OriginalInstructions [EN]

d) Pushthesawthroughtheworkpiece.Donotpullthesawthroughtheworkpiece.To

makeacut,raisethesawheadandpullitoutovertheworkpiecewithoutcutting,startthe

motor,pressthesawheaddownandpushthesawthroughtheworkpiece. Cuttingonthe

pullstrokeislikelytocausethesawbladetoclimbontopoftheworkpieceandviolentlythrowthe

bladeassemblytowardstheoperator.(onlyforslidesaw)

e) Nevercrossyourhandovertheintendedlineofcuttingeitherinfrontorbehindthesaw

blade. Supportingtheworkpiece crosshanded”i.e.holdingtheworkpiecetotherightofthesaw

bladewithyourlefthandorviceversaisverydangerous.

f)Donotreachbehindthefencewitheitherhandcloserthan100mmfromeithersideofthe

sawblade,toremovewoodscraps,orforanyotherreasonwhilethebladeisspinning. The

proximityofthespinningsawbladetoyourhandmaynotbeobviousandyoumaybeseriously

injured.

g) Inspectyourworkpiecebeforecutting.Iftheworkpieceisbowedorwarped,clampitwith

theoutsidebowedfacetowardthefence.Alwaysmakecertainthatthereisnogapbetween

theworkpiece,fenceandtablealongthelineofthecut. Bentorwarpedworkpiecescantwist

orshiftandmaycausebindingonthespinningsawbladewhilecutting.Thereshouldbenonails

orforeignobjectsintheworkpiece.

h) Donotusethesawuntilthetableisclearofalltools,woodscraps,etc.,exceptforthe

workpiece. Smalldebrisorloosepiecesofwoodorotherobjectsthatcontacttherevolvingblade

canbethrownwithhighspeed.

i) Cutonlyoneworkpieceatatime. Stackedmultipleworkpiecescannotbeadequatelyclamped

orbracedandmaybindonthebladeorshiftduringcutting.

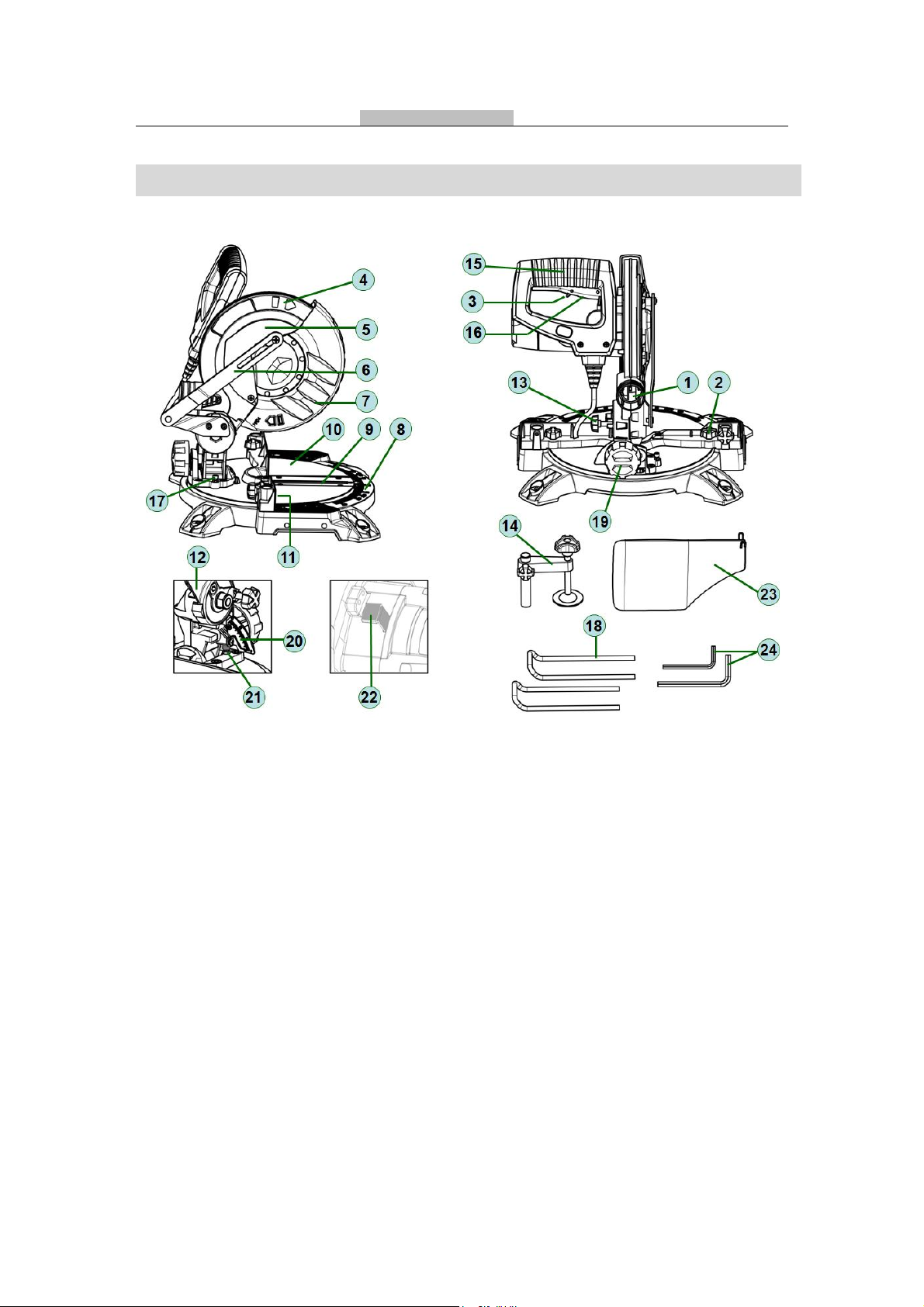

j) Ensurethemitresawismountedorplacedonalevel,firmworksurfacebeforeuse. A

levelandfirmworksurfacereducestheriskofthemitresawbecomingunstable.

k) Planyourwork.Everytimeyouchangethebevelormitreanglesetting,makesurethe

adjustablefenceissetcorrectlytosupporttheworkpieceandwillnotinterferewiththe

bladeortheguardingsystem. Withoutturningthetool ²ON²andwithnoworkpieceonthetable,

movethesawbladethroughacompletesimulatedcuttoassuretherewillbenointerferenceor

dangerofcuttingthefence.

l) Provideadequatesupportsuchastableextensions,sawhorses,etc.foraworkpiecethat

iswiderorlongerthanthetabletop. Workpieceslongerorwiderthanthemitresawtablecan

tipifnotsecurelysupported.Ifthecut-offpieceorworkpiecetips,itcanliftthelowerguardorbe

thrownbythespinningblade.

m)Donotuseanotherpersonasasubstituteforatableextensionorasadditionalsupport.

Unstablesupportfortheworkpiececancausethebladetobindortheworkpiecetoshiftduringthe

cuttingoperationpullingyouandthehelperintothespinningblade.

n) Thecut-offpiecemustnotbejammedorpressedbyanymeansagainstthespinningsaw

blade. Ifconfined,i.e.usinglengthstops,thecut-offpiececouldgetwedgedagainstthebladeand

thrownviolently.

o) Alwaysuseaclamporafixturedesignedtoproperlysupportroundmaterialsuchas

rodsortubing. Rodshaveatendencytorollwhilebeingcut,causingthebladeto ²bite²andpull

theworkwithyourhandintotheblade.

p) Letthebladereachfullspeedbeforecontactingtheworkpiece. Thiswillreducetheriskof

theworkpiecebeingthrown.

q) Iftheworkpieceorbladebecomesjammed,turnthemitresawoff.Waitforallmoving

partstostopanddisconnecttheplugfromthepowersourceand/orremovethebattery

pack.Thenworktofreethejammedmaterial. Continuedsawingwithajammedworkpiece

couldcauselossofcontrolordamagetothe.mitresaw.

r) Afterfinishingthecut,releasetheswitch,holdthesawheaddownandwaitfortheblade