4

Example circuit diagrams for some typical installations are shown below. These diagrams are

schematic and should be used as a guide only.

Please ensure that all installations comply with the current IEE regulations.

For reasons of space and clarity not every system has been included and the diagrams have been

simplified (for example some earth connections have been omitted)

Other control components shown in the diagrams i.e. valves, room stats etc are general

representations only. However the wiring detail can be applied to the corresponding models of most

manufacturers, e.g. Horstmann, Honeywell, Danfoss Randall, ACL Drayton etc.

Cylinder and Room Thermostat Key:

C = Common CALL = Call for heat or break on rise SAT = Satisfied on rise N = Neutral

Typical wiring diagrams

54

Example circuit diagrams for some

typical installations are shown below.

These diagrams are schematic and

should be used as a guide only.

Please ensure that all installations

comply with the current IEE

regulations.

For reasons of space and clarity not

every system has been included and

the diagrams have been simplified

(for example some earth connections

have been omitted)

Other control components shown

in the diagrams i.e. valves, room

stats etc are general representations

only. However the wiring detail can

be applied to the corresponding

models of most manufacturers, e.g.

Horstmann, Honeywell, Danfoss

Randall, ACL Drayton etc.

Cylinder and Room Thermostat

Key:

C = Common CALL = Call for heat

or break on rise

SAT = Satisfied on rise

N = Neutral

Typical wiring diagrams

NL123456

E

E

N

L

N L

MAINS

SUPPLY

COMBINATION BOILER TERMINALS

FOR PRECISE TERMINAL

CONNECTION INFORMATION

PLEASE REFER TO BOILER

MANUFACTURER INSTRUCTIONS

TERMINALS L - 5

SHOULD NOT

BE LINKED

REMOVE

LINK IF

FITTED

ROOM

STAT

CALL SAT

N C

BOILER LIVE OUT

E

N

L

MAINS

SUPPLY

NL123456

ROOM

STAT

CYL

STAT

CALL

CALL

N N

L L

BOILER PUMP

SAT

SAT

N C

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

ZONE

VALVE

N C

CYL

STAT

CALL

CALL

SAT

SAT

C

NL

PUMP &

BOILER

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

CYL

STAT

CALL SAT

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

CYL

STAT

CALL SAT

C

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL SAT

BR

BL

W

GR

0

CALL SAT

C

N N

L L

BOILER PUMP

ROOM

STAT

CYL

STAT

ZONE VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

W

BL

0

GR

MID POSITION

VALVE

NL

PUMP &

BOILER

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

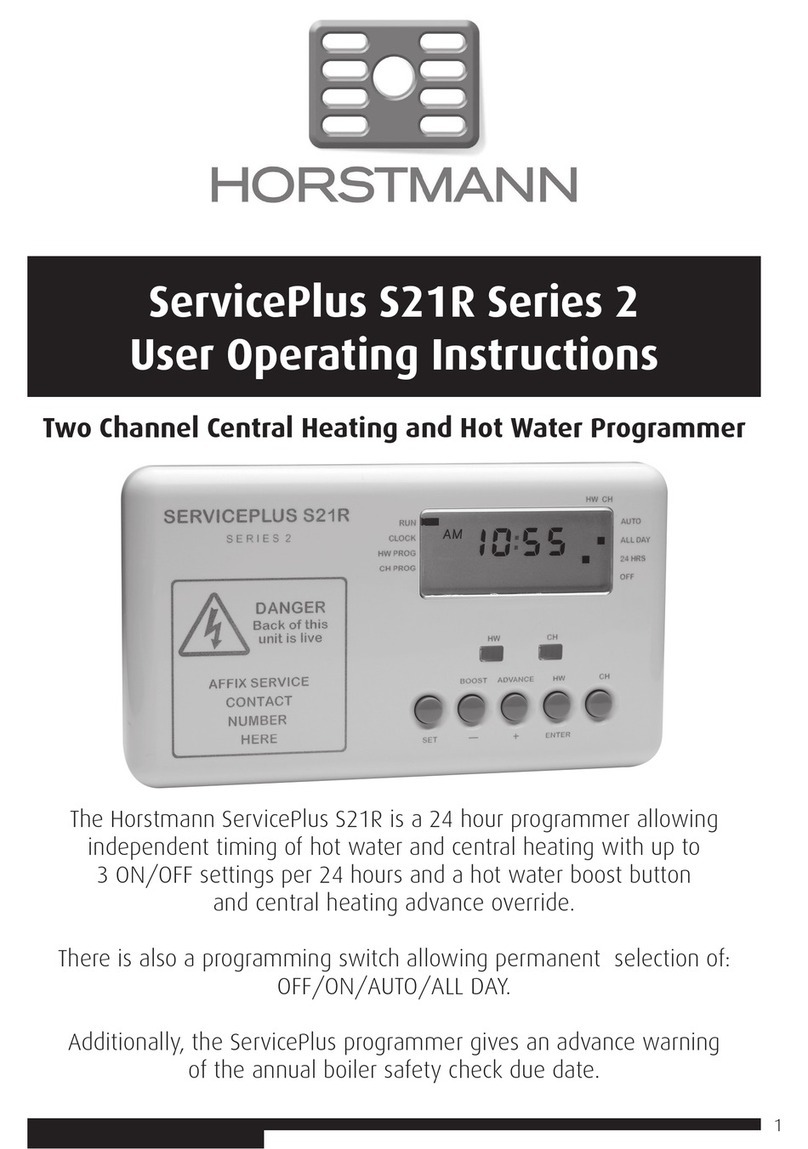

425 Coronet controlling typical combination boiler

installation via room thermostat.

425 Tiara controlling fully pumped system using two

motorised 2 port valves with auxiliary switches via

room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Coronet controlling gravity hot water with

pumped heating via room stat and cylinder stat.

Fully pumped system using roomstat and two (2 port)

spring return zone valve with auxiliary switches.

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Coronet controlling fully pumped system via room

stat,cylinder stat and using a 2 port spring return valve

with auxiliary switch on heating circuit.

425 Tiara controlling fully pumped system using a mid

position valve via room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating using a 2 port spring return valve with

changeover auxiliary switch on the hot water circuit.

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE

54

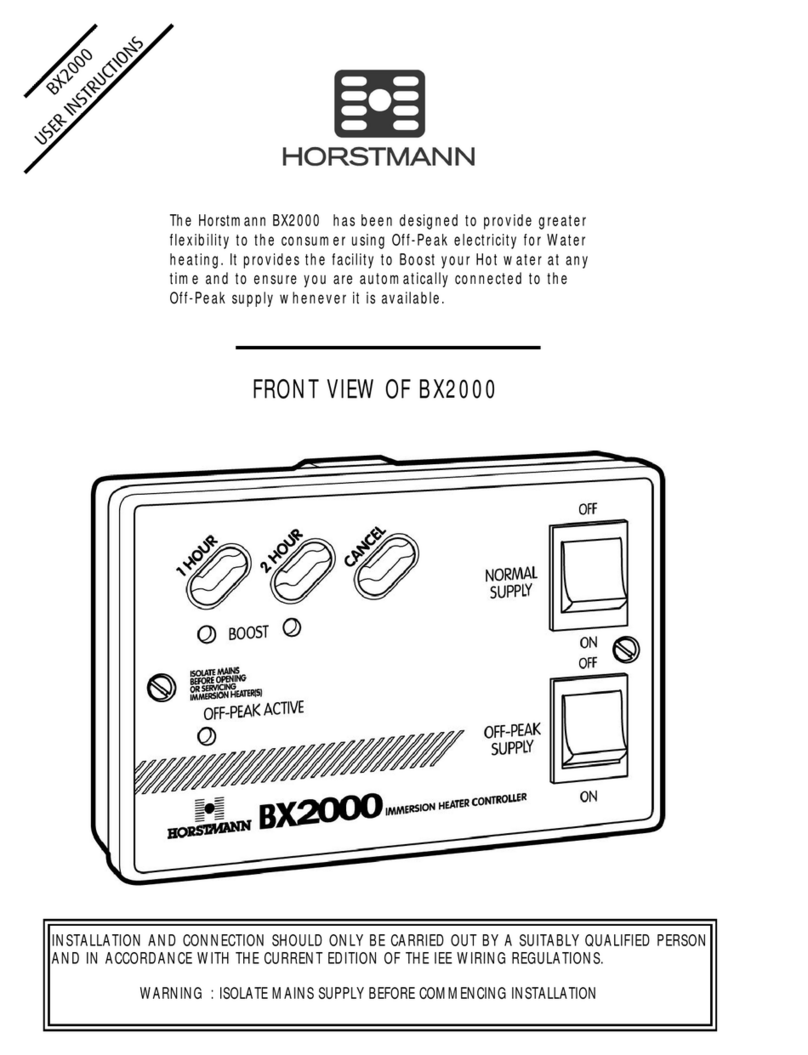

Example circuit diagrams for some

typical installations are shown below.

These diagrams are schematic and

should be used as a guide only.

Please ensure that all installations

comply with the current IEE

regulations.

For reasons of space and clarity not

every system has been included and

the diagrams have been simplified

(for example some earth connections

have been omitted)

Other control components shown

in the diagrams i.e. valves, room

stats etc are general representations

only. However the wiring detail can

be applied to the corresponding

models of most manufacturers, e.g.

Horstmann, Honeywell, Danfoss

Randall, ACL Drayton etc.

Cylinder and Room Thermostat

Key:

C = Common CALL = Call for heat

or break on rise

SAT = Satisfied on rise

N = Neutral

Typical wiring diagrams NL123456

E

E

N

L

N L

MAINS

SUPPLY

COMBINATION BOILER TERMINALS

FOR PRECISE TERMINAL

CONNECTION INFORMATION

PLEASE REFER TO BOILER

MANUFACTURER INSTRUCTIONS

TERMINALS L - 5

SHOULD NOT

BE LINKED

REMOVE

LINK IF

FITTED

ROOM

STAT

CALL SAT

N C

BOILER LIVE OUT

E

N

L

MAINS

SUPPLY

NL123456

ROOM

STAT

CYL

STAT

CALL

CALL

N N

L L

BOILER PUMP

SAT

SAT

N C

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

ZONE

VALVE

N C

CYL

STAT

CALL

CALL

SAT

SAT

C

NL

PUMP &

BOILER

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

CYL

STAT

CALL SAT

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

CYL

STAT

CALL SAT

C

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL SAT

BR

BL

W

GR

0

CALL SAT

C

N N

L L

BOILER PUMP

ROOM

STAT

CYL

STAT

ZONE VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

W

BL

0

GR

MID POSITION

VALVE

NL

PUMP &

BOILER

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

425 Coronet controlling typical combination boiler

installation via room thermostat.

425 Tiara controlling fully pumped system using two

motorised 2 port valves with auxiliary switches via

room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat

425 Coronet controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Tiara controlling fully pumped system using room

stat and two (2 port) spring return zone valve with

auxiliary switches

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Coronet controlling fully pumped system via room

stat,cylinder stat and using a 2 port spring return valve

with auxiliary switch on heating circuit.

425 Tiara controlling fully pumped system using a mid

position valve via room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating using a 2 port spring return valve with

changeover auxiliary switch on the hot water circuit.

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE

54

Example circuit diagrams for some

typical installations are shown below.

These diagrams are schematic and

should be used as a guide only.

Please ensure that all installations

comply with the current IEE

regulations.

For reasons of space and clarity not

every system has been included and

the diagrams have been simplified

(for example some earth connections

have been omitted)

Other control components shown

in the diagrams i.e. valves, room

stats etc are general representations

only. However the wiring detail can

be applied to the corresponding

models of most manufacturers, e.g.

Horstmann, Honeywell, Danfoss

Randall, ACL Drayton etc.

Cylinder and Room Thermostat

Key:

C = Common CALL = Call for heat

or break on rise

SAT = Satisfied on rise

N = Neutral

Typical wiring diagrams NL123456

E

E

N

L

N L

MAINS

SUPPLY

COMBINATION BOILER TERMINALS

FOR PRECISE TERMINAL

CONNECTION INFORMATION

PLEASE REFER TO BOILER

MANUFACTURER INSTRUCTIONS

TERMINALS L - 5

SHOULD NOT

BE LINKED

REMOVE

LINK IF

FITTED

ROOM

STAT

CALL SAT

N C

BOILER LIVE OUT

E

N

L

MAINS

SUPPLY

NL123456

ROOM

STAT

CYL

STAT

CALL

CALL

N N

L L

BOILER PUMP

SAT

SAT

N C

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

ZONE

VALVE

N C

CYL

STAT

CALL

CALL

SAT

SAT

C

NL

PUMP &

BOILER

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

N N

L L

BOILER PUMP

CYL

STAT

CALL SAT

C

E

N

L

MAINS

SUPPLY

NL12345 6

ROOM

STAT

N C

CALL SAT

CYL

STAT

CALL SAT

C

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL SAT

BR

BL

W

GR

0

CALL SAT

C

N N

L L

BOILER PUMP

ROOM

STAT

CYL

STAT

ZONE VALVE

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

W

BL

0

GR

MID POSITION

VALVE

NL

PUMP &

BOILER

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

425 Coronet controlling typical combination boiler

installation via room thermostat.

425 Tiara controlling fully pumped system using two

motorised 2 port valves with auxiliary switches via

room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat

425 Coronet controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Tiara controlling fully pumped system using room

stat and two (2 port) spring return zone valve with

auxiliary switches

425 Diadem/Tiara controlling gravity hot water with

pumped heating via room stat and cylinder stat.

425 Coronet controlling fully pumped system via room

stat,cylinder stat and using a 2 port spring return valve

with auxiliary switch on heating circuit.

425 Tiara controlling fully pumped system using a mid

position valve via room stat and cylinder stat.

425 Diadem/Tiara controlling gravity hot water with

pumped heating using a 2 port spring return valve with

changeover auxiliary switch on the hot water circuit.

E

N

L

MAINS

SUPPLY

NL12345 6

N C

CALL

SAT

CALL SAT

C

FROST

STAT

IF

FITTED

C

CALL

ROOM

STAT

CYL

STAT

NL

PUMP &

BOILER

ZONE

VALVE

ZONE

VALVE