air

temperature from falling below 10°F (-12°C). The frost control

system is designed to maintain this level down to outdoor

temperatures of -29°F (-34°C) with 40 percent indoor relative

humidity. The light located next to the press-to-test button

lights when the frost control preheater is active or the TEST

button is pressed.

IMPORTANT

Release the TEST button as soon as the neon light

comes on. Pressing the TEST button longer can

cause overheating of the ventilator.

INSTALLATION

When Installing this Product

1. Read these instructions carefully. Failure to follow them

could damage the ER200 or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

ER200 to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

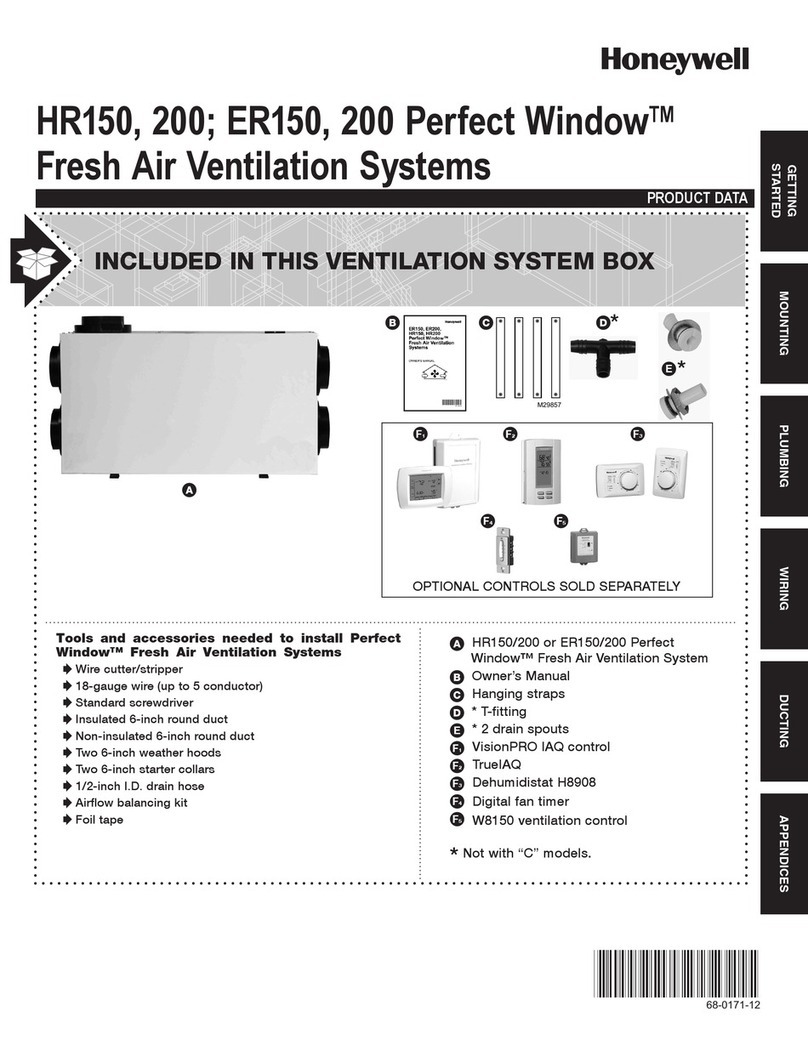

Unpack Fresh Air Ventilation System

The Fresh Air Ventilation System is shipped assembled. Check

that all the components are included. The unit consists of:

•Painted finish cabinet with starting collars.

•Variable speed fresh air control.

•Built-in preheater (on selected models).

•Two mounting straps.

•Hardware package.

•Literature package.

The Fresh Air Ventilation System comes ready for installation

as received. Wiring and ducting are required to complete the

installation. Before proceeding, check to make sure all the

components are available.

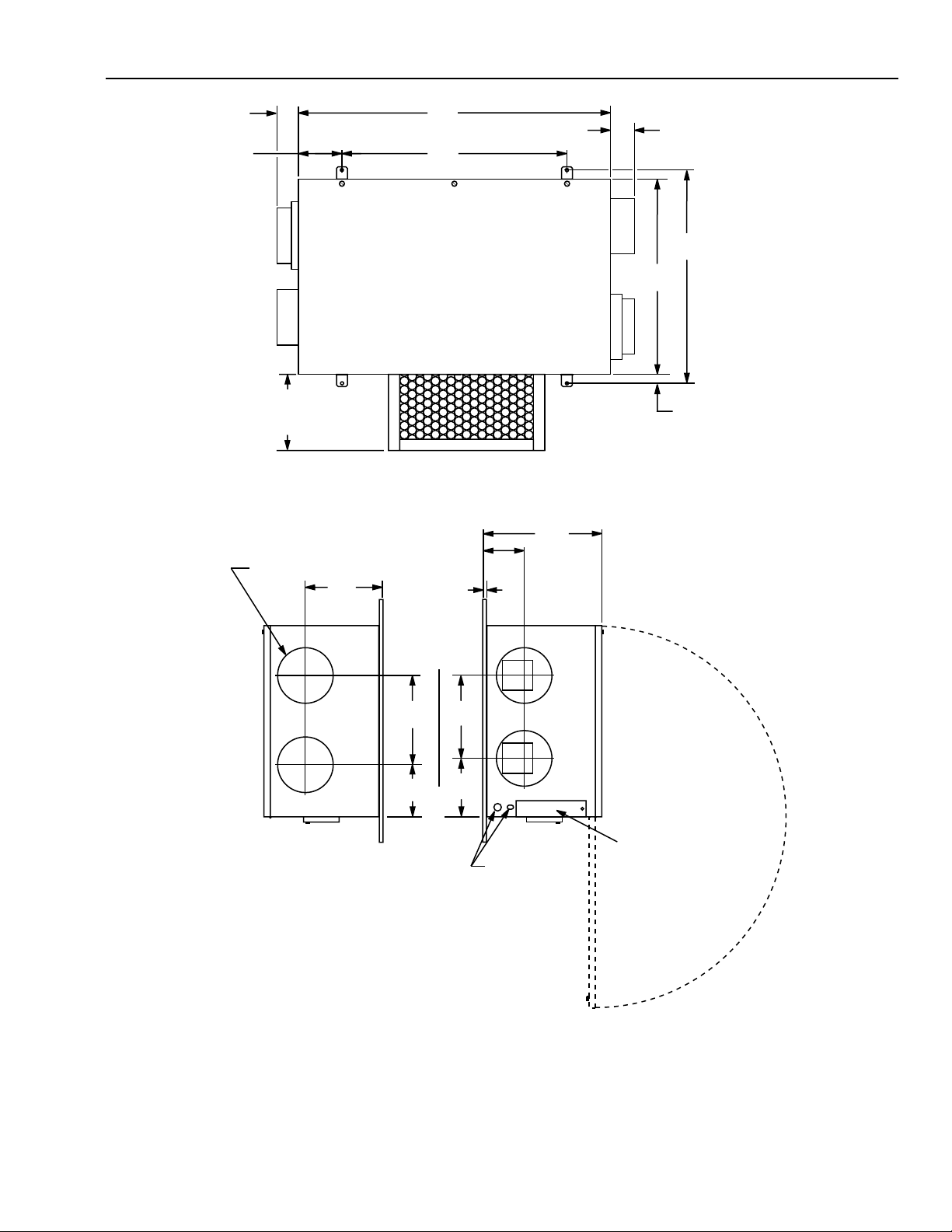

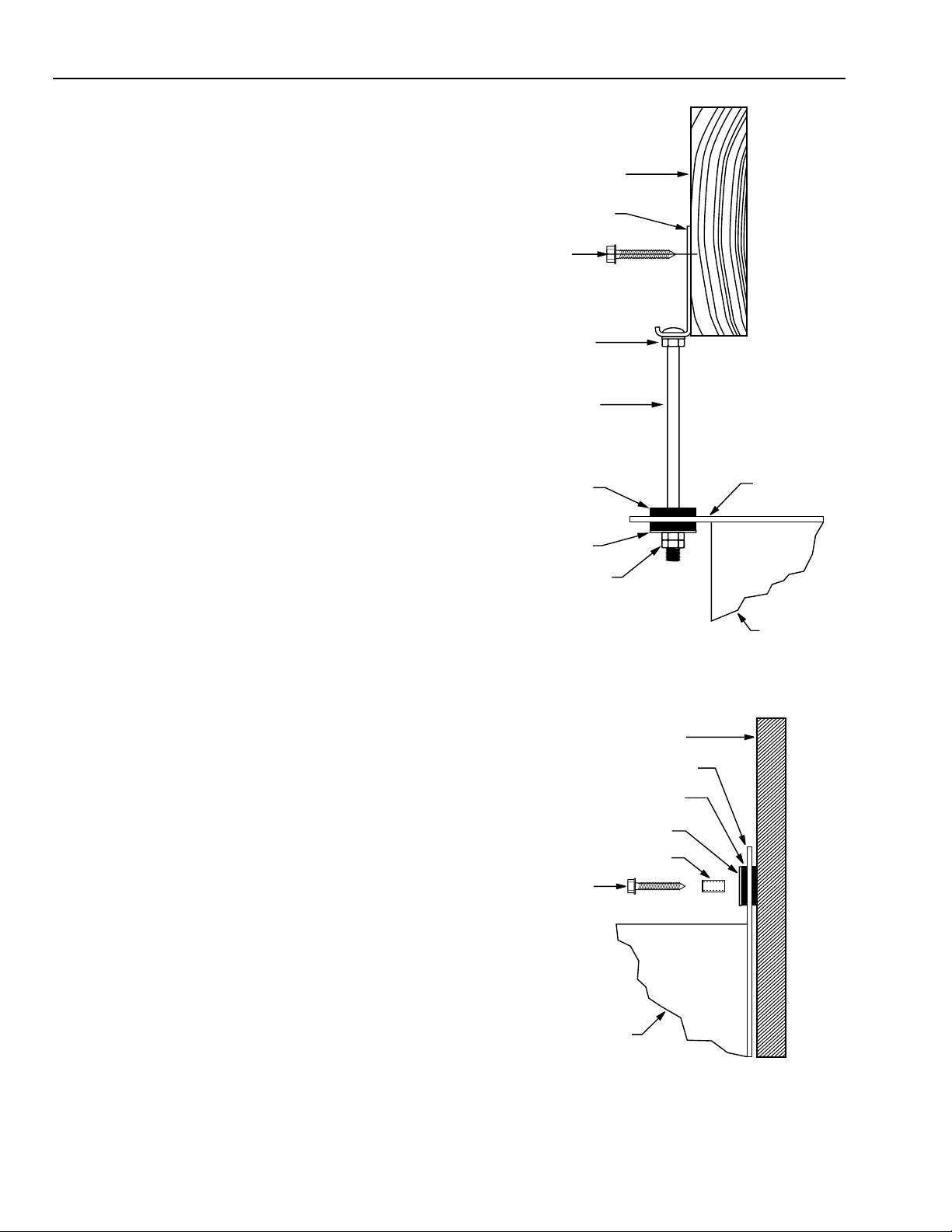

Review the Installation Plan

Place the unit on the floor; position it as it will be when

installed. Cut out the mounting template printed on the outer

carton. Use the template to determine the location of the

mounting straps. Make sure all the required duct work and

additional accessories are available before starting the

installation.