1

1Product Overview

Materials

Delivered with

the Equipment

Cord end terminal (10 mm2) for the indoor unit power cable, OT ground

terminal (10 mm2) for the indoor unit power cable, cable tie, hexagon bolt

assembly (M12x45), and four M6x16 bolts

Engineering

Purchasing

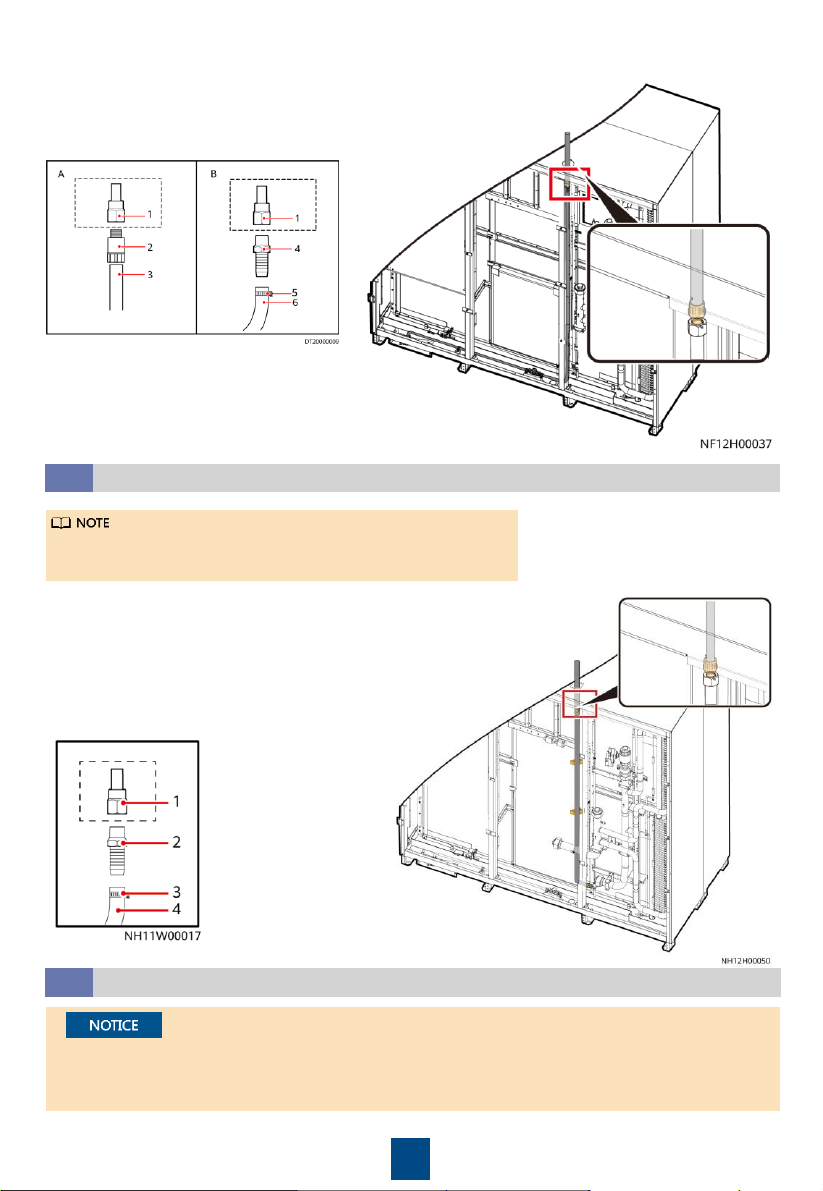

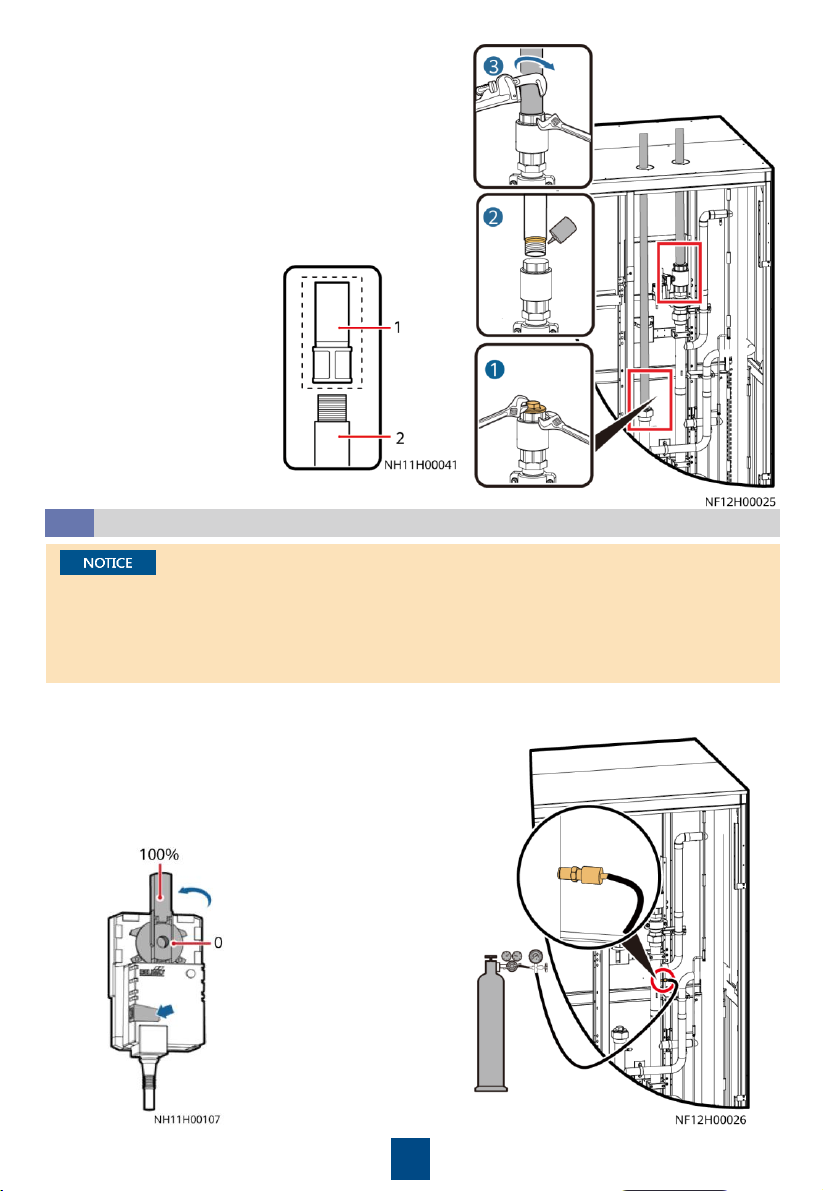

Drainpipe G 1/2 inch outer screw thread

Water inlet/outlet pipe DN50 seamless steel pipe with a G 2 inch external

threaded connector

Water inlet pipe for the

wet film humidifier G 1/2 inch outer screw thread

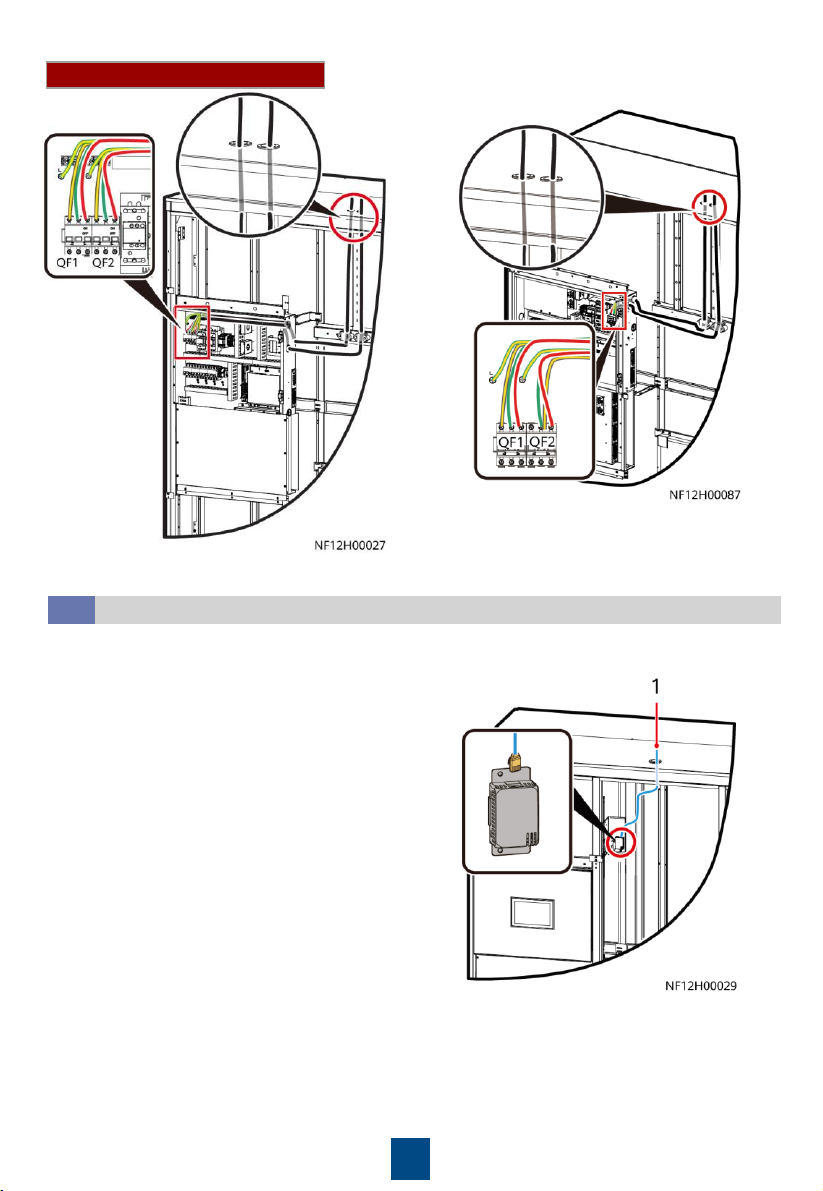

Cables Active power cable (4 x 10 mm2), standby power

cable (4 x 10 mm2), teamwork networking and

monitoring cables, and equipotential cable (6 mm2

outdoor copper cable)

Others Hoop iron, pipe support, thermal insulation foam,

dedicated glue for thermal insulation foam, and

thread sealant

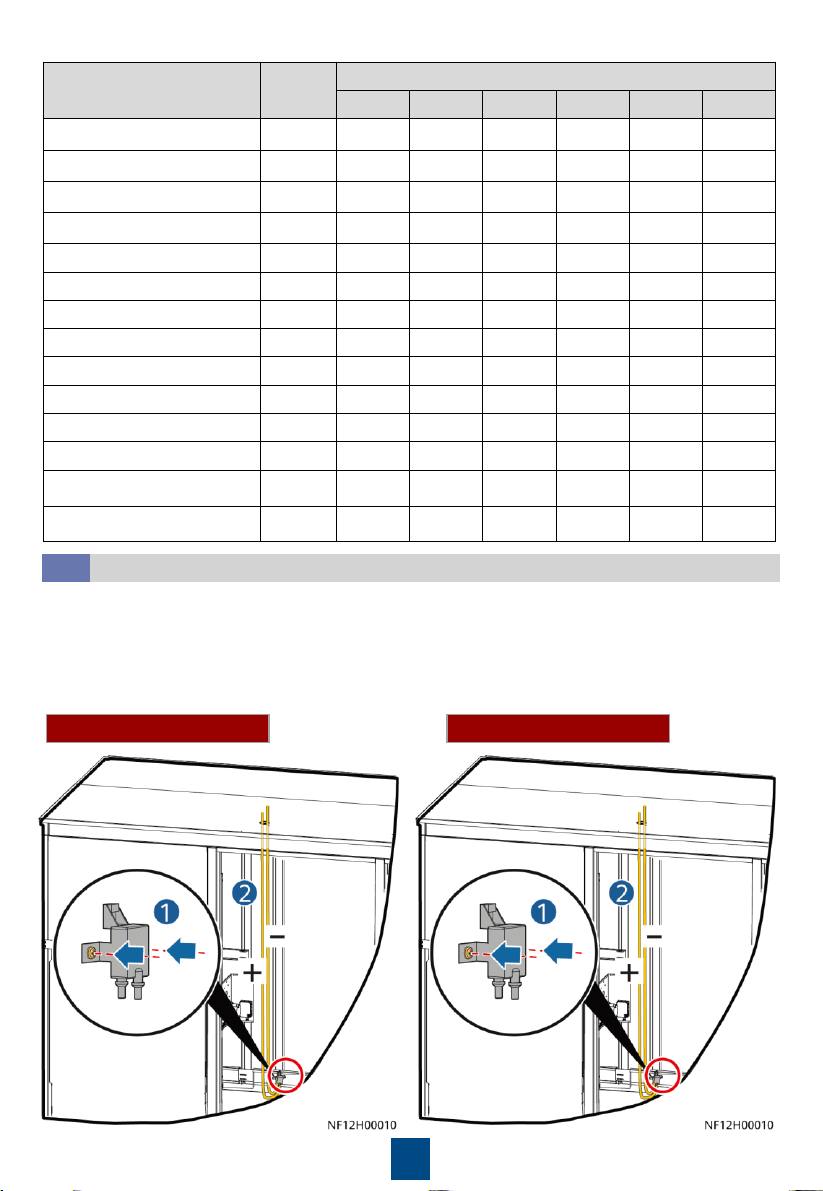

2Engineering Materials

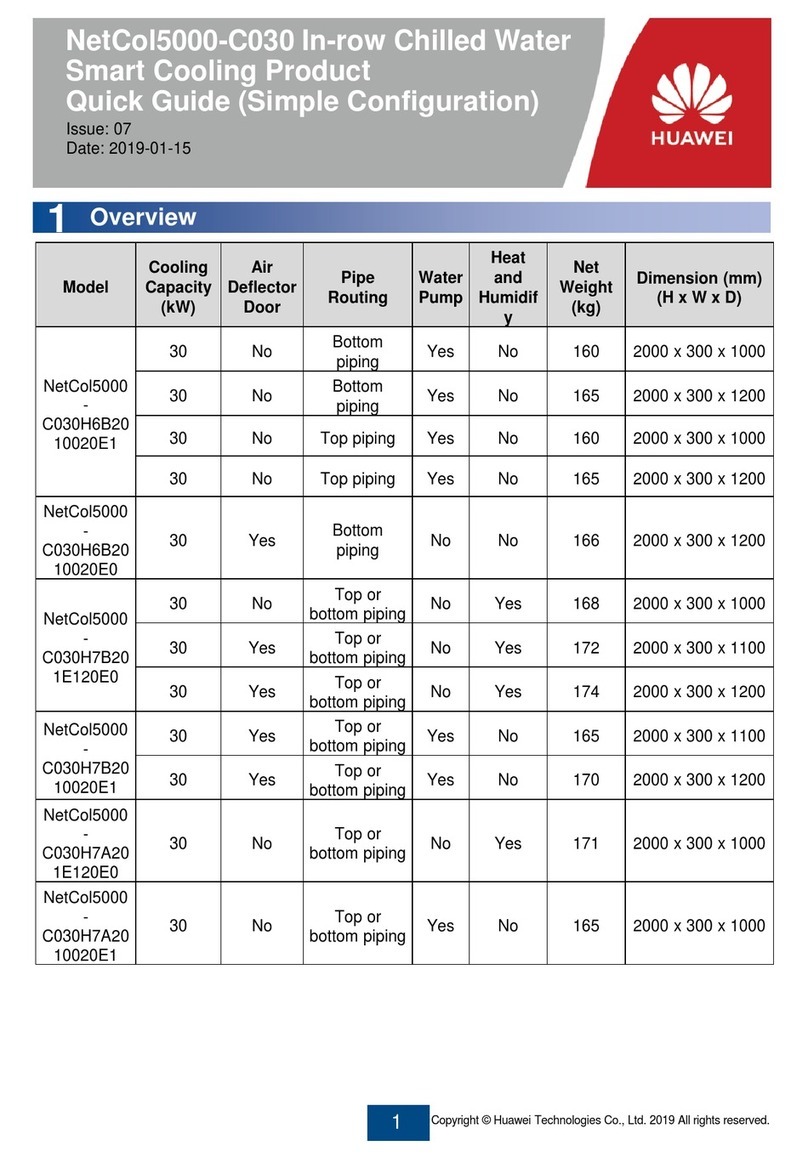

Product Model Pipe Routing Cable Routing Dimensions Without Packing (H

x W x D) (mm)

FusionCol8000-C210 Routed from top Routed from top 2450 x 2350 x 1100

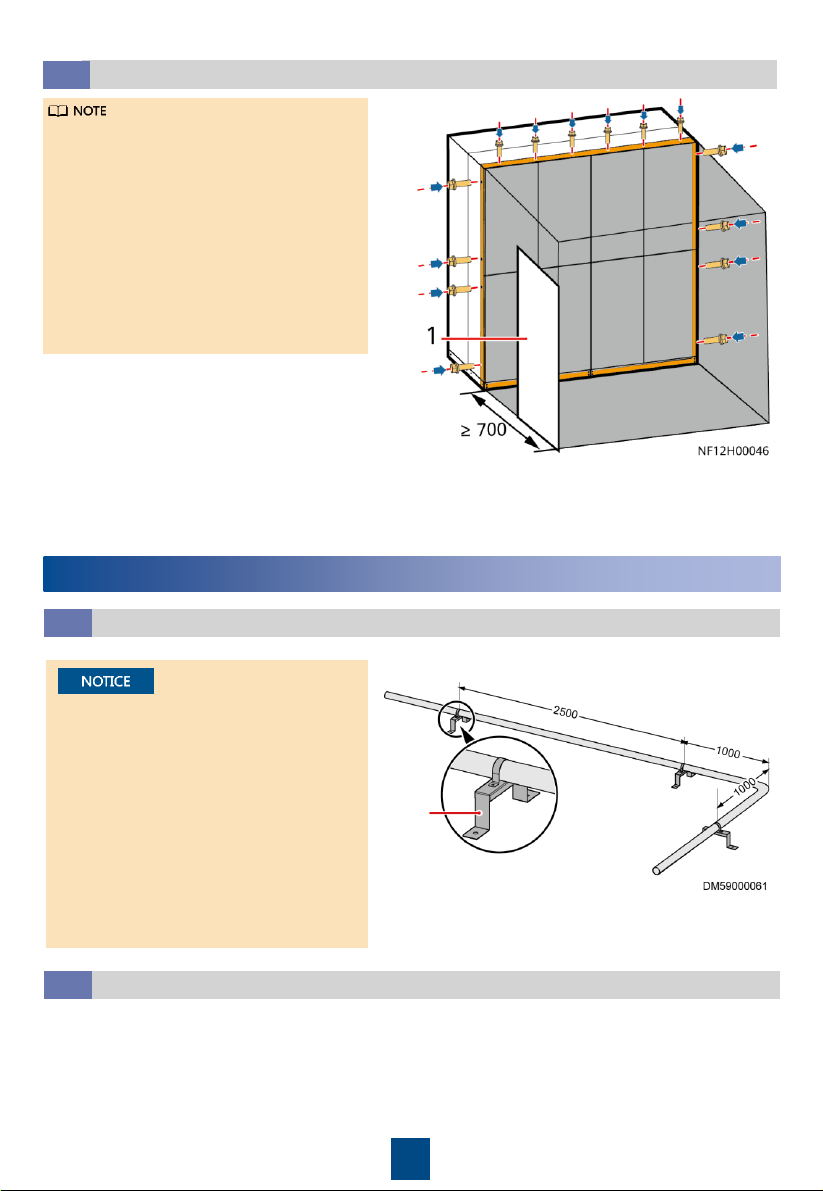

3Installing the Equipment

1. Read the related user manual or instructions before installing the FusionCol8000-C.

2. The unit in this document is a fully configured FusionCol8000-C. If some components are not

configured, skip the corresponding steps.

3. You are recommended to use tools that are fully insulated when installing devices.

4. Only engineers from the manufacturer or engineers certified by the agent are allowed to

install, commission, and maintain smart cooling products. Otherwise, personal injuries and

device damage may be caused, which is beyond the warranty range.

Copyright © Huawei Technologies Co., Ltd. 2022.

All rights reserved.