Code Operating mode Description

REC Recirculation

On/Off recirculation operation with TempTronic algorithm: During heat

or cool demand, the unit draws in room air, heats or cools it and blows it

back into the room. The room temperature set value day is active. The

ow rate is controlled in 2 stages.

Supply air fan................... 0 / Speed 1 / Speed 2 *)

Exhaust air fan................. off

Energy recovery............... 0 %

Extract air damper............ closed

Recirculation damper ....... open

Heating/cooling ................ on *)

*) Depending on heat or cool demand

EA Exhaust air

The unit extracts spent room air. There is no room temperature control.

Unltered fresh air enters the room through open windows and doors or

another system provides air supply.

Supply air fan................... Off

Exhaust air fan................. on *)

Energy recovery............... 0 %

Extract air damper............ open

Recirculation damper ....... closed

Heating/cooling ................ off

*) Adjustable ow rate

SA Supply air

The unit blows fresh air into the room. The room temperature set value

day is active. Depending on the temperature conditions, the system

controls the heating/cooling.

Spent room air passes through open windows and doors or another

system provides extraction.

Supply air fan................... on *)

Exhaust air fan................. off

Energy recovery............... 0 % **)

Extract air damper............ open

Recirculation damper ....... closed

Heating/cooling ................ 0-100 %

*) Adjustable ow rate

**) Fresh air and bypass dampers are open

ST Standby

The unit is normally switched off.

The following functions remain active:

CPR

■ Cooling protection:

If the room temperature drops below the set value for cooling protec-

tion, the unit heats up the room in recirculation operation.

Supply air fan................... MAX

Exhaust air fan................. off

Energy recovery............... 0 %

Extract air damper............ closed

Recirculation damper ....... open

Heating/cooling ................ on

OPR

■ Overheating protection:

If the room temperature rises above the set value for overheating

protection, the unit cools down the room in recirculation operation. If

the temperatures also permit fresh air cooling, the units automatically

switches to night cooling (NCS) to save energy.

NCS

■ Night cooling:

If the room temperature exceeds the set value for night cooling and

the current fresh air temperature permits it, the unit blows cool fresh air

into the room and extracts warmer room air.

Supply air fan................... on *)

Exhaust air fan................. on *)

Energy recovery............... 0 %

Extract air damper............ open

Recirculation damper ....... closed

Heating/cooling ................ off

*) Adjustable ow rate

L_OFF Off (local operating mode)

The unit is switched off. Frost protection remains active.

Supply air fan................... Off

Exhaust air fan................. off

Energy recovery............... 0 %

Extract air damper............ closed

Recirculation damper ....... open

Heating/cooling ................ off

– Forced heating

The unit draws in room air, warms it and blows it back into the room.

Forced heating is activated by inserting a wire jumper in the control

block. For example, it is suitable for heating the hall before taking the

control system into operation or if the controller fails during the heating

period. Connecting a room thermostat makes it possible to specify a room

temperature set value.

Supply air fan................... MAX

Exhaust air fan................. off

Energy recovery............... 0 %

Extract air damper............ closed

Recirculation damper ....... open

Heating ............................ on

Table 1: Operating modes of the RoofVent®units

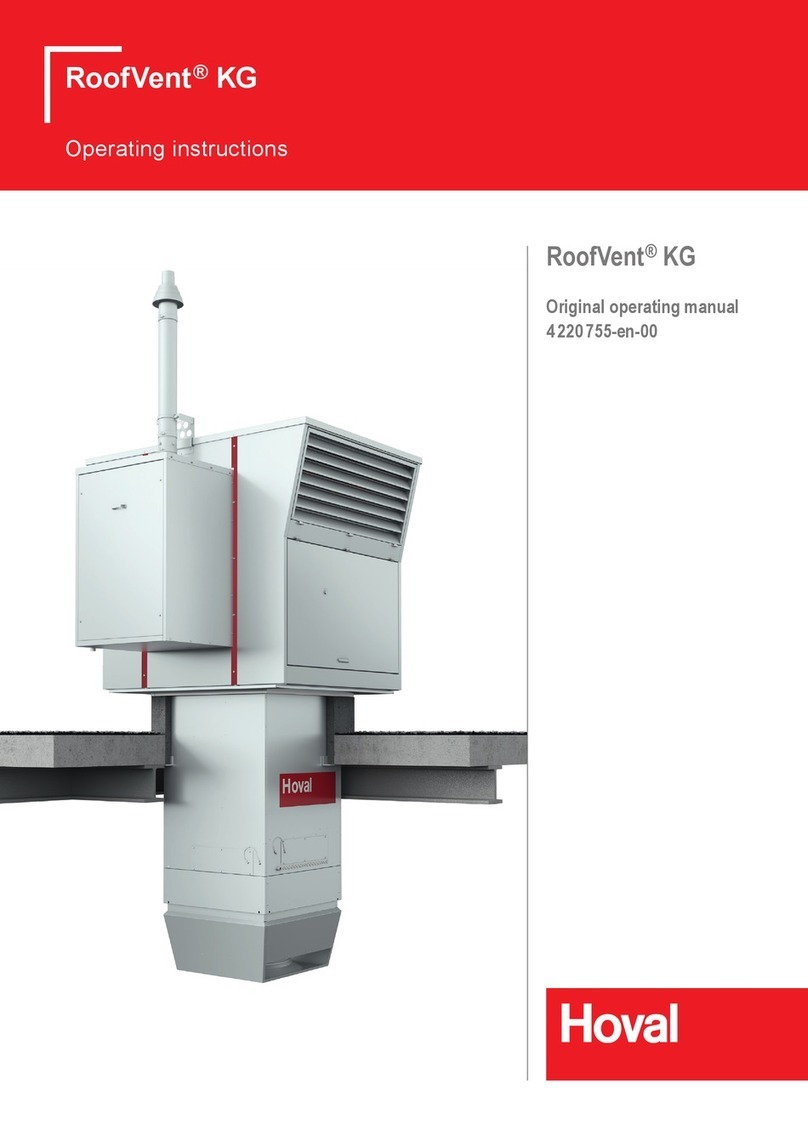

RoofVent®RH |RC |RHC |R

Construction and operation

Art.No. 4 214 745-en-04 / Page 9