EN - 9

English

3GENERAL INFORMATION

3.1 Use of the manual

This manual forms an integral part of the appliance and should be

kept for future reference. Please read it carefully before installing/

using the unit If the appliance is sold, the Seller must pass on this

manual to the new owner along with the appliance.

3.2 Delivery

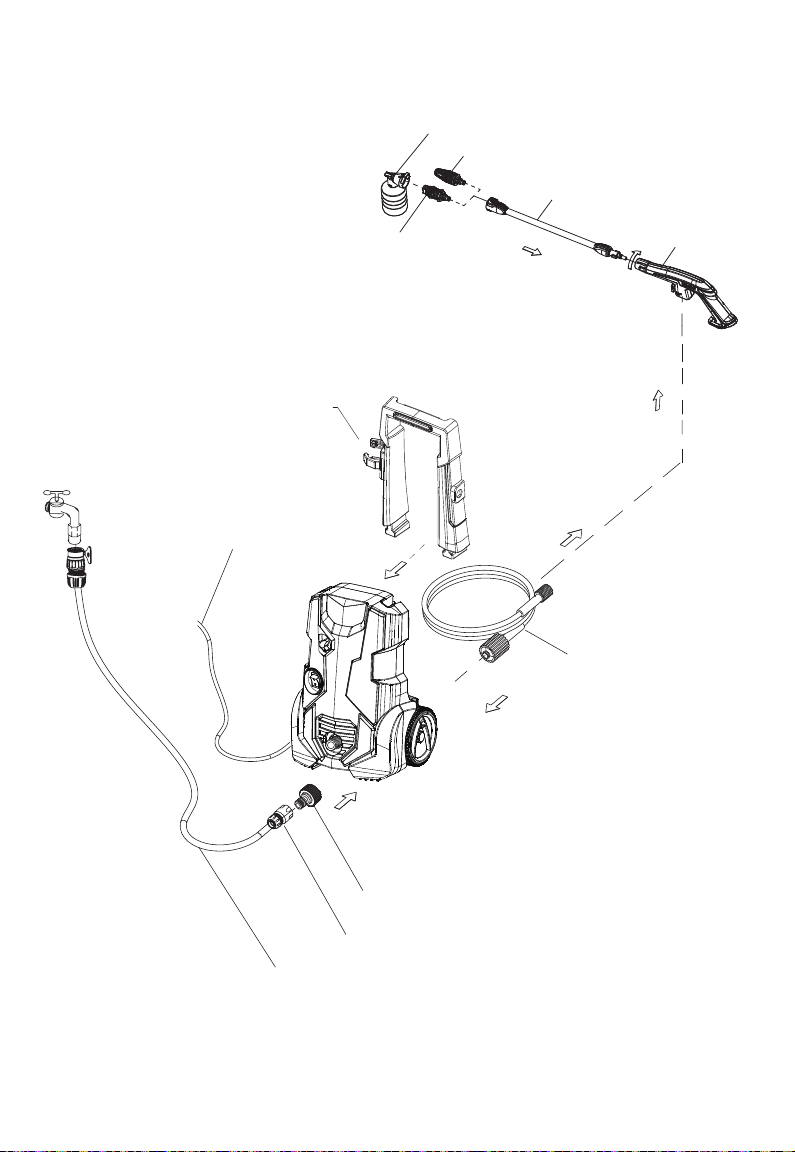

The appliance is delivered partially assembled in a cardboard box.

The supply package is illustrated in g.1.

3.2.1 Documentation supplied with the appliance

A1 Use and maintenance manual

A2 Safety instructions

A3 Declaration of conformity

A4 Warranty regulations

3.3 Disposing of packaging

The packaging materials are not environmental pollutants but must

still be recycled or disposed of in compliance with the relevant

legislation in the country of use.

3.4 Safety signs

Comply with the instructions provided by the safety signs tted to

the appliance.

Check that they are present and legible; otherwise, t replacements

in the original positions.

E1 sign - Indicates that the appliance must not be disposed of as

municipal waste; it may be handed in to the dealer on purchase of a

new appliance. The appliance’s electrical and electronic parts must

not be reused for improper uses since they contain substances

which constitute health hazards.

3.4.1 Symbols

E2 symbol - Indicates that the appliance

is intended for professional use, i.e. for

experienced people informed about the relative

technical, regulatory and legislative aspects and capable

of performing the operations necessary for the use and

maintenance of the appliance.

E3 symbol - Indicates that the appliance is

intended for non-professional (domestic) use.

4TECHNICAL INFORMATION (see data plate)

4.1 Envisaged use

This appliance has been designed for individual use for the cleaning

of vehicles, machines, boats, masonry, etc, to remove stubborn dirt

using clean water and biodegradable chemical detergents.

Vehicle engines may be washed only if the dirty water is disposed

of as per regulations in force.

- Intake water temperature: MAX 40°C

- Intake water pressure: min. 0,1 MPa-max 1MPa.

- Operating ambient temperature: above 0°C.

The appliance is compliant with the EN 60335-2-79/A1 standard.

4.2 Operator

The symbol on the front cover identies the appliance’s intended

operator (professional or non-professional).

4.3 Improper use

Use by unskilled persons or those who have not read and

understood the instructions in the manual is forbidden.

The introduction of inammable, explosive and toxic liquids into the

appliance is prohibited.

Use of the appliance in a potentially inammable or explosive

atmosphere is forbidden.

The use of non-original spare parts and any other spare parts not

specically intended for the model in question is prohibited.

All modications to the appliance are prohibited. Any modications

made to the appliance shall render the Declaration of Conformity

null and void and relieve the manufacturer of all liability under civil

and criminal law.

4.4 Main components

B1 Adjustable spray nozzle

B2 Lance

B3 Gun with safety catch

B4 Power supply cable with plug

B5 High pressure hose

B6 Detergent tank (on models with this feature)

4.5 Safety devices

Caution - Danger!

Do not tamper with or adjust the safety valve setting.

- Safety valve and/or pressure limiting valve.

The safety valve is also a pressure limiting valve.

When the gun trigger is released, the valve opens and the water

recirculates through the pump inlet or is discharged onto the

ground.

- Thermostat valve (D1 where tted)

If the water temperature exceeds the temperature set by the

manufacturer, the thermostat valve discharges the hot water and

draws in an amount of cold water equal to the amount of water

discharged, until the correct temperature is restored.

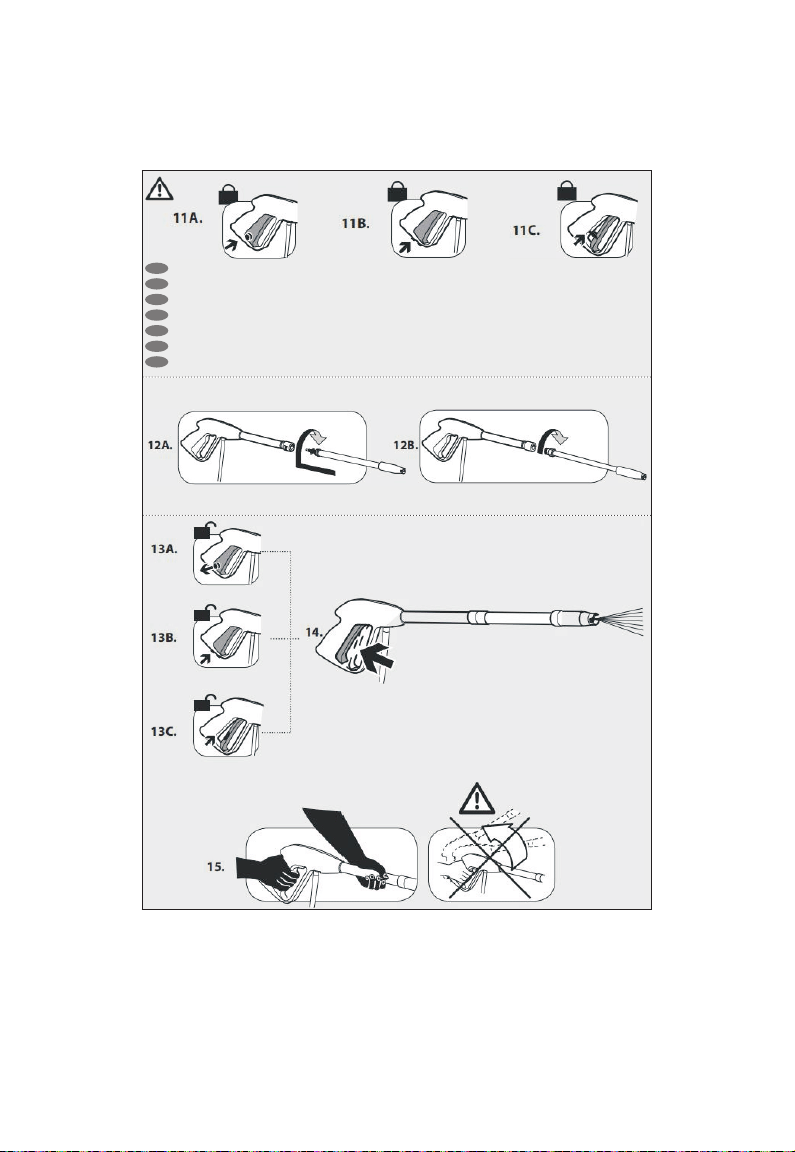

- Safety catch (D): prevents accidental spraying of water.

5INSTALLATION (FIG.2) (A-B-C-D)

5.1 Assembly

Caution - Danger!

All installation and assembly operations must be

performed with the appliance disconnected from the

mains power supply.

The assembly sequence is illustrated in g.1

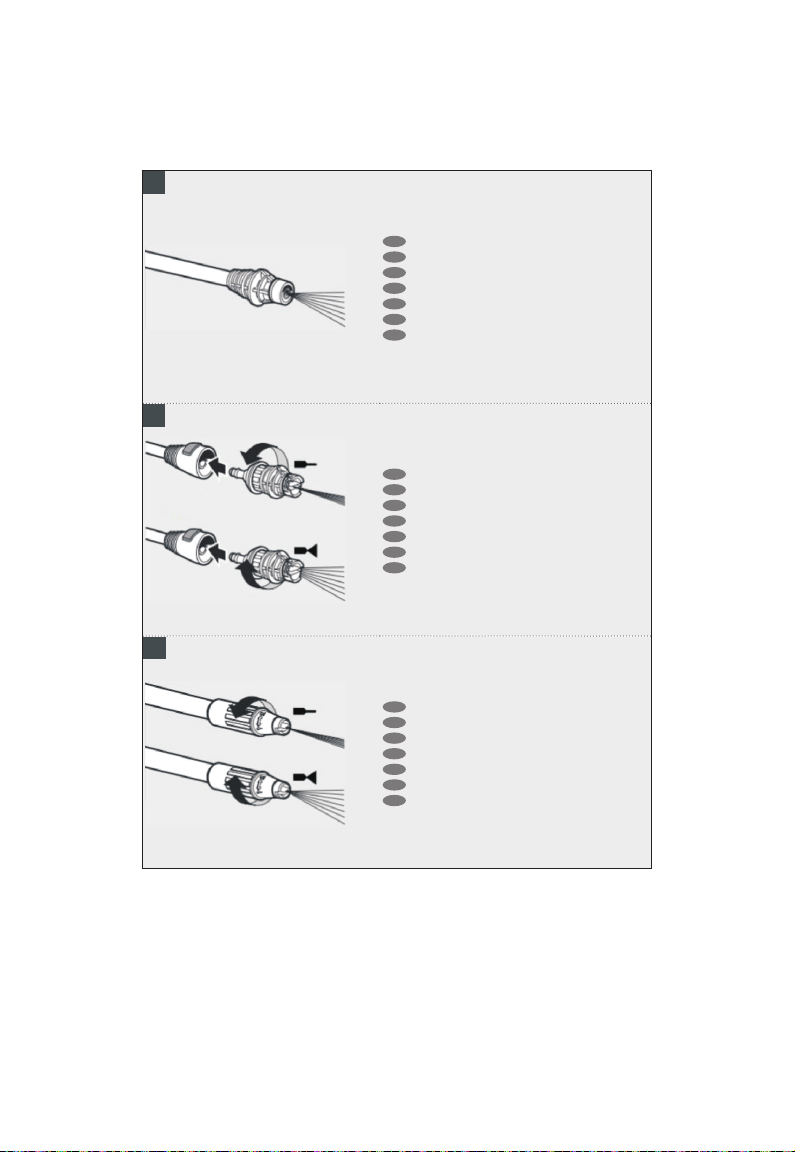

5.2 Assembling the rotating nozzle

(For models with this feature)

The rotating nozzle kit delivers greater washing power.

Use of the rotating nozzle may cause of reduction in pressure of

25% compared to the pressure obtained with the adjustable nozzle.

However, the rotating nozzle kit delivers greater washing power due

to the rotation of the water jet.

5.3 Electrical connection

Caution - Danger!

Check that the electrical supply voltage and frequency

(V-Hz) correspond to those specied on the appliance

data plate. The appliance should only be connected to a mains

power supply equipped with an adequate earth connection and

a differential security breaker (30 mA) to cut off the electricity

supply in the instance of a short circuit.

5.3.1 Use of extension cables

Use cables featuring “IPX5” protection level.

The cross-section of the extension cable should be

proportionate to its length; the longer it is, the greater its

cross-section should be. See table I.

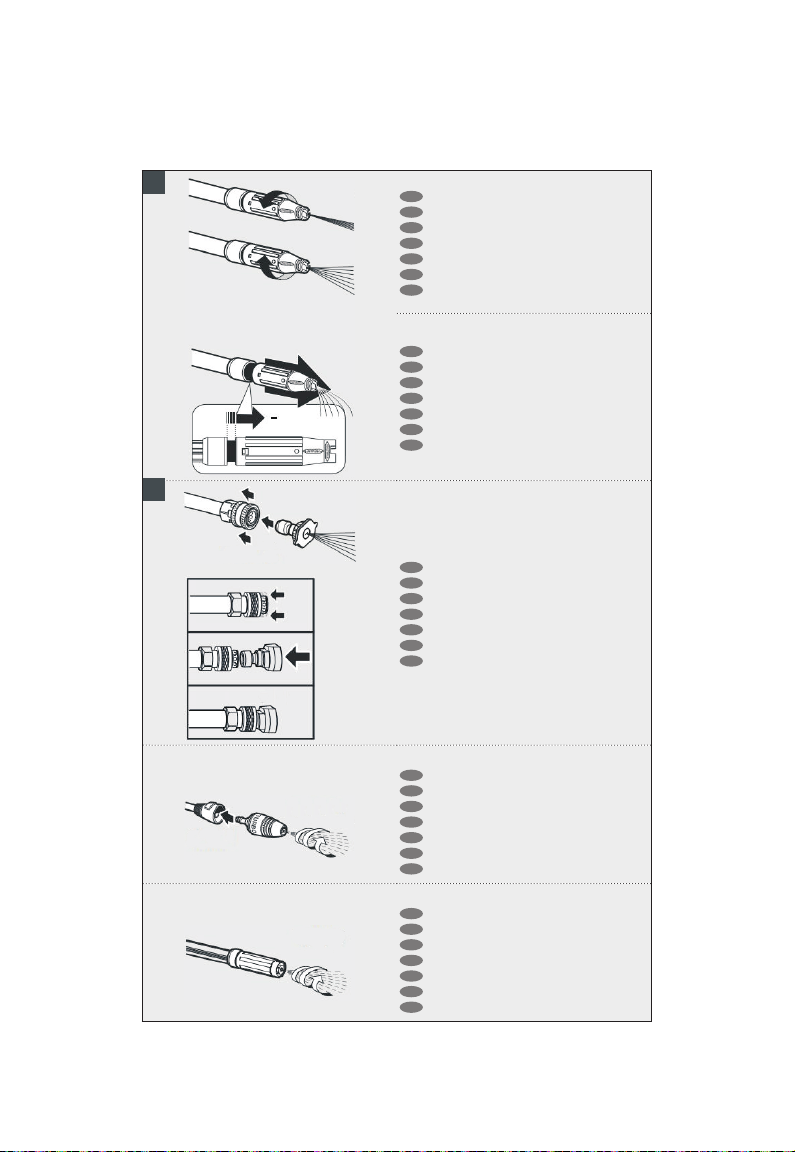

5.4 Water supply connection

Caution - Danger!

Only clean or ltered water should be used for intake.

The delivery of the water intake tap should be equal to

that of pump capacity.

Place the appliance as close to the water supply system as

possible.

5.4.1 Connection points

Water outlet (OUTLET)

Water inlet with lter (INLET)