TRAMEX CME5 User manual

USER GUIDE

CONCRETE

MOISTURE ENCOUNTER

- CME5 -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

TABLE OF CONTENTS

Introduction............................................................................................2

How it works......................................................................................3-4

Instrument Features......................................................................5-7

Working With your Concrete Moisture Encounter 5.........8

• Drying time for concrete floors and screeds.............8

• Pre-test conditioning and preparation.........................9

Operating Instructions........................................................... 0- 2

Limitations........................................................................................... 3

Calibration............................................................................................ 3

Warranty................................................................................................. 4

Warranty Claims ............................................................................... 5

Product Development.................................................................... 5

Safety...................................................................................................... 6

Contact Information........................................................................ 7

2

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

INTRODUCTION

Hi there! Thank you for trusting our brand and choosing

the Concrete Moisture Encounter CME5, from Tramex. It

is our goal to ensure that you are always happy with what

you bought from us, so please let us know if you have any

questions and rest assured, we are always here to help.

The Concrete Moisture Encounter CME5 is a non-invasive

handheld electronic instrument used for accurate,

instant and non-destructive testing of Moisture Content

in concrete and cementitious slabs and screeds, giving

Carbide Method equivalent readings for both concrete

and Anhydrite. It has been designed for the Flooring, Water

Damage Restoration, Inspection/Surveying and Indoor

Air Quality industries. To get the maximum benefit from

the Concrete Moisture Encounter CME5, it is suggested

that you read this manual to familiarize yourself with the

instrument and its capabilities, before undertaking any

flooring tests.

Why should a test be done?

Concrete floor slabs and screeds that are insufficiently

dry before flooring is posed, and high moisture content in

existing floor substrates can cause a host of costly

flooring system failures. Testing allows for confidence

in a job well done that meets manufacturer’s

recommendations, official standards and customer

satisfaction.

When should a test be done ?

Concrete floor slabs and screeds should be tested

regularly during the drying period, to help evaluate and

control the drying process, and ensure that the substrate

has reached sufficient dryness before the floor covering is

installed. For the purpose of restoration, testing can

3

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

be done on existing concrete, floors and screeds to

evaluate the extent and source of water damage, as well

as controlling the drying process

HOW IT WORKS

The Concrete Moisture Encounter CME5 detects and

evaluates the moisture conditions within the cementi-

tious slab or screed by non-destructively measuring the

electrical impedance, which varies in proportion to the

moisture content in the material under test. The

electrical impedance is measured by creating a low

frequency alternating electric field between the

electrodes on the base of the meter as illustrated in the

diagram below.

4

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

This field penetrates the material under test. A very

small alternating current flows through the field. The

Concrete Moisture Encounter CME5 detects this

current, determines its amplitude and converts it to a

moisture content value. By simply pressing the Concrete

Moisture Encounter CME5 down on the surface in stra-

tegically chosen locations, instant readings can be taken

over a large area in the shortest possible time.

Instrument pressed on to material surface to measure/detect moisture

Material sample

Alternating Electric Field

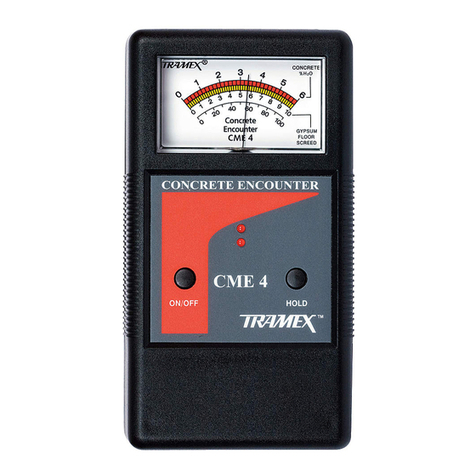

INSTRUMENT FEATURES

The instrument face with brief notes on the push button

controls and LED indicators is shown below.

85mm

= Moving coil meter.

2 = Bluetooth ON LED

3 = Hold flashing LED.

4 = Bluetooth button

5 = Hold button.

6 = Power ON LED.

7 = Power ON/OFF button.

85mm

= Moving coil meter.

5

3

6

2

60mm

47

5

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

INSTRUMENT FEATURES

Your Concrete Moisture Encounter CME5 employs

advanced analog and digital technology to enable the

incorporation of the many features listed below.

• Three simple push controls - On/Off; Hold;

Bluetooth; with corresponding LED indicators.

• The Concrete Moisture Encounter CME5 has three

scales:

Top Scale - Red - Concrete Moisture Content

(MC%) readings for Concrete Slabs & Sand/Ce-

ment screeds, 0 - 6 % moisture by mass/weight as

per the oven dry/gravimetric method.

Middle Scale - Blue - for use with Anhydrite, Hemi-

hydrate or Calcium Sulphate Screeds. These are

equivalent readings to the Carbide Method (CM)

test for Anhydrite.

Bottom Scale - Yellow - for use with Concrete slabs

or Sand/Cement screeds. These are equivalent

readings to the Carbide Method (CM) test for

Concrete.

• To conserve battery life, the instrument automati-

cally powers OFF after 5 minutes of inactivity.

• Power remains on if a change in meter reading is

detected or any button is pressed.

6

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

• The 3 LED indicators:

The ON LED illuminates when the ON/OFF button

is pressed and remains on until the Concrete Mois-

ture Encounter CME5 automatically powers off.

The Hold LED flashes when HOLD is selected.

If the batteries are nearing end of life, all LEDs

flash sequentially for 3 seconds at each power ON

to indicate that the batteries should be replaced.

• HOLD button freezes needle on moving coil meter,

to facilitate ease of recording readings.

• If HOLD was selected prior to the Concrete Mois-

ture Encounter CME5 automatically powering off,

the frozen meter reading is digitally memorized

and restored next time ON/OFF is selected.

• If Bluetooth was selected prior to the Concrete

Moisture Encounter CME5 automatically power-

ing off it will be restored next time ON/OFF is

selected.

7

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

8

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

WORKING WITH THE CONCRETE MOISTURE

ENCOUNTER 5

Drying time for concrete floors and screeds

Concrete floors and screeds must be allowed to dry

to an adequate level before the installation of floor

coverings or application of coatings. Manufacturers of

such systems generally require moisture testing to be

performed before installation or use on a floor slab.

Excessive moisture in a floor slab after the installation

of a floor covering or coating can cause failures such as

condensation, blistering, delaminating, movement and

general deterioration of the finished flooring/coating.

There is also a risk of promoting microbial growth.

No exact period can be specified for the drying of such

floors as this is affected by temperature and humidity

within the building as well as concrete curing times and

other factors. Typically a period of at least 3 to 4 weeks

per 25mm ( inch) depth of concrete or sand/cement

screed needs to be allowed. Longer periods may be

required in areas of high humidity or low temperature.

During the drying period and prior to applying the

floor covering, the floor should be regularly checked to

monitor moisture content with the Concrete Moisture

Encounter CME5.

9

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

Pre-test conditioning and preparation

For best and most accurate results, to allow for an

accurate reflection of the amount of moisture present

and moisture movement in the slab during normal

operating conditions:

• Artificial heating or drying equipment should be

turned off at least 96 hours before final readings

are taken.

• Internal conditions of the building should have

been at normal service temperature and humidity

for at least 48 hours.

Prior to testing, the surface should be prepared:

• The test area should be clean and free of any

foreign substances.

• All covering materials, adhesive residue, cur-

ing compound, sealers, paints, etc., should be

removed to expose a test area of clean bare

concrete, strictly observing all the appropriate

safety and health practices.

• Removal of covering materials and cleaning if

required should take place a minimum of 48 hours

prior to testing.

• Use of water based cleaning methods that could

lead to elevated surface and/or sub-surface mois-

ture levels in the floor slab are not recommended.

0

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

Operating Instructions

. Power on by pressing ON/OFF button. The power

LED will light up and remain on.

NOTE

If the battery voltage is getting low, the LEDs will

flash sequentially for a short period. The instru-

ment will continue to operate for some time but it

is recommended that the batteries be replaced as

soon as convenient.

2. The Concrete Moisture Encounter CME5 features

Bluetooth wireless connectivity. If you would like

to use an APP to record readings and information,

please ensure that the Bluetooth is turned on and

the LED indicator illuminated. Your Concrete Mois-

ture Encounter CME5 identifier will be the serial

number that is found on the back of the meter.

3. Press the Concrete Moisture Encounter CME5

directly onto the surface of the material being

tested, having removed any dust or foreign matter

from both the Concrete Moisture Encounter CME5

electrodes and the floor slab. Ensure that all of the

electrode spring-loaded pins are fully compressed.

4. Reading the Concrete Moisture Encounter CME5

analog dial:

• Top Scale - Red - Concrete Moisture Content (MC%)

readings for Concrete Slabs & Sand/Cement

screeds, 0 - 6 % moisture by mass/weight as per the

oven dry/gravimetric method.

• Middle Scale - Blue - for use with Anhydrite, Hemi-

hydrate or Calcium Sulphate Screeds. These are

equivalent readings to the Carbide Method (CM) test

for Anhydrite.

• Bottom Scale - Yellow - for use with Concrete slabs

or Sand/Cement screeds. These are equivalent read-

ings to the Carbide Method (CM) test for Concrete.

5. The HOLD function is especially useful when taking

readings in areas where it is difficult to see the

analog dial while it is being pressed onto the surface.

• Press the HOLD button once for easy and accurate

readings. The needle freezes on the analog dial. The

HOLD LED light flashes slowly indicating HOLD is on.

• If the Concrete Moisture Encounter CME5 is

powered off while on HOLD, the frozen reading is

digitally memorized and restored when powered on

again.

• Press the Hold button again to remove the frozen

reading in order to take further readings.

6. Recommendations.

• Take a number of tests (3-4) in close proximity to

each other, as the distribution of moisture

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

7. Power down by pressing ON/OFF. The power

LED light will go off.

tends to become erratic as concrete dries out. Use

only the highest reading.

• Avoid testing in locations subject to direct sunlight or

sources of heat.

• Include tests in potentially damp areas such as the

center of the slab and within 3 feet ( meter) of the

walls.

• Always refer to the adhesive and/or floor covering

manufacturer’s recommendations for the acceptable

moisture content levels of concrete or floor screeds.

NOTE

To conserve battery life, the Concrete Moisture

Encounter CME5 automatically powers OFF after 5

minutes of inactivity.

NOTE

The Concrete Moisture Encounter CME5 is calibrated

to give percentage moisture content readings on a

clean, bare dust free concrete floor slab, therefore

readings taken on concrete slabs through paint, coat-

ing, adhesives or other materials on the surface of the

slab should be regarded as qualitative or comparative

and not quantitative.

2

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

3

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

LIMITATIONS

The Concrete Moisture Encounter CME5 will not detect

or measure moisture through any electrically conductive

materials including metal sheeting or cladding, many

types of black EPDM rubber or wet surfaces. The Con-

crete Moisture Encounter CME5 is not suited for taking

comparative readings in the concrete substrate through

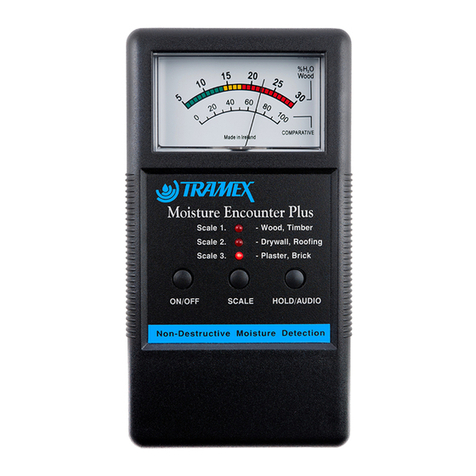

thick floor coverings such as wood. The Tramex Moisture

Encounter is more suitable for this purpose. Moisture

readings taken with the Concrete Moisture Encounter

CME5 indicate the conditions at the time of testing.

CALIBRATION

For regular on-site assessment of your Concrete Mois-

ture Encounter CME5 in moisture measurement mode,

a calibration-check plate is available from the suppliers

of your Concrete Moisture Encounter CME5. Should it

be found that readings are outside the set tolerances, it

is recommended that the Concrete Moisture Encounter

CME5 be returned for re-calibration. Click here for a

Calibration Request. Calibration adjustments should

not be carried out by anyone other than Tramex or their

authorized service provider who will issue a calibration

certificate on completion. Requirements for quality man-

agement and validation procedures, such as ISO 900 ,

have increased the need for regulation and verification of

measuring and test instruments.

It is therefore recommended that calibration of the

Concrete Moisture Encounter CME5 should be checked

and certified in accordance with the standards and/

or protocols laid down by your industry (usually on an

annual basis) by an authorized test provider. The name

of your nearest test provider and estimate of cost is

available on request.

WARRANTY

Tramex warrants that this instrument will be free from

defects and faulty workmanship for a period of one year

from date of first purchase. If a fault develops during the

warranty period, Tramex will, at its absolute discretion,

either repair the defective product without charge for

the parts and labor, or will provide a replacement in

exchange for the defective product returned to Tramex

Ltd. This warranty shall not apply to any defect, failure

or damage caused by improper use or improper or inad-

equate maintenance and care.

In no event shall Tramex, its agents or distributors be

liable to the customer or any other person, company or

organisation for any special, indirect, or consequential

loss or damage of any type whatsoever (including, with-

out limitation, loss of business, revenue, profits, data,

savings or goodwill), whether occasioned by the act,

breach, omission, default, or negligence of Tramex Ltd.,

whether or not foreseeable, arising howsoever out

4

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

5

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

of or in connection with the sale of this product

including arising out of breach of contract, tort, mis-

representation or arising from statute or indemnity.

Without prejudice to the above, all other warranties,

representations and conditions whether made orally

or implied by circumstances, custom, contract, equity,

statute or common law are hereby excluded, including

all terms implied by Section 3, 4 and 5 of the Sale

of Goods Act 893 and Sale of Goods and Supply of

Services Act 980.

WARRANTY CLAIMS

A defective product should be returned shipping pre

paid, with full description of defect to your supplier or

to Tramex Ltd.

PRODUCT DEVELOPMENT

It is the policy of Tramex to continually improve and

update all its products. We therefore reserve the right

to alter the specification or design of this instrument

without prior notice.

6

- Back to Top -

CONCRETE MOISTURE ENCOUNTER 5 USER GUIDE

SAFETY

This Users Guide does not purport to address the safety

concerns, if any, associated with this instrument or its

use. It is the responsibility of the user of this instrument

to establish appropriate safety and health practices and

determine the applicability of regulatory limitations

prior to use.

Other manuals for CME5

4

Table of contents

Other TRAMEX Measuring Instrument manuals

TRAMEX

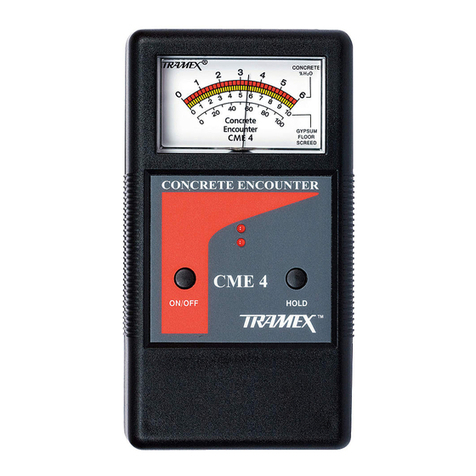

TRAMEX CME 4 User manual

TRAMEX

TRAMEX CME 4 User manual

TRAMEX

TRAMEX ME5 User manual

TRAMEX

TRAMEX MEX5 User manual

TRAMEX

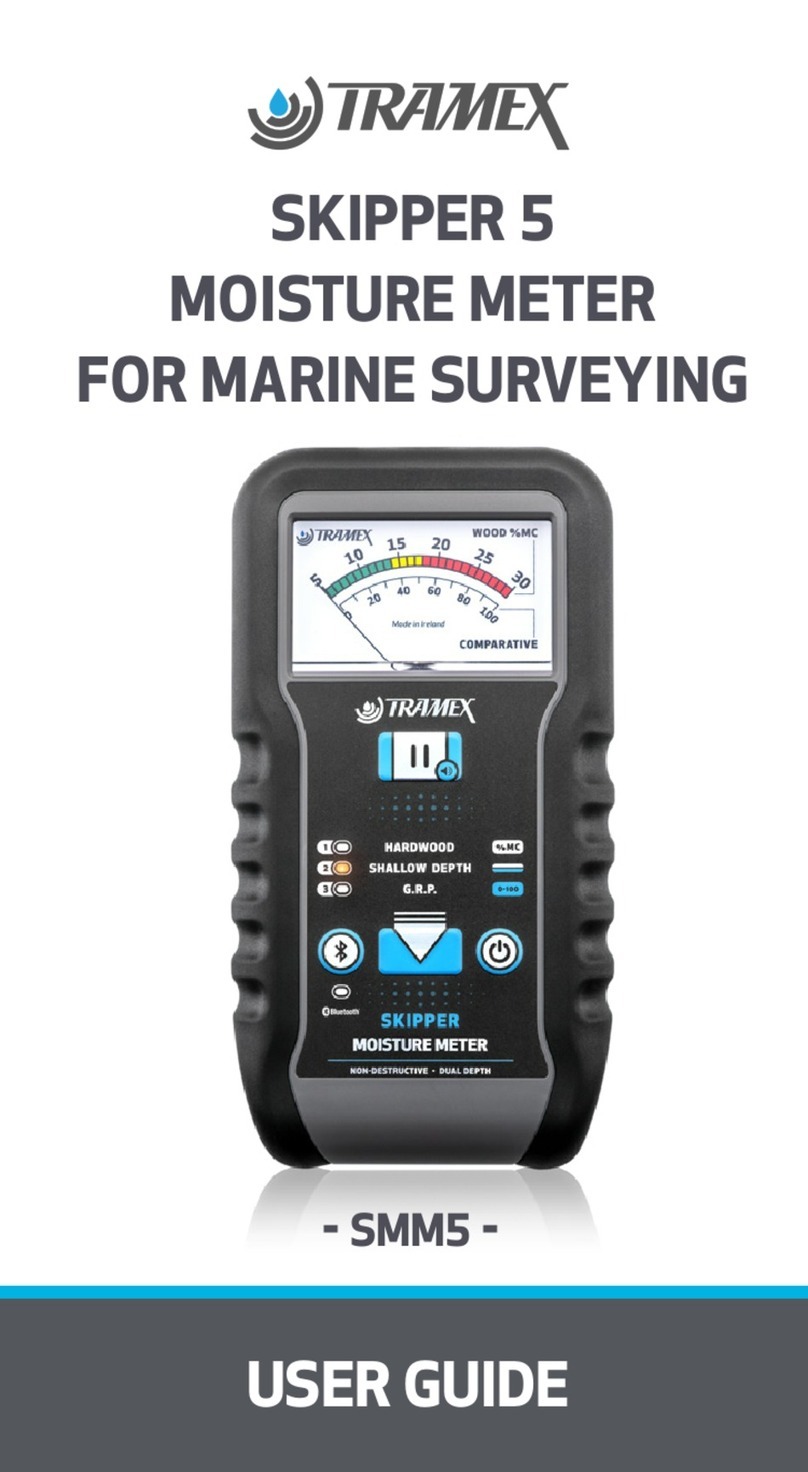

TRAMEX SKIPPER 5 User manual

TRAMEX

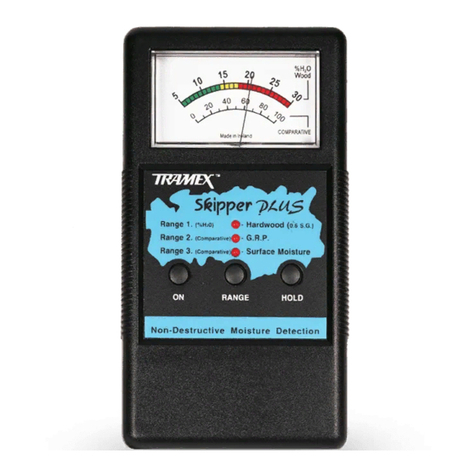

TRAMEX Skipper Plus User manual

TRAMEX

TRAMEX CME 4 User manual

TRAMEX

TRAMEX CME5 User manual

TRAMEX

TRAMEX SKIPPER 5 User manual

TRAMEX

TRAMEX MRH III User manual

TRAMEX

TRAMEX PROFESSIONAL PTM 2.0 User manual

TRAMEX

TRAMEX Skipper Plus User manual

TRAMEX

TRAMEX CME 4 User manual

TRAMEX

TRAMEX ME5 User manual

TRAMEX

TRAMEX CME 4 User manual

TRAMEX

TRAMEX CME5 User manual

TRAMEX

TRAMEX ME5 User manual

TRAMEX

TRAMEX ME5 User manual

TRAMEX

TRAMEX MEX5 User manual

TRAMEX

TRAMEX MEP User manual