Horne Engineering Ltd

Issue 7, November 2018 6

Allow the shower to run at maximum temperature setting until the water temperature has stabilised.

Should the temperature rise, or drop, in an uncontrolled fashion, then

the hot and cold supplies are probably reversed. Correct this before

proceeding.

The TSV1-3 is set in the factory to provide a maximum outlet

temperature of approximately 41°C, but this should be checked on site

to ensure that the setting has not been altered, and to ensure user

safety. If necessary, reset the maximum outlet temperature to 41°C.

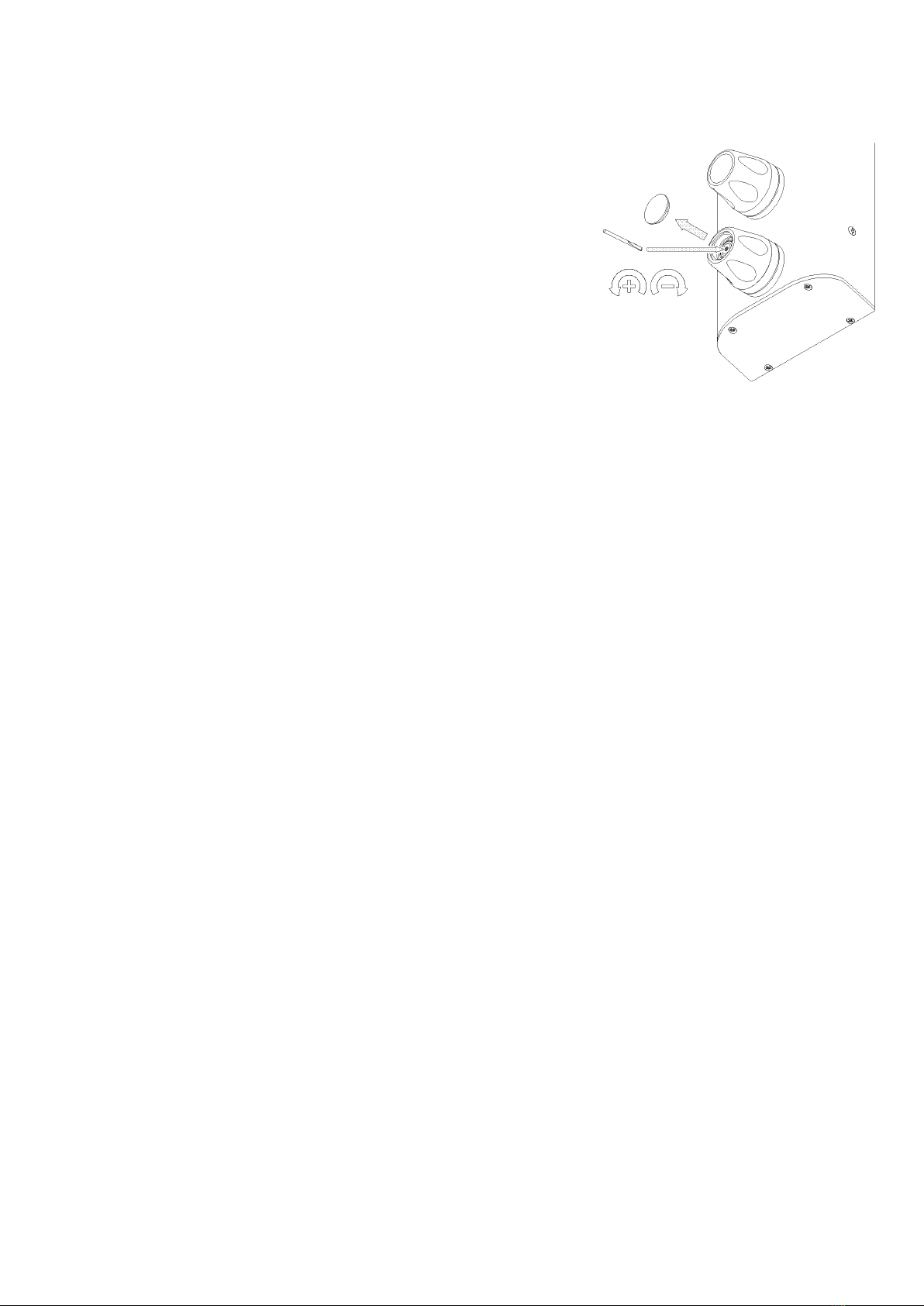

If the maximum temperature requires adjustment, remove the

temperature control cap using a small plastic spudger or blade and

adjust the small slotted screw in the centre of the spindle. Adjust the

screw anticlockwise to increase the temperature, clockwise to

decrease the temperature. See Fig 8.

Fig 8

After setting the maximum temperature, turn the shower on and off a few times and check that the

maximum setting is correct. Note that the final stabilised Mixed Water Temperature should not exceed 43C

to comply with DO8. Record the commissioning information, including equipment used, on the attached

commissioning sheet to permit the in-service performance of the valve to be assessed at a later date.

Finally, check the thermal shut-off facility of the TSV1-3 by performing a thermal shut off test (often called

a cold fail test). With the shower running, close the cold (i.e. right hand) servicing valve. The Servicing

Valve is closed when the arrows are in the horizontal position, and open when they are in the vertical

position. See Fig 6. The flow from the shower head should immediately stop or reduce to a trickle, in

which case the mixed water temperature rise should be less than 2°C above the set temperature. In either

case, there is no scalding risk. If the temperature rises above this then it is likely that there is

contamination in the TSV1-3 that is preventing it from shutting off the hot supply. Restore the supply and

note the final stabilised temperature, which should not exceed 43°C.

Refer to the maintenance section of this booklet or phone the factory for advice, if necessary.

MAINTENANCE

Maintenance of the TSV1-3 shower valve is essential to ensure the product continues to perform to

specification after installation, and continues to afford scald protection. Record all maintenance carried out

on the attached commissioning and maintenance record.

When cleaning the external faceplates and knobs, never use cleaners containing abrasives or solvents as

they may damage the chrome plating. Use only a soft cloth and soap.

The frequency of routine maintenance of the TSV1-3 internals (i.e. cleaning, descaling etc) depends

largely on the condition of the water supplies, and local knowledge will dictate suitable intervals. In

addition to this the following precautions should be observed.

Initially check the strainer baskets for debris every three months and clean if required. This period can be

increased if appropriate once the general condition and cleanliness of the water is established.

Perform a thermal shut-off test every three months, and check the maximum temperature setting. See the

last paragraph in the Commissioning Instructions for details of the thermal shut-off test and re-adjustment

of the maximum temperature setting, if required.

If the maximum water temperature rises by more than 2K (2°C) from the commissioned setting then

ensure that the strainers are clean and that the isolating valves are fully open. Test the Check Valves as

described below. If these tests do not highlight the reason for the temperature rise then follow the

procedure below for investigating failure of the thermal shut-off test.