HP 8340B/41B Assembly-Level

Service Introduction

CONTENTS

INTRODUCTION .............................................................. A-1

Manual Format .................................................. ............ A-1

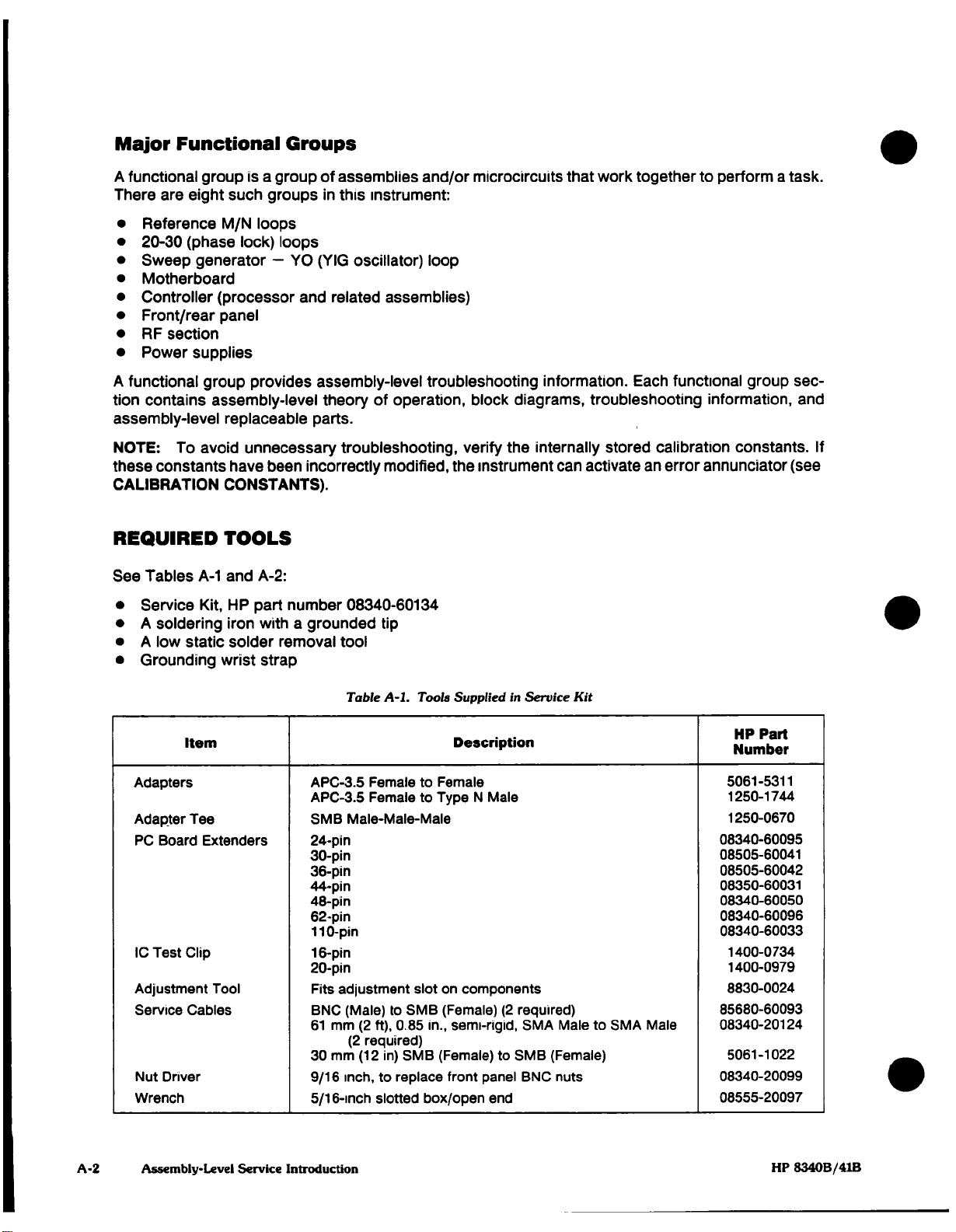

Required Tools .............................................................. A-2

Interconnect Cables and Mnemonics ............................................. A-3

OVERALL INSTRUMENT THEORY ............................................. A-4-

Reference Loops ............................................................. A-4

M/N Loop ................................................................... A-4

20-30 Loops ................................................................. A-5

YO Loop .................................................................... A-5

Controller Section ............................................................ A-5

Front Panel-Rear Panel ........................................................ A-6

RF Section .................................................................. A-6

Power Supplies .............................................................. A-7

HP 8340B/41B Block Diagram .................................................. A-9

CALIBRATION CONSTANTS .................................................. A-11

Instrument Access ........................................................... A-11

User Access ................................................................ A-13

Calibration Constants Description .............................................. A-16

How to Restore Factory-Optimized Calibration Constants ........................... A-23

TROUBLESHOOTING AIDS ................................................... A-25

Self Test ................................................................... A-25

Phase-Lock Indication LEDs ................................................... A-25

Power Supply Indication LEDs ................................................. A-25

FRONT PANEL DIAGNOSTICS ................................................ A-26

Shift Manual ................................................................ A-27

Shift Free Run ........................................................... A-27

Shift Ext ................................................................... A-27

Shift M1 ................................................................... A-28

Shift M2 .................................................................. A-28

Shift M3 ................................................................... A-28

Shift M4 ................................................................... A-29

Shift M5 ................................................................ ,. A-29

Shift RF .................................................................. A-29

Shift Meter ................................................................ A-29

Shift Peak ............................................................... A-30

Shift Pwr Sweep ............................................................ A-30

Shift Slope ................................................................. A-30

HP 8340B/41B Table of Contents