74MA5270002

CONTENTS PAGE

1. FOR SAFETY AND BEST OPERATING RESULTS----------------------------------------- 1

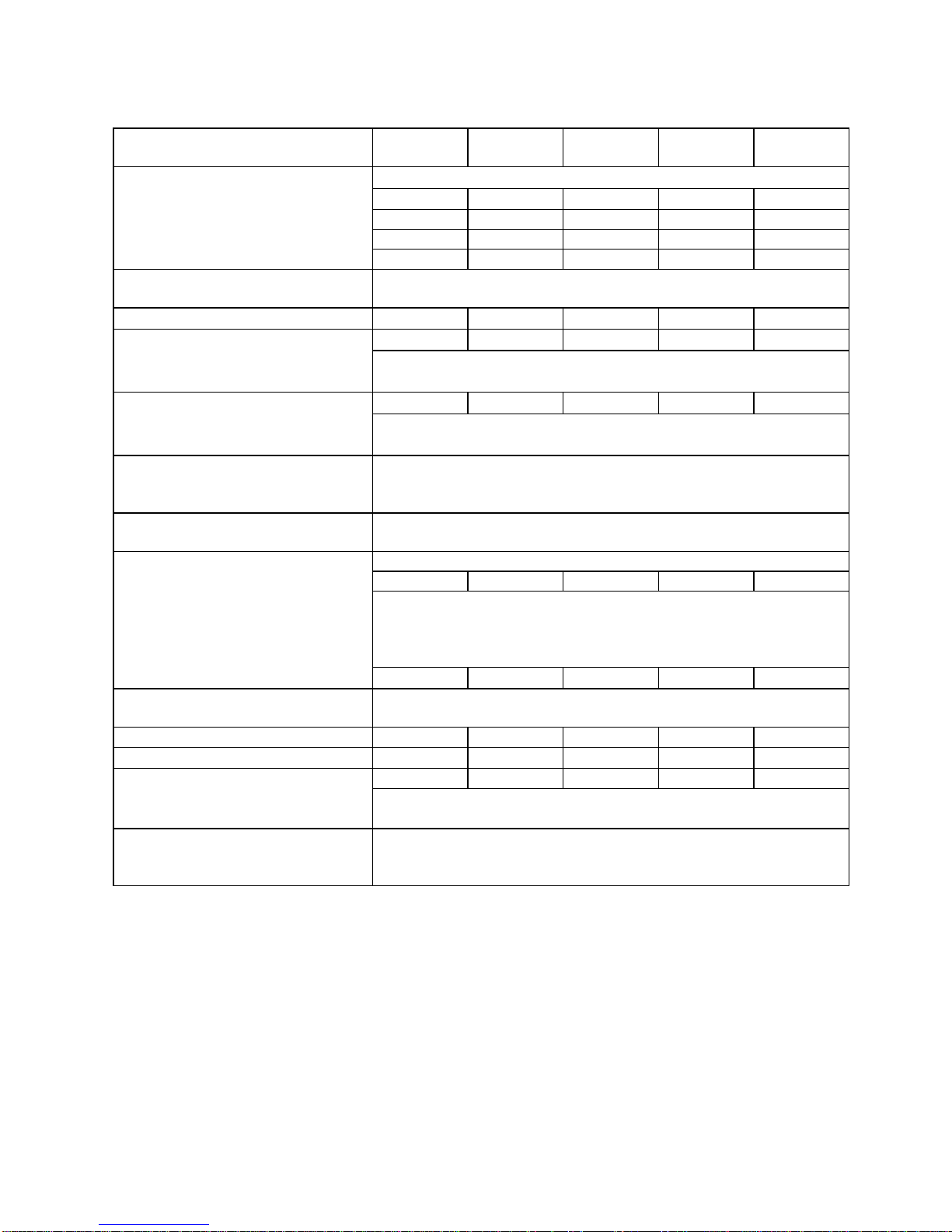

2. SPECIFICATIONS ---------------------------------------------------------------------------------- 2

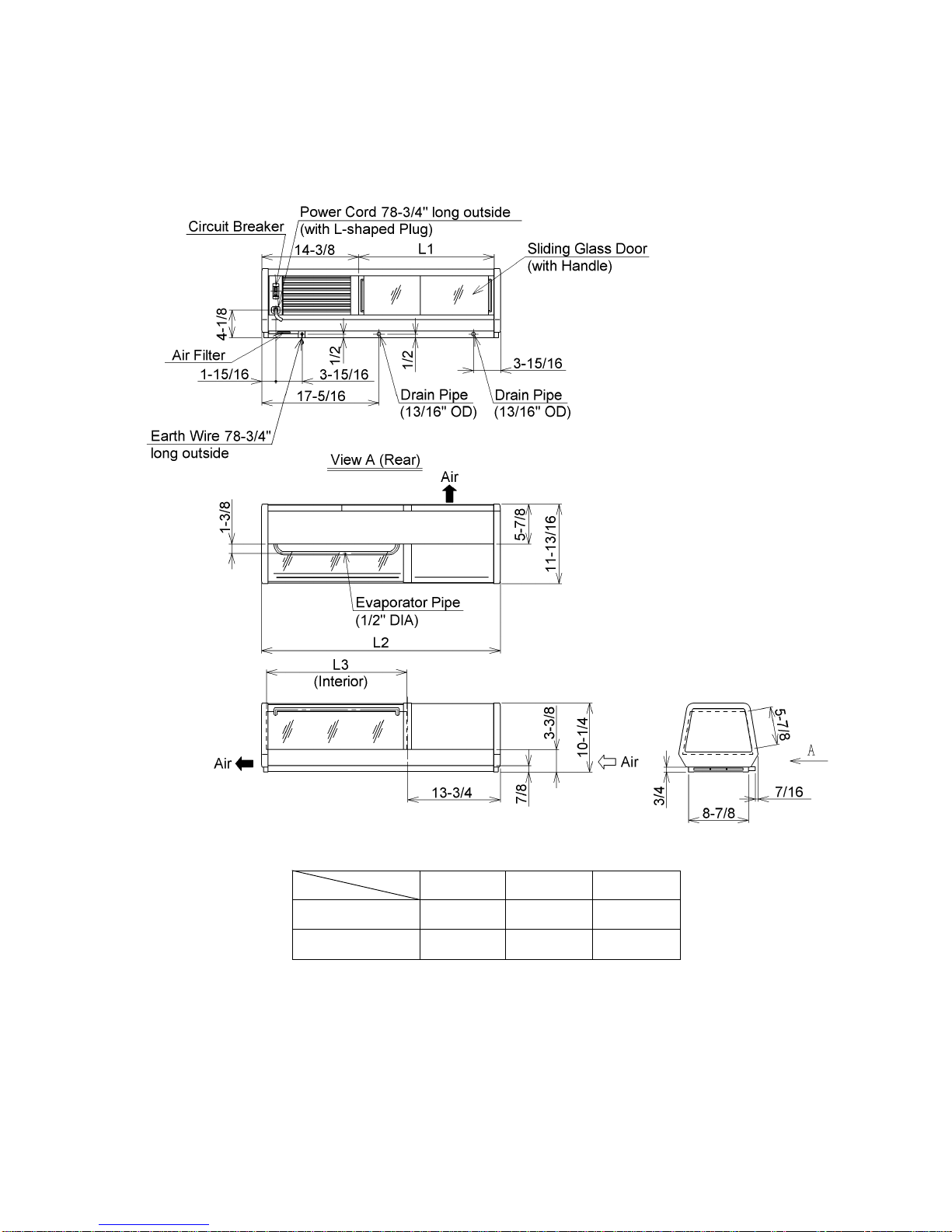

3.DIMENSIONS ---------------------------------------------------------------------------------------- 3

[a] RNC-90A-RA, RNC-120A-RA---------------------------------------------------------------- 3

[b] RNC-150A-RA, RNC-180A-RA, RNC-210A-RA----------------------------------------- 4

[c] RNC-90A-LA, RNC-120A-LA ---------------------------------------------------------------- 5

[d] RNC-150A-LA, RNC-180A-LA, RNC-210A-LA ------------------------------------------ 6

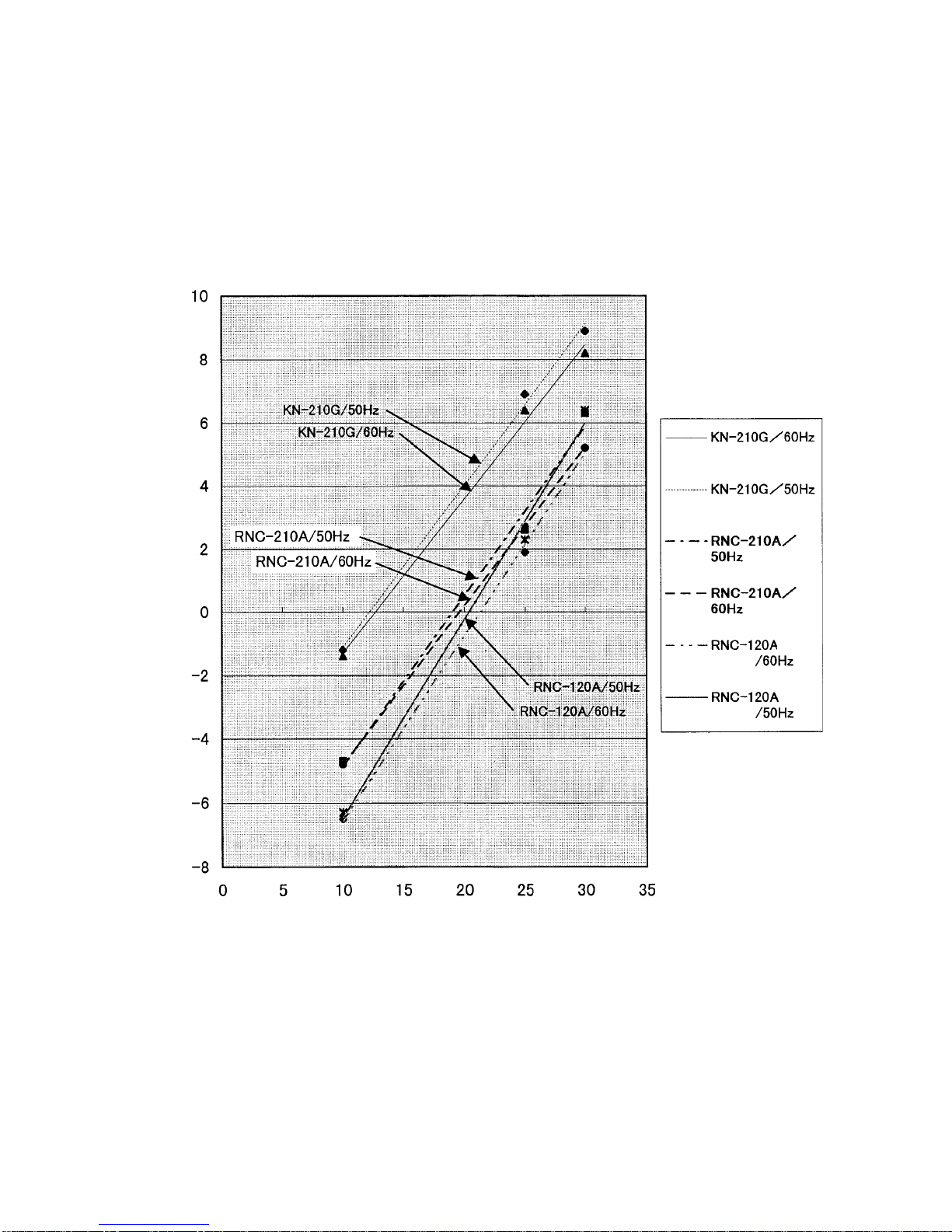

4. PERFORMANCE DATA --------------------------------------------------------------------------- 7

5.REFRIGERATIONCIRCUIT ----------------------------------------------------------------------- 8

6.WIRINGDIAGRAM ---------------------------------------------------------------------------------- 9

7.CONSTRUCTION ----------------------------------------------------------------------------------10

8. REMOVAL AND REPLACEMENT------------------------------------------------------------- 11

[a] FRONT GLASS AND TOP COVER -------------------------------------------------------11

[b] TOP FRAME ------------------------------------------------------------------------------------12

[c] SEPARATOR AND SIDE FRAME ---------------------------------------------------------12

[d] BREAKER COVER AND LOUVER -------------------------------------------------------12

[e] PIPE HOLDER ---------------------------------------------------------------------------------13

[f] WATERPROOF COVER ---------------------------------------------------------------------13

9.REFRIGERANTSERVICEINFORMATION---------------------------------------------------15

10. CONSTANT PRESSURE EXPANSION VALVE AND REFRIGERANT CHARGE --17

[a]SPECIFICATIONS -----------------------------------------------------------------------------17

[b]FUNCTION---------------------------------------------------------------------------------------17

[c]CONSTRUCTION ------------------------------------------------------------------------------17

[d] REPLACEMENT-------------------------------------------------------------------------------18

11. SERVICE DIAGNOSIS----------------------------------------------------------------------------19