SINCO FC-430S Instruction manual

Page 1

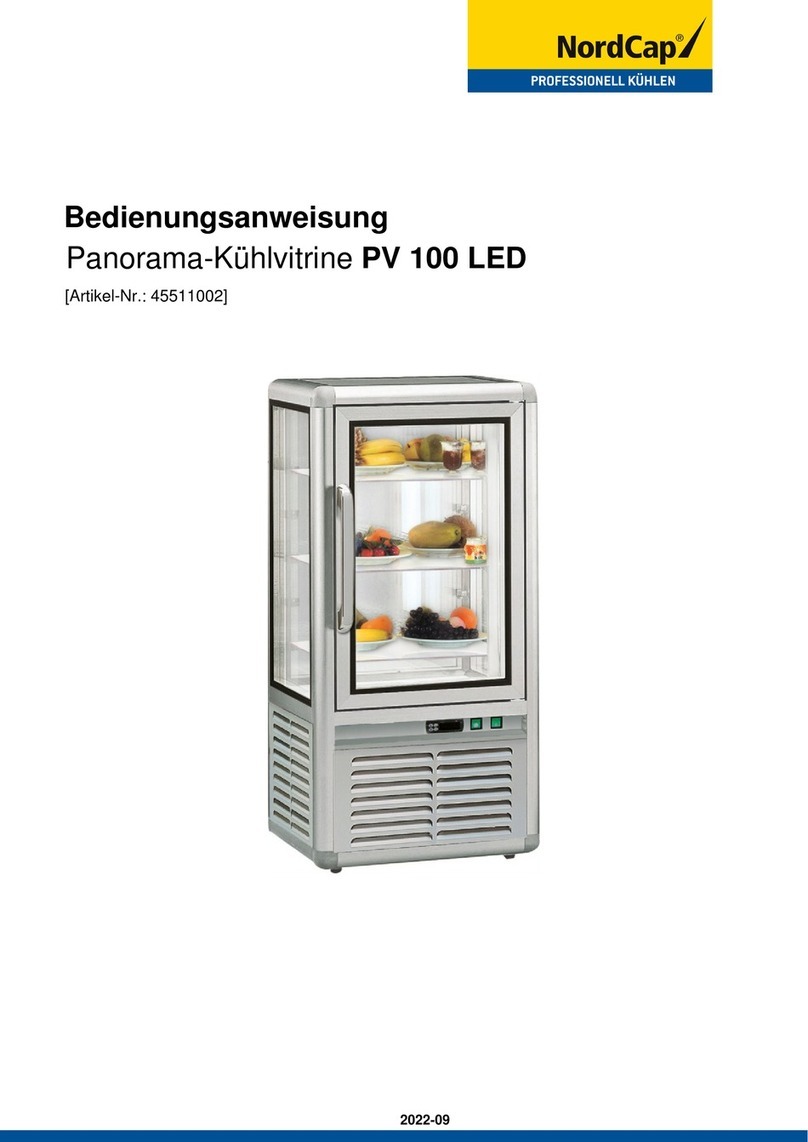

Refrigerated display cabinet

Please read this manual book carefully before use and operate according

to this manual book

Please keep it well and for your reference

Upright cake showcases

Upright ICE cream showcases

cake showcases

nstallation, Operation & Maintenance Manual

(HC Gas R290 used)

Page 2

Precaution for Use

• The display cases shall be used in proper environment with ambient temp.

<25℃, relative humidity<60%, higher temperature and humidity will

affect cabinet’s running.

• The leakage protection device must be installed and make sure to ground

adequately. Running voltage can be changed within AC 220V±10%,if the

voltage is unstable, choose stabilizer with proper capacity.

• Do not let cabinets close to heat source or under sunshine directly, around

passages and vent shall be closed to avoid damaging air curtain and

affecting refrigeration effect.

• It’s a normal phenomenon that when the cabinet is defrosting, the internal

temperature will rise in a short time.

• The needle type valve si used for system test and refrigerant filling-up, so

do not open it except professional people to prevent refrigerant leakage.

• Do not store inflammable, explosive, volatile fluid or gas.

• The shelves can stand not more tan20kg/m2, or the shelf may be

damaged.

• Put goods in and out carefully, do not throw goods to avoid damaging

cabinets.

• Reserve a certain place when arranging the foods, do not put foods in air

return, or it will affect air flow in cabinet and affect storages effect and

increase the energy consumption.

• Regularly change foods place according to the principle “first in, first out”

to avoid out –of-reach foods overdue or deterioration.

• Clean food scraps timely to avoid block defrosting drainage and lead to ice

clogging.

• Every foods has its shelf life, do not store it indefinitely.

• On the sake of clean, tidy and underlying, the foods shall be provided with

good package.

• Plug-in case has large tonnage, users shall discharge water at times.

• Have circuit inspection for temperature every 2 hours and record it.

Not: The leakage protection device must be tested once a mouth. Ask

professional people to maintain the cabinet if it is not running normally,

Before maintaining it, cut down the power source, also you must wear

security suits and use special tools.

Main Characteristics

•Illumination

There are LEDs in the Cabinet, whose On and Off is controlled if you

need. It can be lighted when dark, also it can be closed when the light

sufficient or in non-business hours to reduce energy consumption. All the

illumination equipment adopt standard parts, so they can be changed if

they fails. Please cut off the power before changing, change it according

Page 3

to maintenance instruction.

•Defrosting

When the display case is frosted, its cooling capacity will degrade, so the

frost shall be removed at intervals. The frequency of defrosting is usually 6

times/24h,with duration of 20min(these settings are only for your

information, the user may ask professional people to make reasonable

according to the exact conditions).It is normal when defrosting, the

temperature will rise and not affect normal use.

•Temperature control

In display case EC-box there has a temperature controller, the user can

change internal temperature by setting temperature controller (let

professional people do it, wrong setting will damage compressor).

•The glass heater(freezer only)

There are glass heaters in the display, whose On and Off is controlled if

you need. It can be removed the fog on the glass, also it can be closed

when the humidity is lower or in non-business hours to reduce energy

consumption.

Daily cleaning and maintenance

The performance and lifespan of the equipment is directly related with

the daily maintenance and cleaning. The regular maintenance of the display

case and its parts and components can lengthen their lifespan and reduce the

cost for use and maintenance.

Page 4

List for maintenance and cleaning (general)

Interva

llocation Content, method and instruction for maintenance and

cleaning

Clean

in

time

Outside

component

s

Use soft cloth with water to rub away water stain, dust,

blot,

rusting, trace of adhesive tape, etc. Neutral detergent

may be

used, if necessary. The yellow stain left by the detergent

shall

be rubbed away with water. Note that the place

around

the food containing salt shall be rubbed at times all

the

more.

Shelf for

goods

Remove the food scrap and other foreign matter in time.

Use

soft cloth with water to rub away water stain and blot.

Not

that every corneal be cleaned to keep off bacteria

Once/

month

Inner

surface

and

attachment

of display

case

Remove the remnant use, food scrap and other foreign

matter

in the case, use soft cloth with water to rub away water

stain,

dust, blot, rusting, use neutral detergent and cleaning

solution

that does not damage the surface of the display case or

pollute

the food to wash the inner surface and attachment, then

use

water to clean.

Lighting

device

Use self-cloth with water to rub away water stain, dust,

blot,

use neutral detergent if necessary, then use dry towel to

clean, dry clean maybe used when dirt is not much.

Note that the power shall be cut off before cleaning.

Water

spout

Clean and remove the dirt deposited at the filtering web

of the

water spout, and use clean water to wash the filtering

web.

Note that the dirt can only be taken out. Flushing

the

dirt into the drainage is not allowed, or it may block

the sewage

Page 5

List for maintenance and cleaning (content)

Interval Location Content, method and instruction for maintenance and

cleaning

Once/1-

3

months

accordi

ng

to real

conditio

ns

Beehive

net at

the air

discharge

Use clean and soft cloth dipped with neutral cleanser

to

clean beehive net surface dirt, then use clean water to

rinse

it, after air-drying, assemble it as before.

Note: if the air-dry not finished, do not run the

cabinet, or the ice scraps will block beehive net

holes.

Plug-in

compressi

ng

rack

Clean compressing rack completely, especially for

compressor, or it will down cabinet refrigerating speed,

decrease refrigerating capacity and increase internal

temperature long time no cleaning will lead to

compressor burned out.

Note: Do not let water on the fan motor, or it will

burned out

Once/2-

4

months

accordi

ng

to real

conditio

ns

Air return

net

Clean out food scraps and residues and remnant ice,

remove

air return net if necessary, special cleaning for those

places

we often omitted.

Note: Scraps and residues are agreed to take out,

not

allowed to rinse into drainage.

Condensin

g fan

Motor

Clean depositions on the condensing fan motor, if

necessary,

remove it to clean, and re-assemble according to the

opposite order. Do not let water on the fan motor.

Note:

Do not use polishing gaskets and agents, or it will damage the surface.

Do not use amino cleansers or corrosive cleansers, or it will damage

parts permanently

Do not let fluid touch e-parts.

Be sure to cut off the power source before cleaning.

Page 6

Daily maintenance and cleaning Guidance for

cleaning and maintenance

•Clean internal surface and evaporator

• Cut off the power source, stop running.

• Take out foods stored in cabinets,and put them in other proper

cases.

• Disassemble bottom bracket, bottom shelf, etc. and clean them.

• Clean bone body: move scraps out the case, then clean. Do not use

water to rinse because of its evaporating system, or dirt will enter

evaporating water box and lead to copper tubes corruption.

• Reassemble all parts in correct order.

• Switch on the cabinet after all parts are drying.

• Start refrigeration function.

• Put foods in the cabinets when its temperature is reasonable.

•Clean water spout

• Discharge the dirt and scraps into prepared water box.

Note: Dirt only allowed to take out, do not let them enter drainage or it

will block drainage.

• Pour proper water to the cabinet, if not flows smoothly, it means the

main water pipe blocked, tell the local maintenance company.

Note: Do not use high-pressure water to rinse the cabinet to

avoid danger.

Installation

• Disassemble wooden package, move the cabinet to the appointed position.

• Check packing list to conform goods.

• For plug-in case, fix L/R Kick plates under L/R side panels.

Maintenance

Preventive maintenance

• Prepare a regular cleaning plan according to the summary of this

instruction, to let employees learn the importance of cleaning and

maintenance and follow the recommended rules. Before cleaning and

checking electrical appliances, switch off the display case, because water

on the parts may cause electrical shock and personal casualty.

• When cleaning display case, clean fan blades and coils, Ensure there has

no dirt and dust on the fan blades and coils exposed, as deposited dirt

Page 7

on the fan blades may cause faults of the motor.

• Check electrical equipment and parts regularly, Find and manage the

small problems in time to avoid serious accident.

• Keep the drainage clean and no scraps or its blockage will degrade

cooling capacity and damage the motors.

• Ammonia or amino detergents can damage electrical parts, so do not

use them.

• Check the adiabatic layer of the suction pipeline and repair its breakage,

to ensure pipeline adiabatic function.

• Make sure the load is appropriate, avoid use large posts in it, do not let

goods block or occupy the air channel. Put goods tidy and clean.

• If there has air flow with opposite direction compare with air curtain, it

will has unbenefited influence on cooling capacity, also too strong

lighting will affect its cooling capacity.

Note: Be sure to cut off the power source, use professional tools and wear

protecting clothes and gloves!

This equipment is intended for the storage and display of

non-potentiallyhazardous packaged products only

Page 8

R290 refrigerant is used for this equipment.

Caution!

Consult repair manual/owner’s guide before attempting to install or service this product.

All safety precautions must be followed. Dispose of properly in accordance with federal or

local regulations. Risk of fire or explosion due to puncture of refrigerant tubing. Follow

handling instructions carefully.

Danger!

Risk of fire or explosion. Flammable refrigerant used. To be repaired only by trained

service personnel. Do not use mechanical devices to defrost refrigerator. Do not puncture

refrigerant tubing.

Disposal

EU regulations require refrigeration product to be disposed of by specialist

companies who remove or recycle all gasses,

metal and plastic components.

Consult your local waste collection authority regarding disposal of your

appliance. Local authorities are not obliged to

dispose of commercial refrigeration equipment but may be able to offer advice on how to

dispose of the equipment locally.

All packaging materials should be disposed of in an environmentally friendly way.

The cardboard may be used as scrap paper. The protective foil and the

foam cushions are CFC-free.

Do not allow children to play with the packaging and destroy plastic bags

safely.

Environmental protection

Discarded electric appliances are recyclable and should not be discarded

Page 9

in the domestic waste! Please actively support us in conserving resources and protecting

the environment by returning this appliance to the collection centers (if available).

Compliance

Parts have undergone strict product testing in order to comply with regulatory standards

and specification set by

international, independent, and federal authorities.

Products have been approved to carry the following symbol:

Table of contents