- 7 -

■Star delta starting

1). Notes on star delta start

There are three electromagnetic contactor type and two magnetic contactor type in

the star delta starting method. 2 Electromagnetic contactor type circuit is simple and

economical, but since voltage is constantly applied to the windings of the motor even

when the motor is stopped, safety during maintenance and inspection, dust and

humidity are high Because it is necessary to pay attention to insulation degradation

between the windings of each motor phase winding and winding to ground at the

place, 3 electromagnetic contact type is recommended.

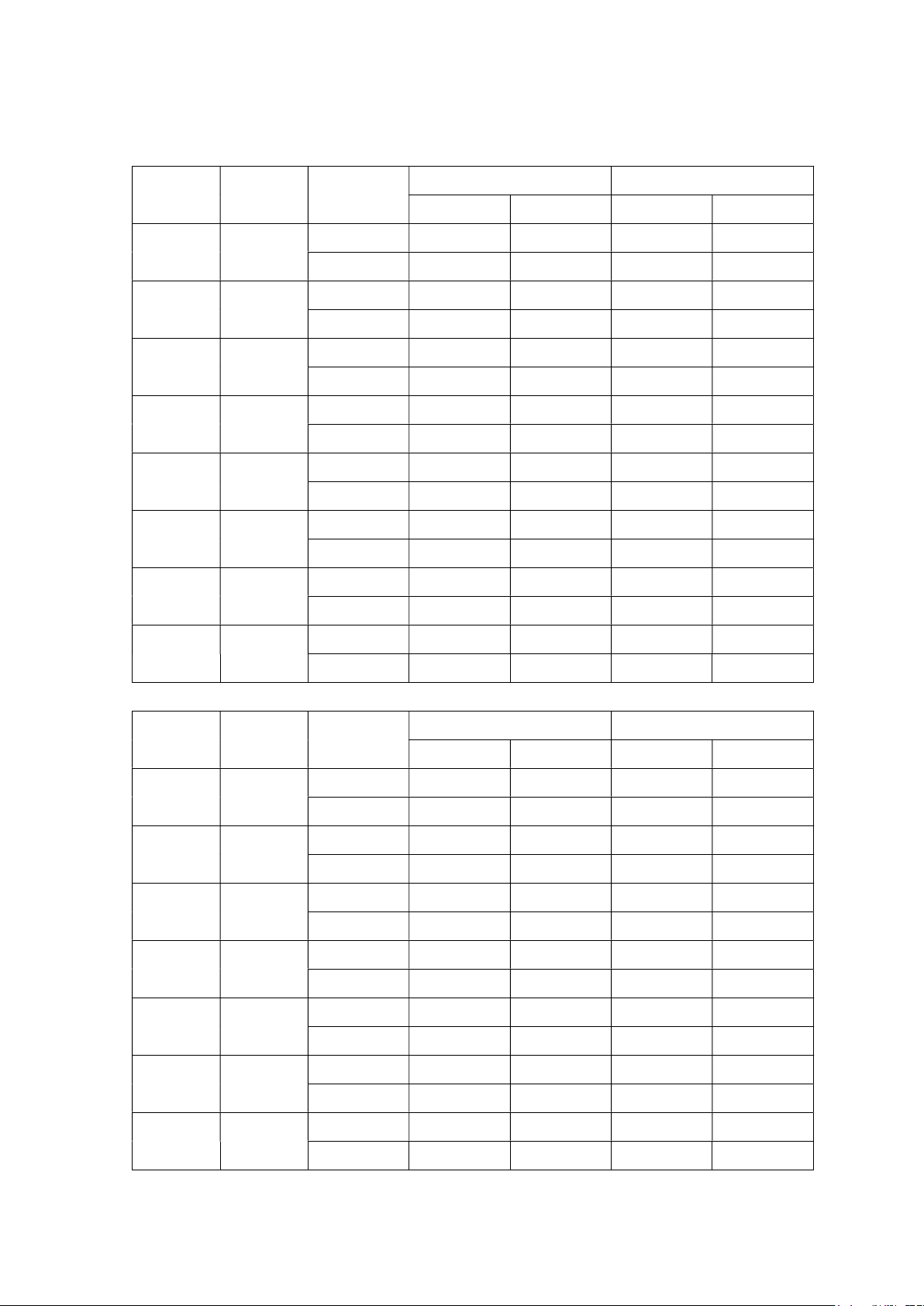

2). Current detection method of thermal relay

As shown in the figure below, the thermal relay at the star delta start has the line

current detection method and the phase current detection method, and the selection

of the heater rating is different. In the line current detection method, the heater

rating is selected based on the motor full load current. On the other hand, in the

phase current detection method, the heater rating is selected based on the current of

1 / √3 of the full load current of the motor. In this method, the frame size of the

thermal relay can be made smaller than that of the line current detection method,

but since the wiring size of the motor circuit does not change in any detection method,

in the case of the phase current detection method, Since it is necessary to consider

whether wire connection is possible or not, the line current detection method is

recommended.

Line current detection method Phase current detection method