HOTSTREAM TAPWARE - OPEN VENTED HOTSTREAM Installation Instructions

1. ELECTRICAL REQUIREMENTS

• This appliance must be earthed.

• Cold water resistivity rating 1300 Ohm.cm at 15°C.

• This appliance must be wired and connected by a registered

electrician in accordance with local wiring regulations.

WARNING: A supply isolation switch MUST be tted.

• Electrician to check for cable size to prevent voltage drop.

• Using the hot tap, air must be bled from heater before electrical

power is switched on.

•This is an open outlet appliance. Pressure rating 0 pa.

ONLY HOTSTREAM TAPS AND FITTINGS MUST BE USED

2. PLUMBING REQUIREMENTS

1. Minimum water pressure: 240 kPa (35psi)

Maximum water pressure: 517 kPa (72psi)

2. All units must be installed by a registered Plumber.

3. The Hotstream heater is an open outlet appliance. The

outlet acts as a vent and must always remain open to the

atmosphere. For this reason, only Hotstream taps and

fittings must be used.

4. All air must be bled from heater and pipes by turning

on the hot tap and letting run for 5 minutes BEFORE

the electricity is switched on. This procedure must be

followed whenever the water supply is interrupted, turned

off or whenever there is a risk of air pockets being present

in the water supply. In areas prone to air locks in the water

supply, an air eliminator valve should be fitted.

5. In New Zealand: an insolating stop-cock must be fitted

to the cold water supply for all models.

6. Take care during installation of heaters. Unnecessary force

can result in breakage.

7. For multiple installations where all units are likely to be

in operation at the same time (e.g. bank of showers,

washrooms, hairdressing salons etc) it is CRITICAL that

the plumbing allows for sufcient water ow, regardless

of pressure. In general, the diameter of the cold water

pipe must increase proportionately as the number of units

increases, in order to compensate for pressure drops when

all units are operating. As an example, for a bank of 8 units,

a 1½” feed pipe would generally be required rather than a

½” pipe, depending upon pressure.

8. We recommend tting a 350 kPa pressure limiting valve

to all installations where the incoming pressure exceeds

500 kPa.

WARNING: Water heater must not be switched on if there is a possibility that the water in the heater is frozen.

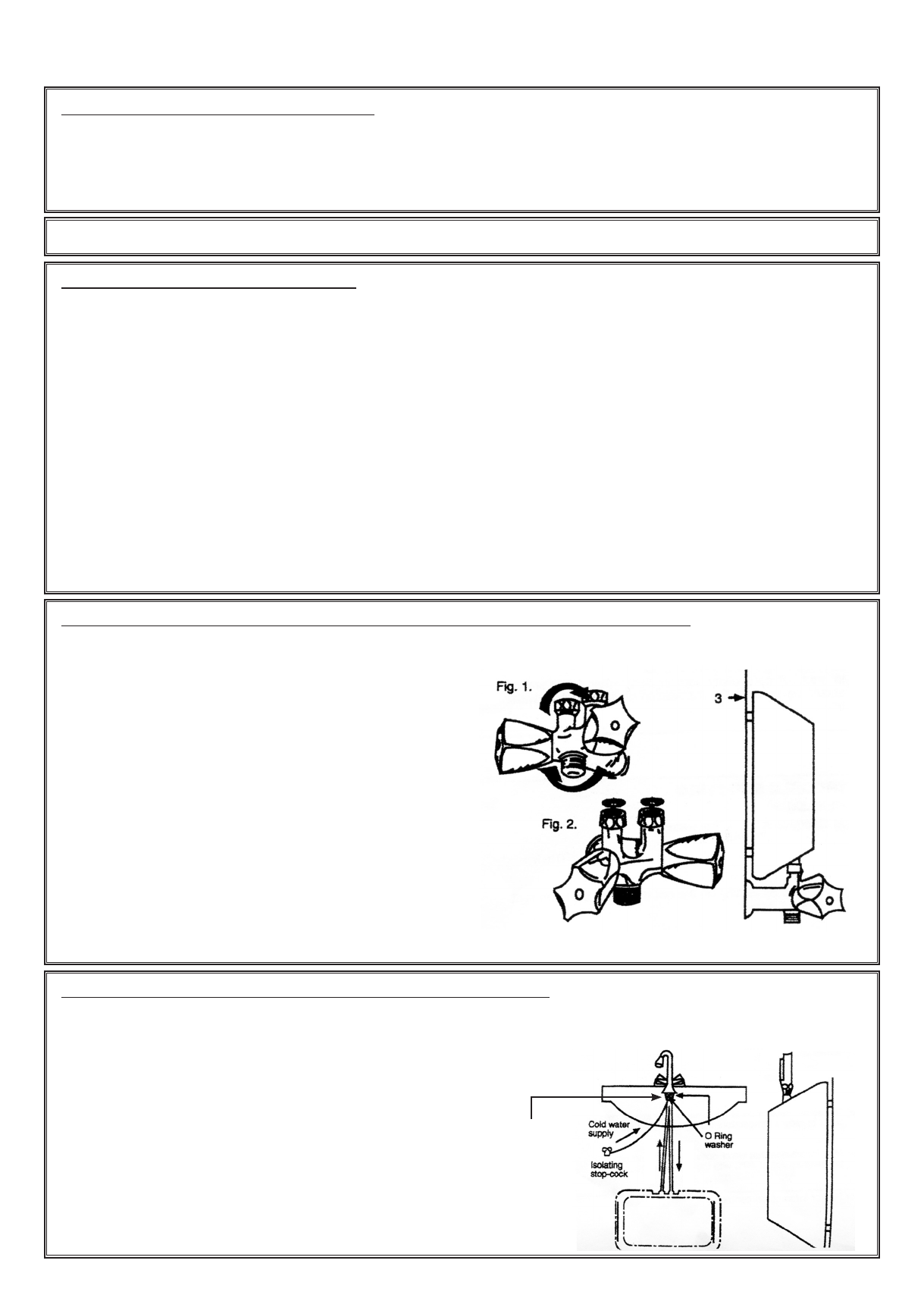

3. FOR HEATERS INSTALLED ABOVE THE BASIN OR IN SHOWERS

1. For new installations one ½”/15mm BSP female threaded

cold water supply socket is required.

2. Screw the mixing tap into the water main nishing in a

horizontal position as illustrated in Fig. 1.

3. Temporarily mount heater unit minus front cover. Ensure

distance of mixing tap from wall surface is compatible

with distance required to attach the unit directly a at wall

surface. If this is not possible - see attachment.

4. Place the supplied washer in to each connecting nut and

mount the heater into position. When tightening hexagonal

nuts on mixer do not apply excessive force.

5. Turn on the water mains supply.

6. Bleed all air from heater and pipes by turning on

the HOT tap and let run for 5 minutes BEFORE the

electricity is switched on.

7. A packer may be necessary to allow the unit to be screwed

back with even pressure, with no excess pressure on the

heater unit (NB: excess pressure on the back mounting

cover will cause the unit to leak.

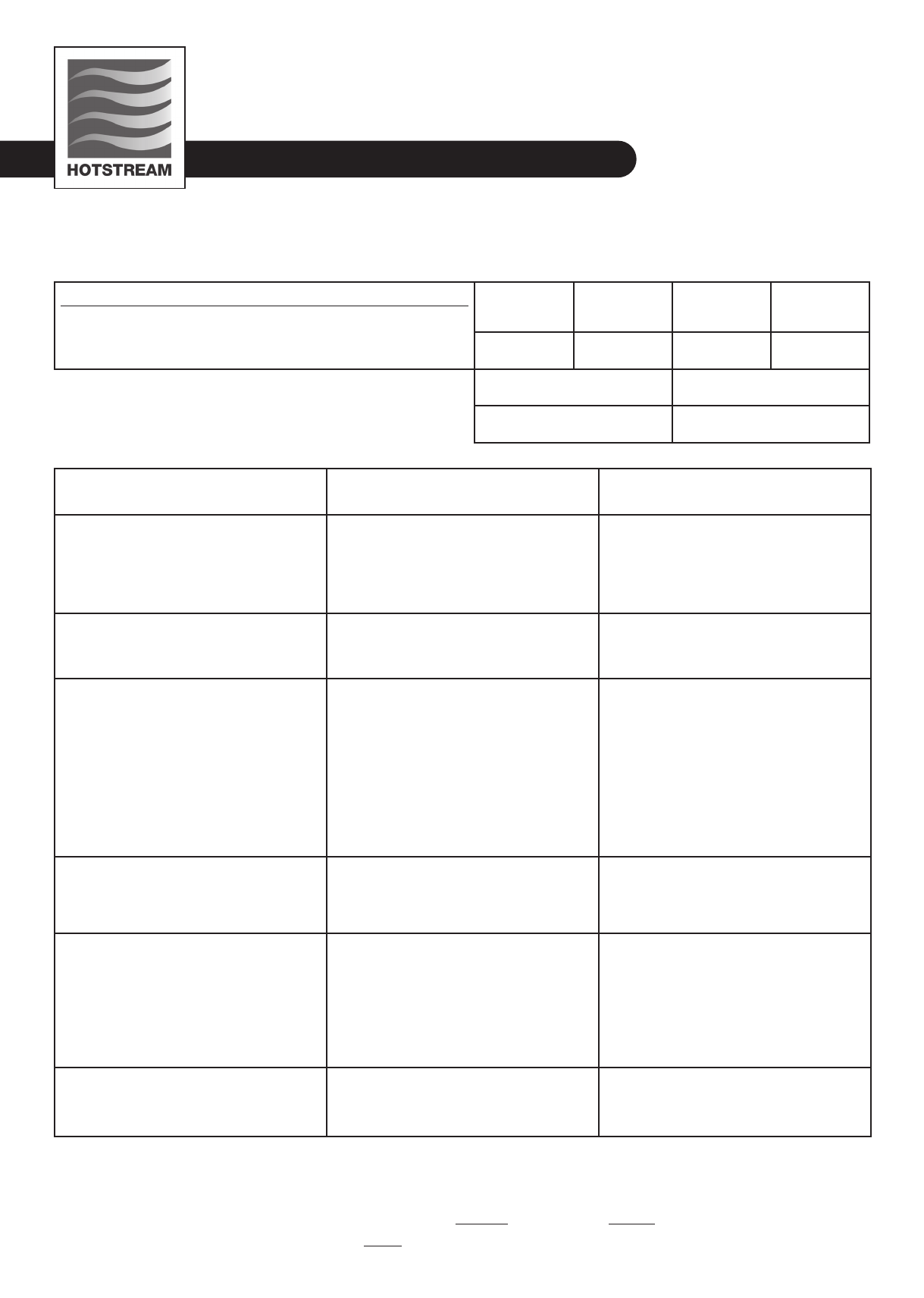

4. FOR HEATERS INSTALLED BENEATH THE BASIN

1. Fix the three-way combination tap securely to the hand

basin or kitchen bench, ensuring that the sealing washers

supplied are tted correctly.

2. Turn off the water mains supply and close both taps of the

mixer.

3. Connect the short pipe to the cold water mains control tap.

4. Connect the long pipe (with the blue arrow pointing

downwards) to the inlet side of the heater as shown by

the arrow on the heater. (This is the cold water supply to

the heater).

5. Connect the pipe with the red arrow to the outlet of the

heater. Do not forget the washers.

6. Turn on the water mains supply.

7. Bleed all air from the heater and pipes by turning

on HOT tap and let run for 5 minutes BEFORE the

electricity is switched on.

Hot inlet

Cold inlet

O Ring

Right to left