16xx Geyser 58L-ed4010

16xx GEYSER 58 7

3. Installation

3.1. Goods receiving

The appliance is delivered assembled on a pallet and protected by a

plastic film and/or a cardboard box.

1. Position the pallet with the appliance close to the installation

final destination. Move the pallet only with suitable means, such

as a fork-lift.

2. Remove the packaging material and separate the cardboard

from the plastic. Dispose or recycle the cardboard and plastic

according to local norms.

3. Unscrew the bolts that secure the appliance to the pallet

4. Move the appliance from the pallet to its final position.

WARNING – The appliance can be moved by

hand only by experienced personnel. Wear

gloves, safety hat and safety shoes to move the appliance.

3.2. What’s inside the packing

The packing contains:

1. The appliance equipped with all its components.

2. User manual.

When receiving the goods, make sure that the packing contains all

the above listed items.

3.3. Electrical connections

WARNING - The electrical connection is to be made by

a licensed electrician only and according to local safety

regulations.

The manufacturer is not responsible for damage or injury caused by

improper installation.

1. Install a multi-pole switch (circuit breaker) to facilitate installa-

tion and service operations. See table 3.5 for rating and type of

connection.

2. In most countries the circuit breaker should include a pro-

tection against overcurrents (e.g. thermal-magnetic circuit

breaker or fuse). If using a fuse, see power absorption on

the identification plate of the appliance (see figure 2.1).

In some countries the circuit breaker must include a ground

fault interrupt protection.

3. If the appliance is not provided with power cord, mount a cord

of suitable length. For the choice of the cord type refer to table

3.5.

4. Mount a plug on the power cord, see table 3.5 for rating.

5. Connect the plug to the circuit breaker. The cable should hang

in a gentle curve.

WARNING -The electrical line must be properly grounded

to insure the safety of the operator.

INDICATION - If a Ground Fault Interrupt protection is in-

stalled: every month test the safety of the circuit by press-

ing the Test button of the circuit breaker. The protection ought

to trip. If it does not, call a technician immediately, as the safety

of the equipment is impaired.

Table 3.5 - Data for electric connection

Type Plug Power cord

1638

IEC 60309 plug

3P+N+T 400V 3N 100 A

Type H05VV-F

5 x 25mm2

1645

1672 Type H05VV-F

5 x 35mm2

WARNING - The power cord can be replaced only by an

authorised service center.

3.4. Water and steam connections

CAUTION – The connections must be performed by a

qualified technician according to the local regulations in

force.

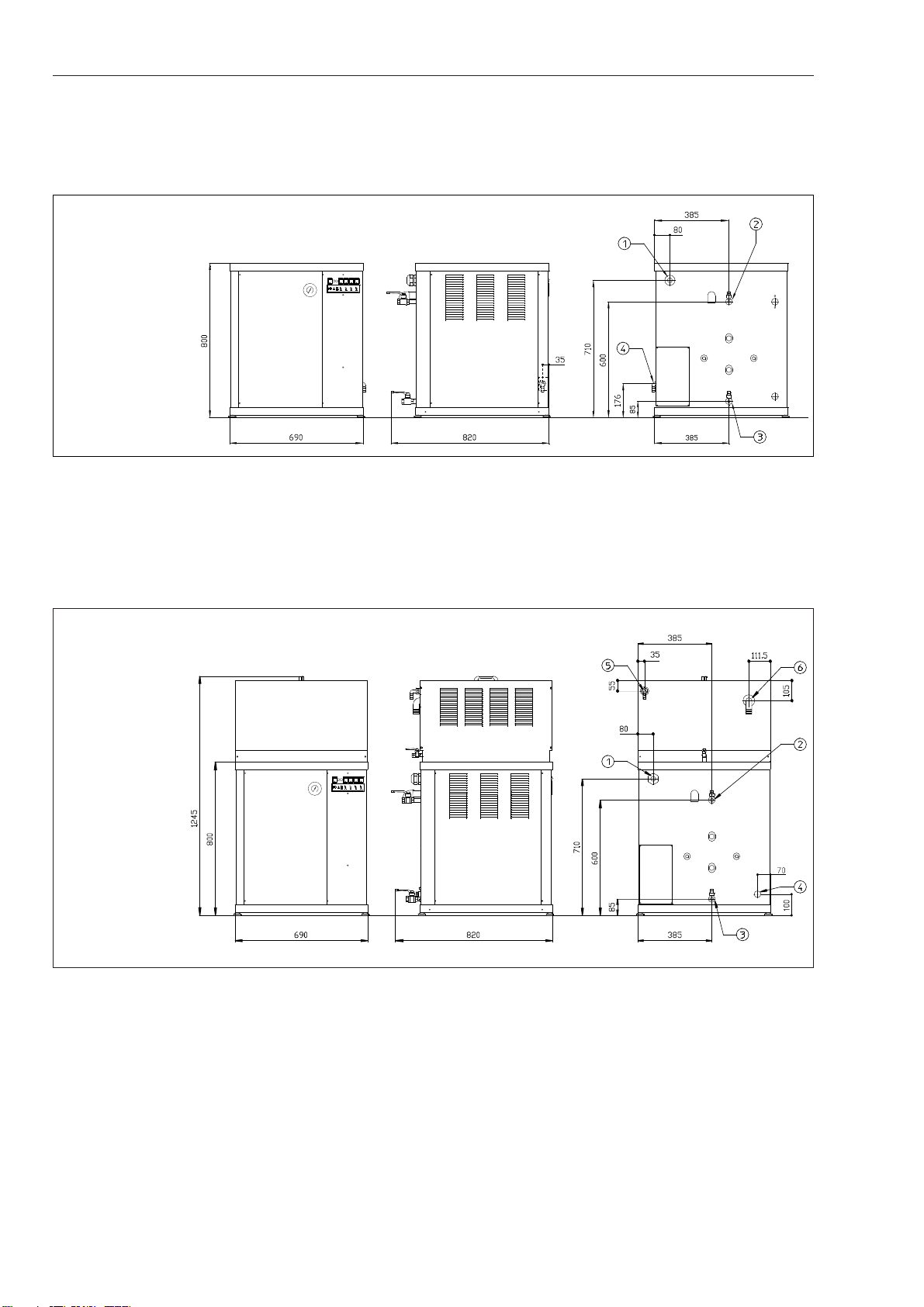

Please refer to Pictures 3.1 and 3.2.

1. Connect the boiler discharge outlet C to a safe and permanent

connection, that can stand heat.

WARNING - The connection must ensure that no

leakage of steam or hot water occurs during the

boiler discharge operation

2. Connect the water inlet E to the water supply line.

• install a non-return valve* and a faucet or ball valve on

the water mains

• for the connection use a 16mm diameter tube rated for

the pressure of the water mains in your area*.

*For EU countries: these items must be approved according to

standard EN 61770.

WARNING - Use tap water. Do not add softening

products.

3. If the appliance is equipped with the top tank for condensate

recovery: connect the overflow of the tank F to a drain line.

WARNING - Water that overflows from the tank may

reach 80°C: choose a suitable pipe.

4. Connect the steam outlet B to the steam distribution plant.

WARNING – The steam distribution line must be rat-

ed to stand a working pressure of 800 kPa.

5. If the appliance is equipped with the top tank for condensate

recovery: connect the condensate return line to the condensate

inlet D on the tank. For convenience we suggest to install a

valve able to interrupt the flow of condensate.

6. Thermally insulate all the pipes that carry hot water or steam

(i.e. all the pipes except for the tube that feeds water).

7. If necessary, install tanks or devices that allow hot water to cool

before reaching the drainage system.

3.5. Training of the operator

The technician must instruct the operator on how to drain the boiler.

The operator must be advised that:

• during the operation, the boiler expels hot water mixed to

steam;

• the operation can be carried out only if the pressure in the boil-

er is below 1 bar;

• the connection to the drainage system must be kept in good

order and must be verified every time before performing the

procedures.

Installation