Operation Manual HORIBA APDA-371

Particulate Monitor

Date: April, 2010

______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

HORIBA Europe GmbH, Julius-Kronenberg-Str. 9, D-42799 Leichlingen,

: +49(0)2175-8978-0,

: +49(0)2175-8978-50

Page 8

The APDA-371 is shipped with two white foam rings and a white plastic shim inside the front of the unit, which prevent

the moving parts of the tape control assembly from being damaged in transit. Do not remove the foam rings until the

APDA-371 is ready to be installed. These rings must be replaced anytime the unit is being transported in order to avoid

damaging the tape control mechanism.

Please keep the special box and foam packing material that the APDA-371 was shipped in, to re-use in the event that

you must return the unit to the factory. HORIBA is not responsible for any damages to the unit if returned in non-original

packaging, or without the foam rings in place. Contact HORIBA for replacement packing materials if necessary.

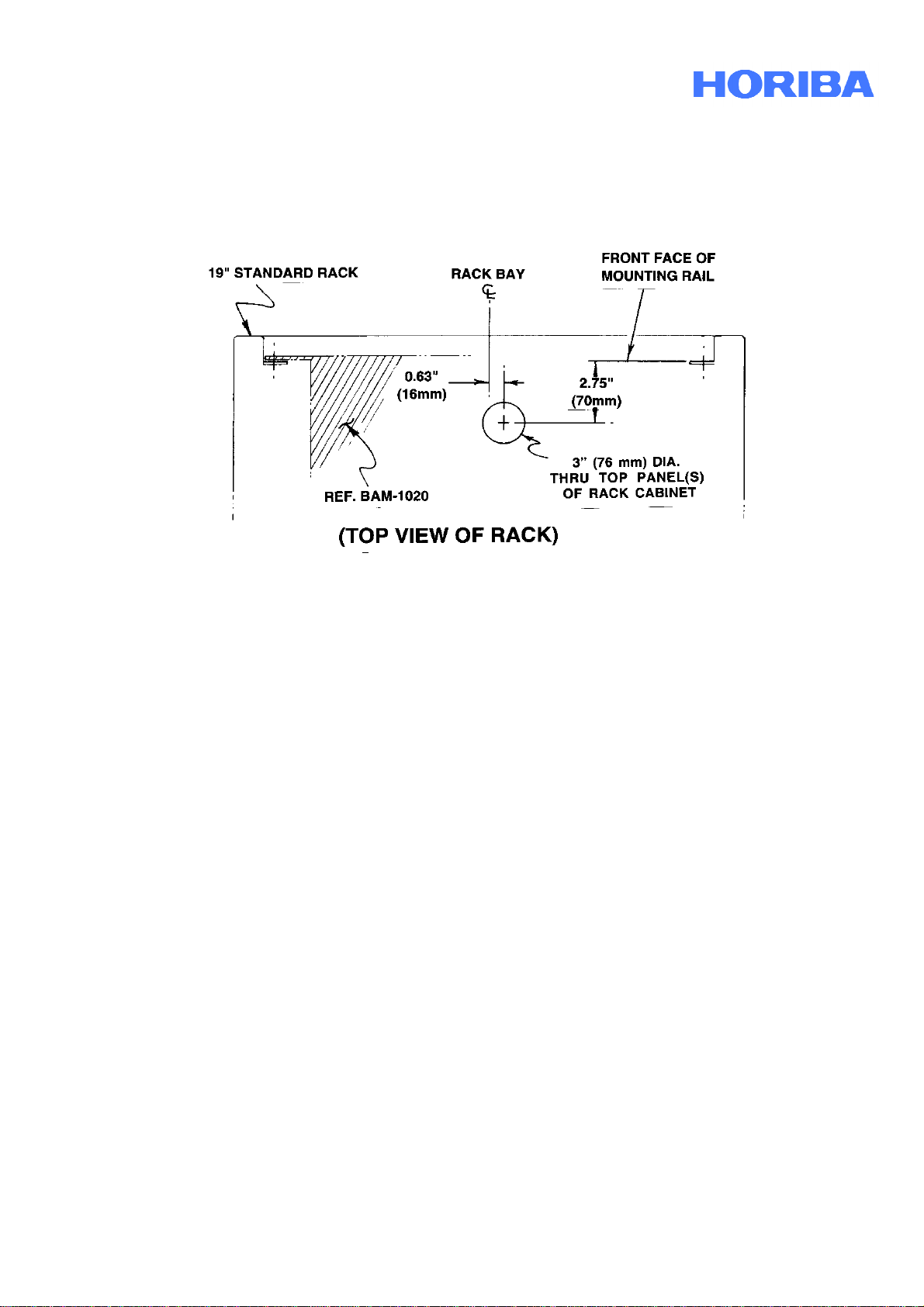

2.2 Enclosure Selection

The APDA-371 unit is not weatherproof or water resistant, and is designed to be mounted in a weatherproof, level,

vibration free, dust free, and temperature controlled environment where the operating temperature is between 0o C and

+50o C, and where the relative humidity is non-condensing and does not exceed 90%. There are two standard

configurations described below for providing a weatherproof location in which to install the unit. Please contact HORIBA

if you plan to have a non-standard mounting or enclosure configuration.

1. A walk-in building or mobile shelter with a flat roof: This is often a pre-fabricated shelter, a trailer shelter, or

a room in an existing permanent building. The APDA is mounted on a bench-top or in an equipment rack, often with a

variety of other instruments installed in the same shelter. The inlet tube of the APDA must extend up through the roof

with appropriate hardware. AC power must be available. Instructions for this type of installation are included in this

section of the manual.

2. BX-902/903 environmentally controlled mini enclosure: Sometimes nicknamed “dog house” enclosures,

these small pre-fabricated enclosure are just big enough for the APDA and related accessories, and are installed on the

ground or on the roof of a larger building. They are available with a heater (BX-902), or with a heater and air conditioner

(BX-903). These enclosures are custom designed by HORIBA to accept the APDA-371, and are supplied with a

supplemental setup and installation manual.

NOTE: The air temperature inside any enclosure in which a APDA-371 is installed must be held as constant as possible

over the course of the hour. This is important because the unit measures the beta particles through a small gap of air

around the filter tape at the beginning and the end of each hour. If the air temperature inside the enclosure has changed

by more than about 2 degrees C during this time, the concentration measurement can be affected on the order of

several micrograms. HORIBA recommends logging the air temperature inside the enclosure to monitor this effect. The

exact temperature is not critical as long as it fluctuates as little as possible during any one hour.

2.3 Site Selection

Selection of a proper site for the APDA-371 is critical for accurate measurements. In many cases, these items must be

correctly addressed in order for the collected data to be acceptable for regulatory requirements, such as EPA PM

10

and

PM

2.5

equivalent methods. Specifications for the site selection can be found in EPA document EPA-450/4-87-007 May

1987 “Ambient Monitoring Guidelines for Prevention of Significant Deterioration”, as well as 40 CFR, Part 58. In any

case, the Code of Federal Regulations takes precedence.

Inlet Height:

•The inlet should be located in the “breathing zone”, between 2 and 15 meters above ground level. If the APDA

is to be installed in an enclosure at ground level, then the inlet height must two meters or greater above the

ground.

•If the inlet is located on (or through) a rooftop, the total height should be no more than 15 meters from the

ground level. The inlet height should be two meters above roof surface of the building that the unit is installed

in. This matches the specified inlet height of most FRM samplers.

•If the APDA-371 is to be co-located with other particulate instruments, such as FRM filter-based samplers or

other APDA units, then the air inlet must be the same height as the inlet of the other samplers.

•The BX-902 and BX-903 environmental shelters are designed to locate the inlet two meters above whatever

surface they are placed on.

•Make sure to account for the height of the PM

10

and/or PM

2.5

heads when planning the inlet tube length.

HORIBA can supply a variety of tube lengths up to 8-feet long.

•The maximum allowable total inlet tube length is 16 feet between the APDA-371 and the bottom of the inlet