Never manoeuvre the Pop-Up whilst in its elevated

position, as this may cause instability.

Never enter or exit the platform unless the platform is in

the lowered and transport position.

Never apply external side loads to the platform or

scissor structure.

Never allow persons at ground level to operate the

controls whilst the platform is occupied (unless in an

emergency situation).

For advice on the safety and suitability of this

equipment contact your local HSS Hire.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed prior

to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment is designed to be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using cones and

either barriers or tape, available for hire from your local

HSS Hire.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or

drugs.

Wear practical, protective clothing,

gloves, footwear and a protective hard

hat. Avoid loose garments and jewellery that could catch in

moving parts, tie back long hair.

Do not work near flammable gases or liquids, petrol or

paint thinner fumes for example. Keep combustible

materials at a safe distance – at least 5m.

Make sure you know how to switch this equipment OFF

before you switch it ON in case you get into difficulty.

Make sure you know how to operate this equipment

safely and are aware of its limitations before you use it.

Make sure that everyone is warned of what you are

doing.

This machine is designed for internal use only. If working

in a building which has large openings where wind gusts

occur, DO NOT USE THE MACHINE.

The maximum number of occupants must not exceed

one.

Never use the lift near overhead power lines or similar

hazards.

Never exceed the equipment’s safe working load of

240Kg.

Never operate the equipment alone. Ensure a competent

adult is always within shouting range to operate the

manual descent system or come to your aid if anything

should go wrong.

Never use the platform as a goods lift or crane.

Never try to move the platform on its castors when

elevated.

Never extend the height of the platform by using boxes,

steps ladders etc.

Never modify the Pop Up Access Platform in any way

without the full approval of the manufacturer.

Never manoeuvre the platform on an inclined surface

otherwise it may become uncontrollable.

GENERAL SAFETY

ELECTRICAL SAFETY

GETTING STARTED

IDENTIFIER

WARNING

THIS MACHINE HAS NOT BEEN

DESIGNED FOR OPERATION WITHIN

POTENTIALLY EXPLOSIVE ATMOSPHERES

The Pop Up Access Platform is a scissor lift type work

platform, which is manoeuvred manually into work

positions and elevated and lowered using an electro-

hydraulic control system.

Pop Up Access Platform must not be used in

applications or for uses outside of the scope of this

operating safety guide. Should a certain application not

be covered, then your local HSS should be contacted.

This guide provides information on the safe operation

of Pop Up Access Platform. Operators should read and

understand all of the information contained within this

manual prior to operating the platform.

This machine has been tested for Electromagnetic

Compatibility (EMC) however, operation near to high

BASIC TECHNIQUES

Select a site for the machine from which the platform will

be able to reach the required work area. A visual

inspection of the operating site should be made before

setting up the machine.

Ensure that the ground on which the Pop Up is to

operate is capable of supporting the weight of the

machine (including the weight of the operator plus tools

and materials). Be aware of floors or coverings (e.g.

manhole covers) that may not withstand point loadings

exerted by the castor wheels.

The platform must only be operated on flat (0º chassis

inclination) and level surfaces. The allowable chassis

inclination is indicated when the bubble spirit evel is within

the marked limits. All castor wheels must be in full

contact with the ground.

Ensure that adequate clearance is available above and

around the platform before elevation.

Training card

Guard rail Gate

Platform

Main

lift cylinder

Control pendant

Emergency

stop button

& key

Maintenance

Isolator

switch

Bubble

spirit

level

Chassis

Warning

buzzer

Emergency

lowering

valve

WARNING

THIS MACHINE IS NOT ELECTRICALLY INSULATED

AND MUST NEVER BE USED FOR LIVE LINE

WORKING. DEATH OR SERIOUS INJURY CAN

RESULT FROM CONTACT WITH, OR INADEQUATE

CLEARANCE FROM, ELECTRICAL CONDUCTORS

FIRE WARNING

BATTERIES GENERATE HIGHLY FLAMMABLE AND

POTENTIALLY EXPLOSIVE HYDROGEN GAS WHEN

CHARGING, SO, UNTIL CHARGING IS OVER AND THE

GAS HAS DISPERSED...

ALWAYS STAND THE LIFT IN A WELL-VENTILATED

SPOT, PREFERABLY IN THE OPEN AIR.

ALWAYS OPEN THE BATTERY COMPARTMENT COVER.

NEVER SMOKE OR ALLOW NAKED LIGHTS AND

OTHER IGNITION SOURCES INTO THE AREA.

powered radio transmission apparatus (e.g. radar,

antennae) or within strong electrical and/or magnetic

fields may affect some features of this product.

Before operating platform familiarise yourself with the

work area, check for possible hazards such as potholes,

ramps, slopes and overhead obstructions that could

affect the safe use of the equipment.

Operating procedures should be preceded with pre-

operation checks (see Pre-operation checklist).

If checks reveal malfunctions or damage on the Pop Up

Access Platform, then the machine must not be used

until the problem is rectified.

If in doubt, seek further assistance from your local HSS

Hire.

If safety decals are no longer legible or missing, please

also contact HSS Hire.

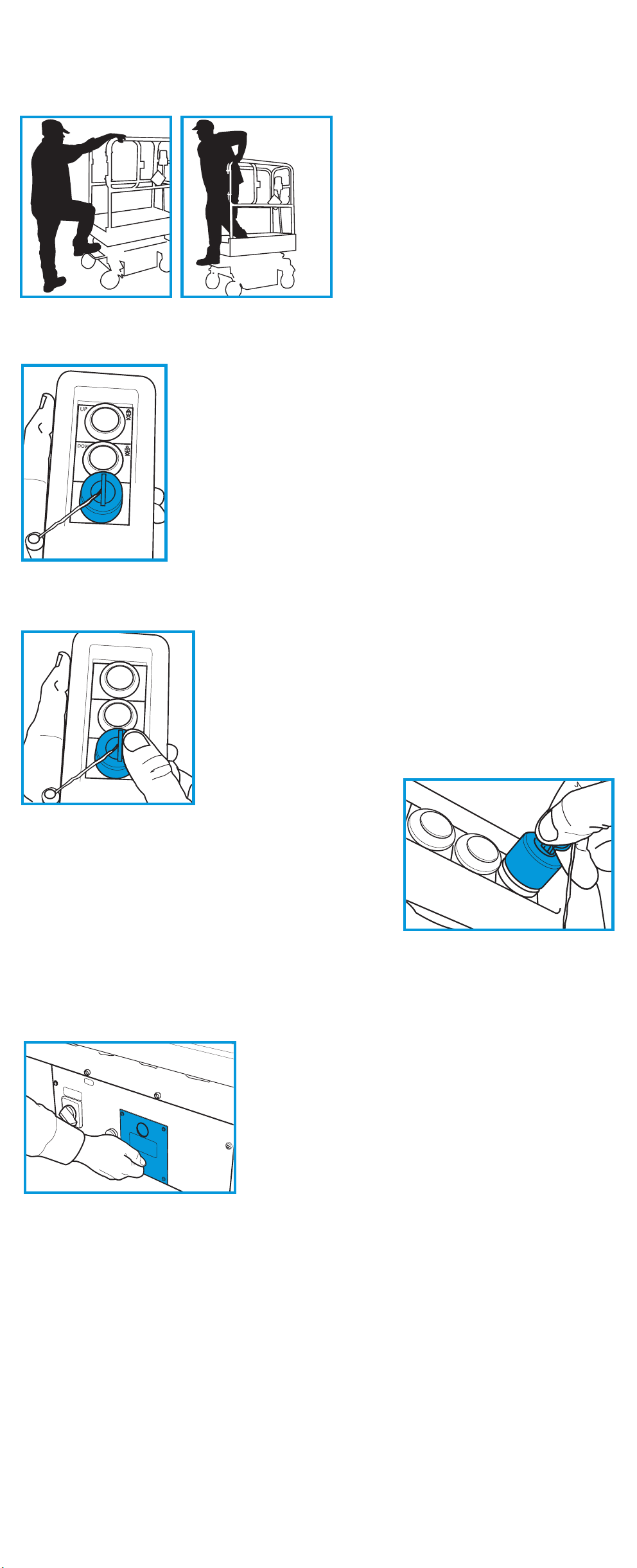

ENGAGING THE BRAKES

Always ensure that both castor brakes are locked before

elevating the work platform to prevent any inadvertent

movement.

The brakes are

engaged by

pushing down

on the lever and

pulling up the

lever as shown.

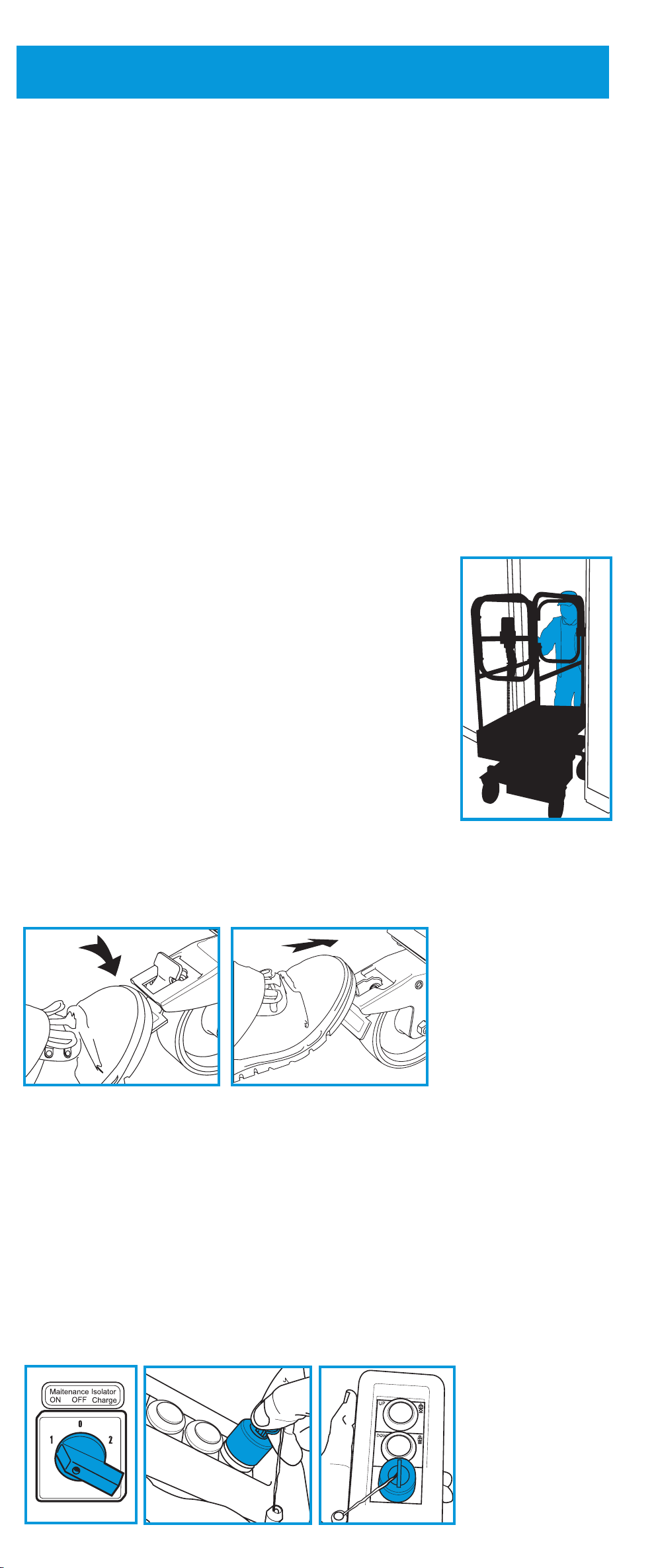

MANOEUVRING THE PLATFORM

Manoeuvre the platform into position

using both hands on the guard rails at

gate end. Take care to avoid trapping

hands or feet whilst manoeuvring the

platform.

Never manoeuvre the Pop Up whilst it is

elevated or with a person, tools or

materials in the platform.

POWERING UP

The Pop Up Access Platform is provided with a key operated

switch which is used to isolate the battery and therefore the

electrical system, preventing unauthorised use.

To enable the electrical system, first turn the Maintenance

Isolater switch to position‘1’ (ON) and insert the key into the

emergency stop button. Turn clockwise to release the

button. Ensure that when the machine is not in use, the

emergency stop button is depressed and the key is removed.

Turn the

Maintenance

Isolator switch

to position ‘0’

(OFF).

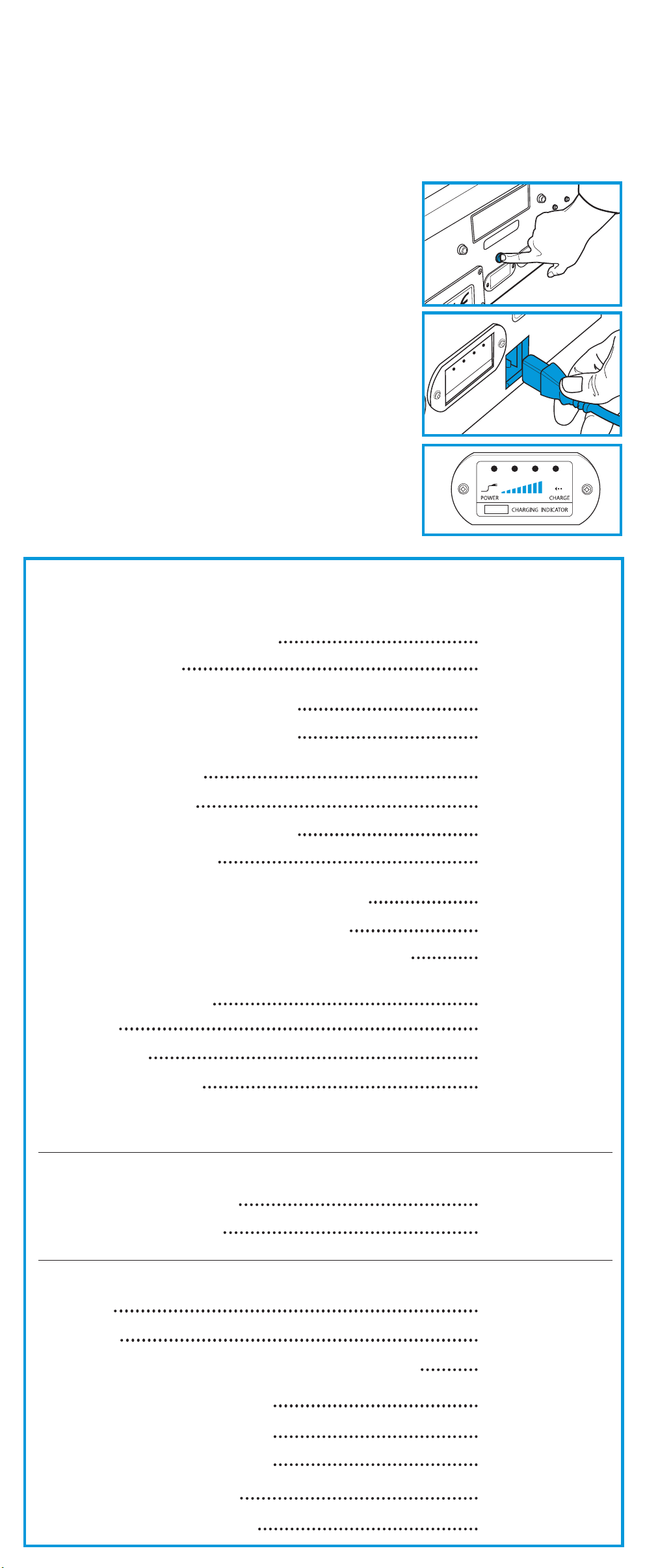

The Pop Up Access Platform is powered by 12v DC

batteries. Always fully charge before use and recharge

at regular intervals.

Never operate the lift when charging the battery.

After charging, switch OFF the power supply and

disconnect the power supply lead from the charger. If

the charger fails, or its power supply cable or lead becomes

damaged, return the unit. Do not attempt to repair

anything yourself.

Keep the charger dry at all times. Using electrical

equipment in wet or damp conditions can be

dangerous.

To reduce the risk of electric shock, always use a

suitable RCD (Residual Current-Operated Device)

available from your local HSS Hire.

Hydraulic tank Hydraulic Pack

Battery

Battery charger

Battery

charging

indicator

Battery

charger

socket

Battery

condition meter

& button

Chassis plate

UP button

DOWN button

Winch point

Castor break

Maintenance

props

Maintenance

Isolator

switch Warning

buzzer

Emergency

lowering valve

MODEL 1

MODEL 2

Key

switch