SAFETY GUIDELINE

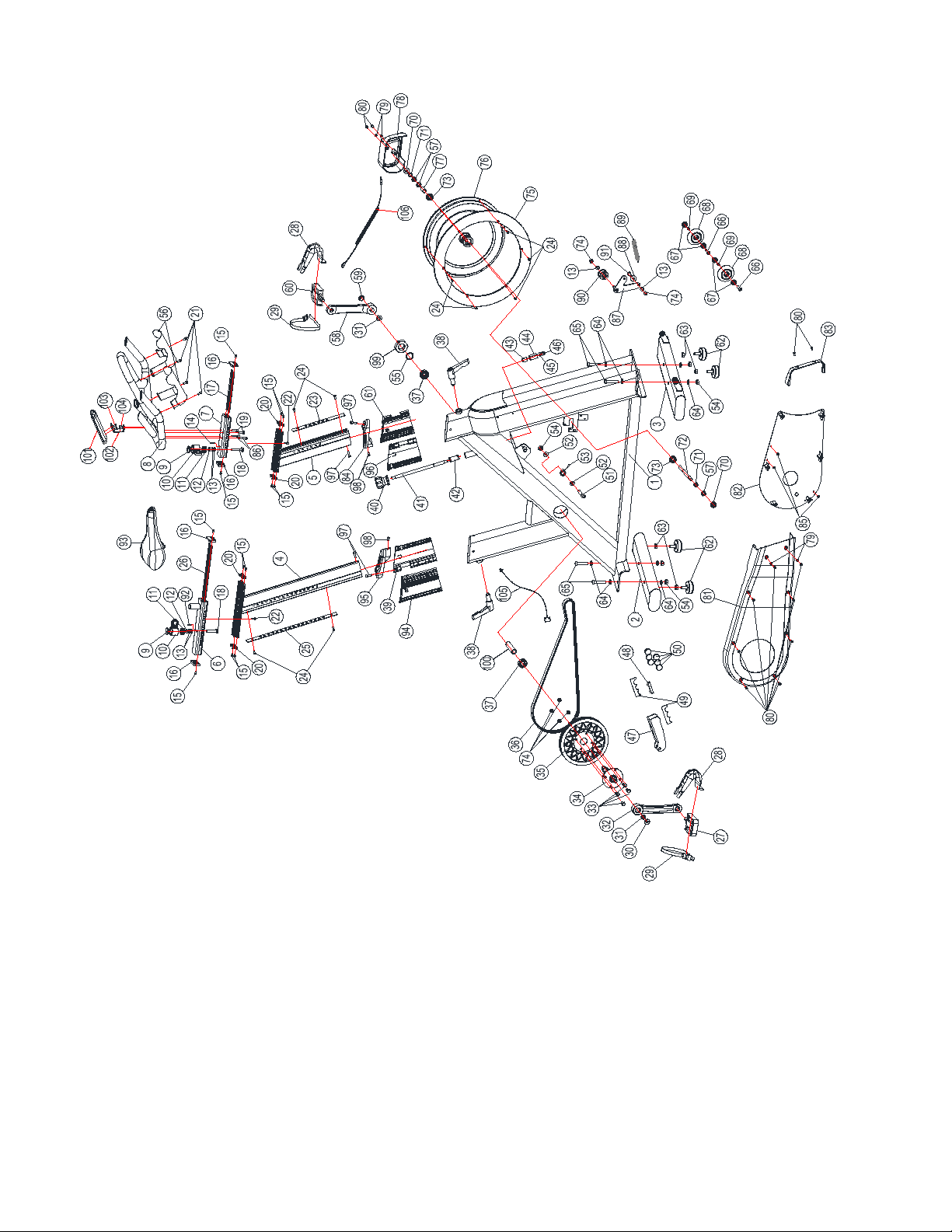

Regular maintenance of the bike should be performed and is essential to keep your Spin bikes in top

operating condition. Without preventative maintenance, normal wear and tear may cause cumulative effects,

such as misalignment or early replacement of parts.

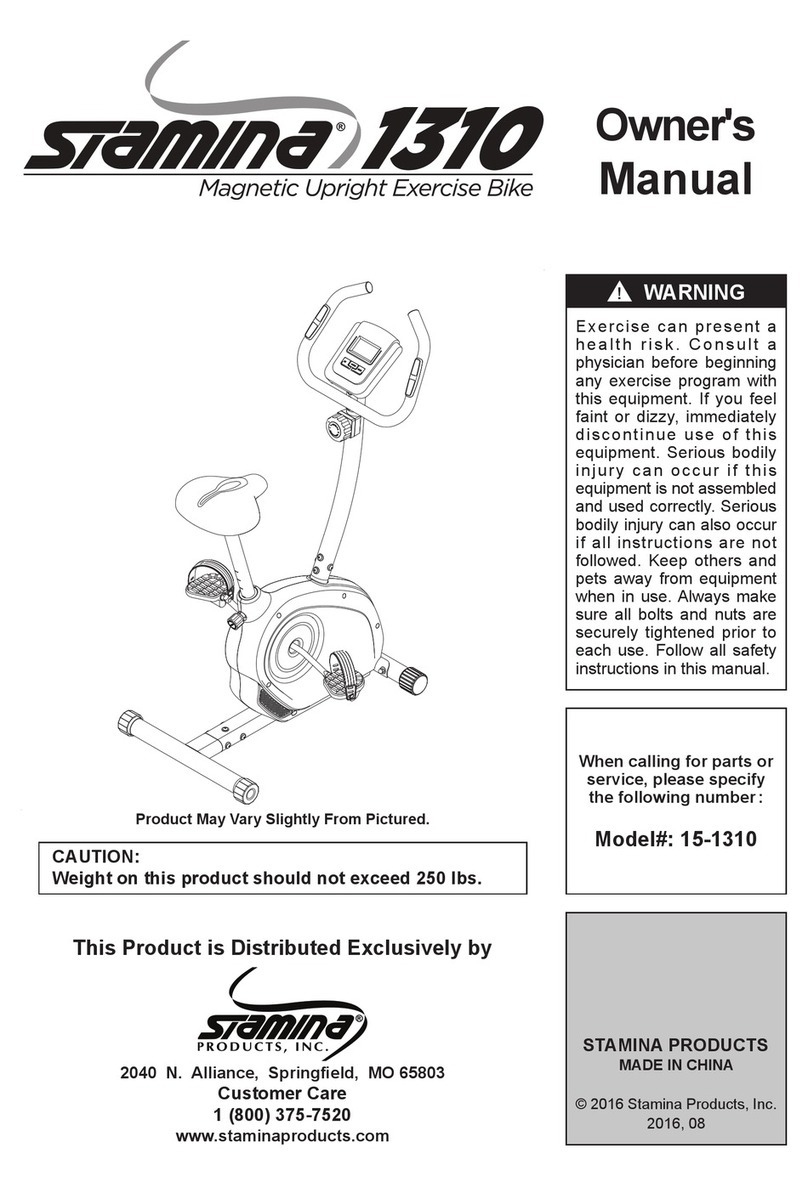

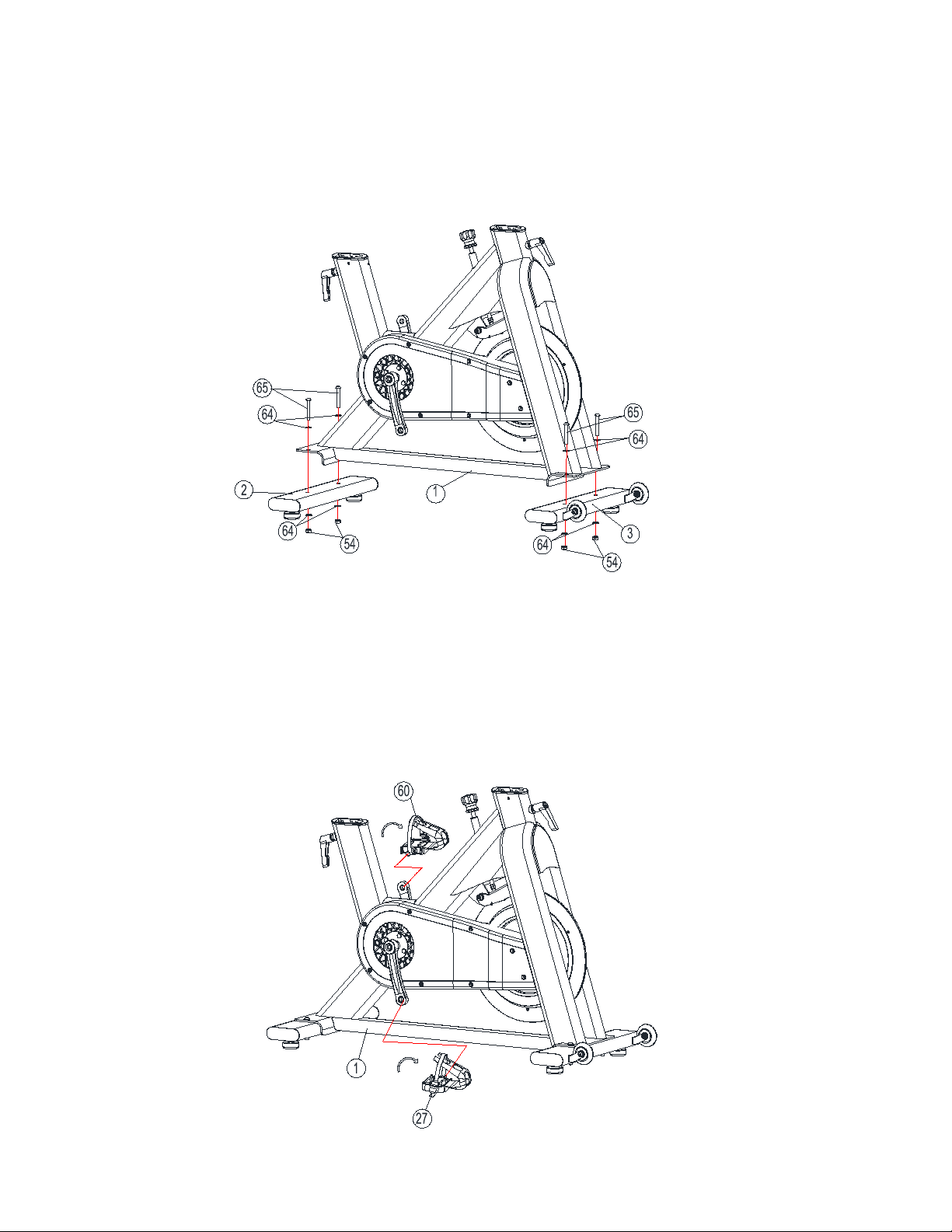

1. Once assembled, please inspect to ensure that all hardware parts such as bolts, nuts and washers are

positioned and correctly.

2. Be sure to wear shoes when exercising, and tighten pedal cage and straps.When using SPD shoes, make

sure that the buckle is fully inserted.Do not remove your foot from the pedal while the bike is still in

motion. If your facility allows members to interchange pedals, it is critical that the pedals are checked

after each class to prevent damage and possible injury.

3. We recommend lubricating all moving parts on a monthly basis.

4. Water bottle cages are easily damaged during class when over-sized bottles are forced to fit within them.

Checking and tightening the screws will help prevent damage.

5. Wipe down the bike at the end of each class. Consider using mildly alkaline cleaning or neutral cleaning

liquids, never use water or oil based cleaning liquids when wiping down the bike.

6. Please keep children away while riding, the bike is designed for adults, and is not suitable for children.

7. If you have any pain or tightness in your chest, an irregular heartbeat, shortness of breath, feel faint or

have any discomfort while you exercise, STOP!

8. Do not place fingers or any other objects into moving parts of the exercise equipment. Do not wear loose

clothes, in case any possible parts getting involved.

9. Before starting any exercise program, consult with your physician first. He or she can help establish the

exercise frequency, time and intensity appropriate for your particular age and condition.

10. After exercising, please turn the adjustment control knob clockwise (+) to increase tension so the pedals

will not rotate freely and possibly hurt someone.

11. This spin bike has passed the standard test of EN 957-1:2005 and EN 957-10:2005, suitable for

commercial use. The max user weight should be within 150kg, and should use under surveillance.