9

1. Use und Feature

1,1 Use

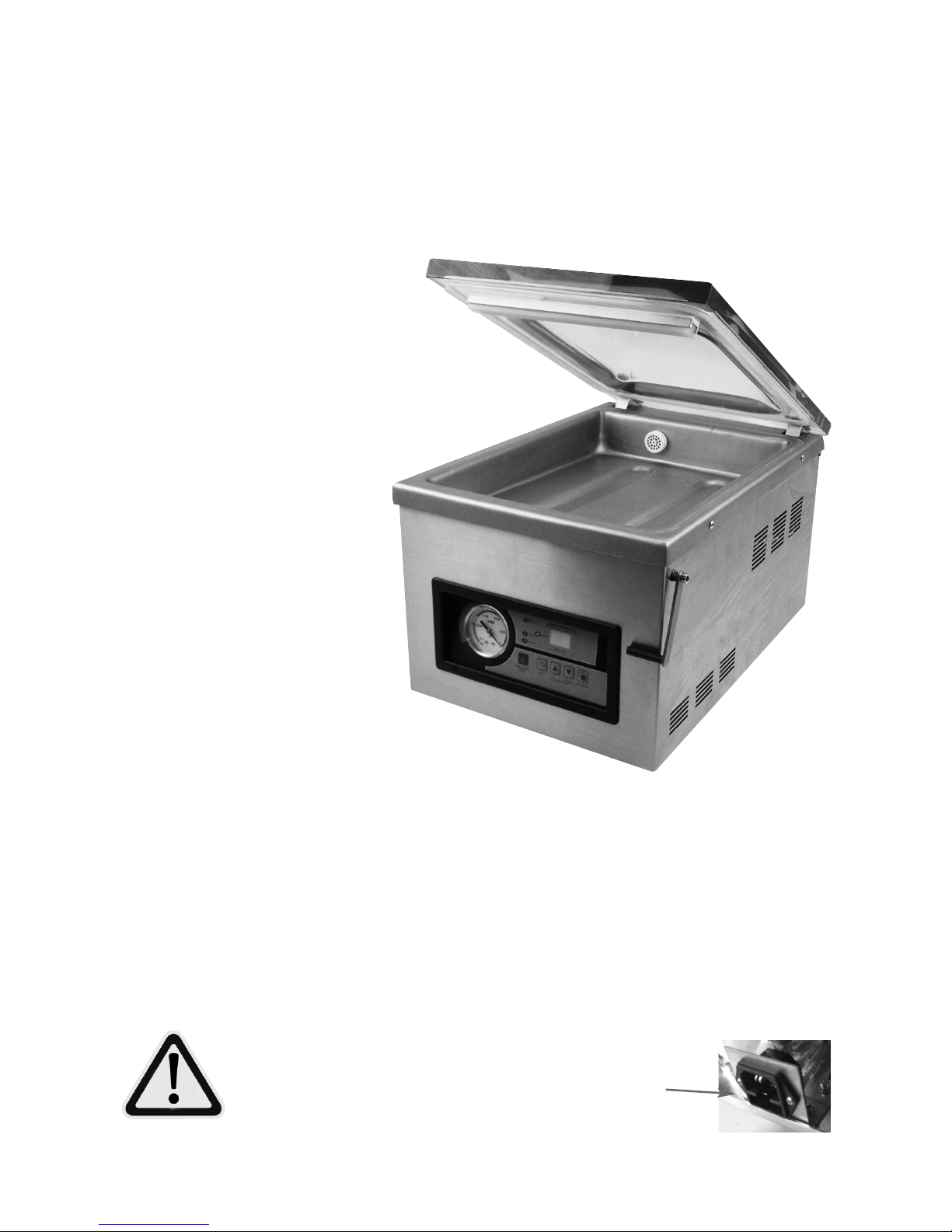

DZ 260-PD series vacuum packaging machine possesses the advantages of su-

perior function, easy operation, simple maintenance, wide application etc. It ap-

plies to the soft packing material such as composite film or aluminium-plastic

composite film and so on. It can pack grain, food, fruit, seed, medicine, chemica

product, elektronic product, precision instrument and meter, rare expensive metal

solid etc in liquid, powder or paste shape. The products after packing can be pre-

vented from oxidization, mildew, moth, rot and damp, so quality and freshness is

guaranteed to prolong the food`s period.

1,2 Feature

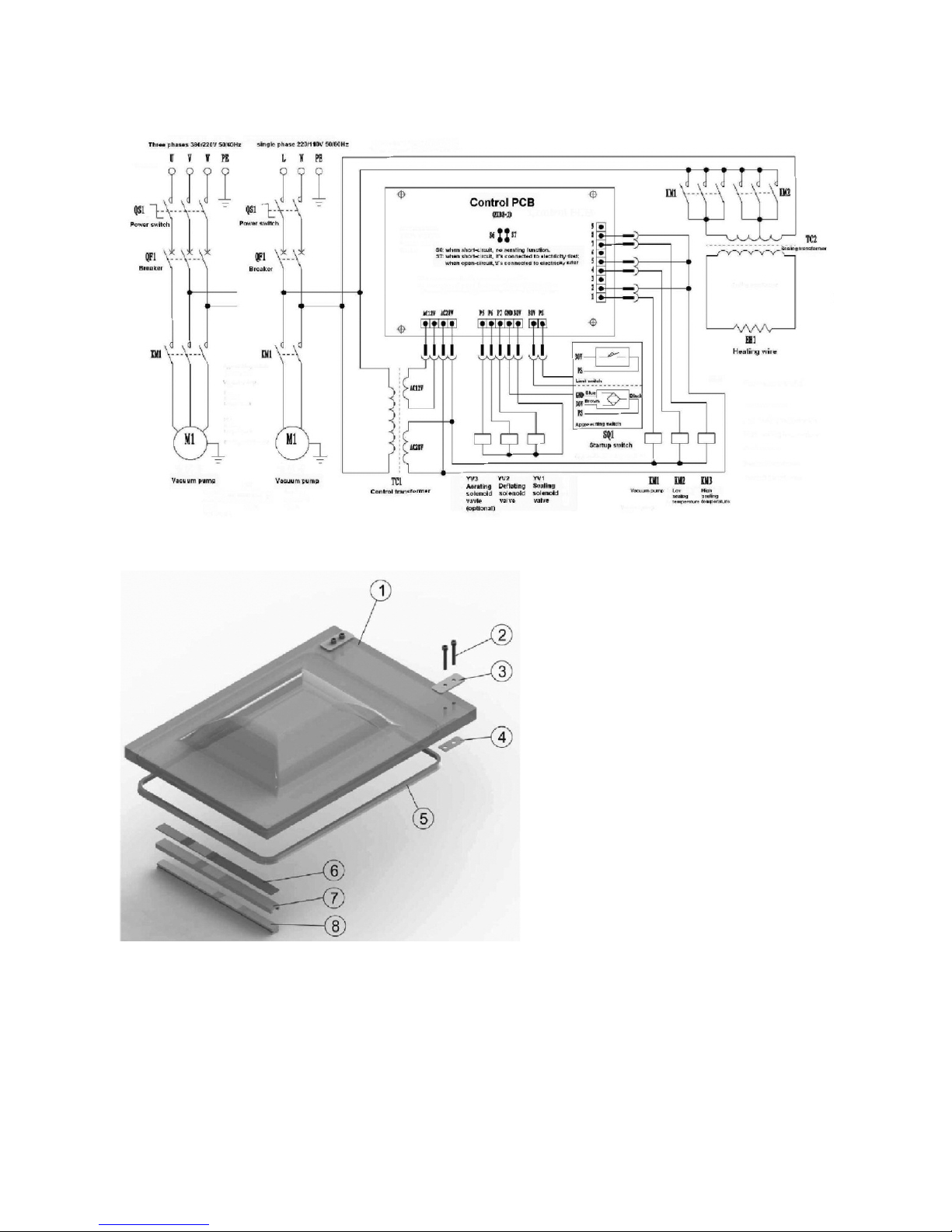

1,2,1 This machine is easy to use. The whole process, including pressing va-

cuum lid to suck air out of pouch, sealing, label printing, cooling, vacuum

devac, vacuum lid-opening, is automatically controlled by programm.

1,2,2 Adopt built-in power line for sealing, the circuit is safe anf reliable without

any power lead inside vacuum chamber. It`s easy to replace seal wire.

1,2,3 The regulating range of sealing temperature and time are very wide so that

the machine is suitable for packing various pouches in different materials

and thickness.

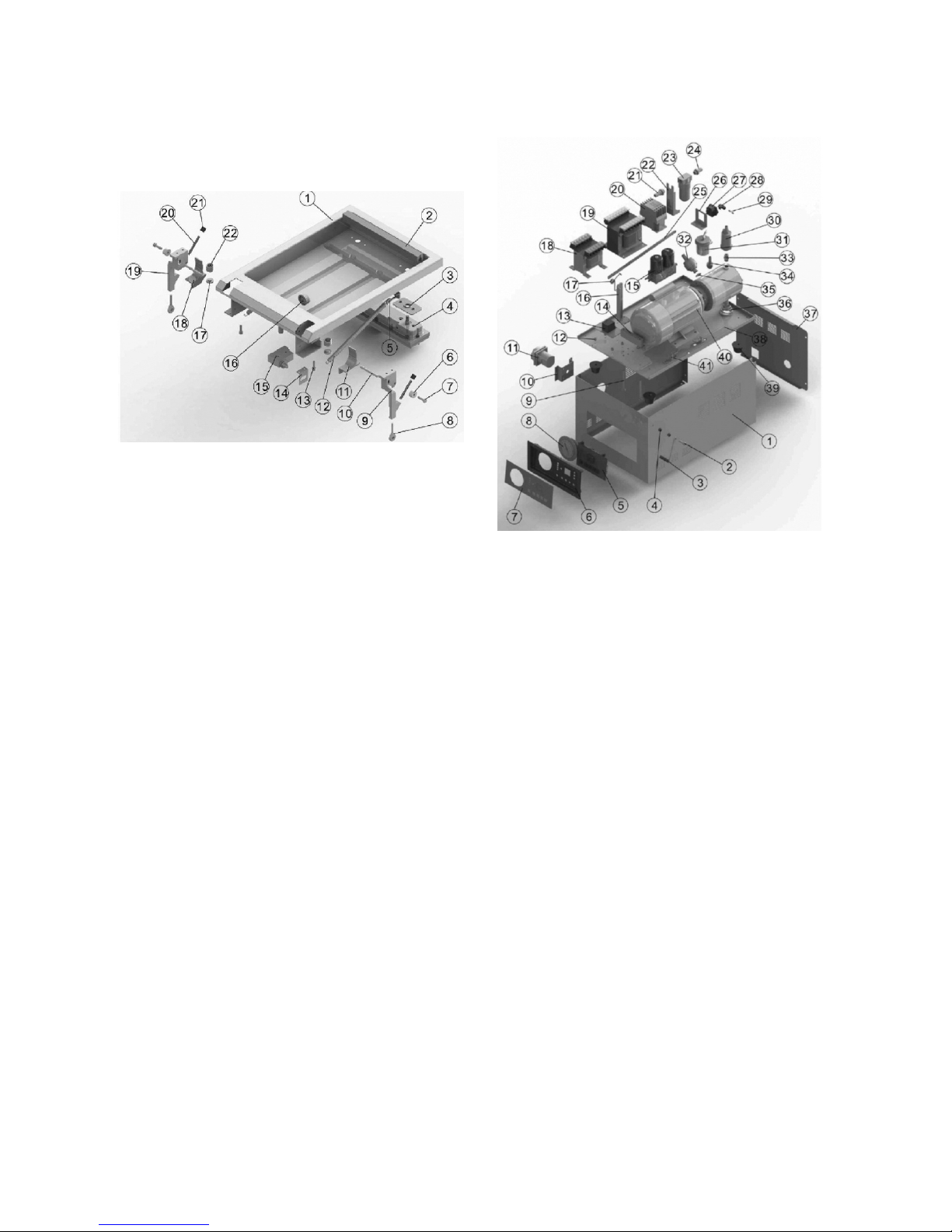

1,2,4 There is an emergency stop button on control panel. If any abnormal

phenomenon occurs to the product during vacuum cycle, press the

emergency stop button to stop the packing procedure.

2. Model & Specification

Model: XD08

Voltage: 220V/50Hz, 110V/60Hz

Motor Power: 370W

Vacuum Chamber Size ( xH): 370x255 mm

Sealing Size ( xW): 260x5 mm

Sealing Type: Single Sealing

Pump Rate: 8 m3/h

Chamber Dimensions ( xWxH): 282x385x100 mm

External Dimension ( xWxH): 360x488x305 mm

Net Weight (Kg): 41 kg