ii

Contents

1 Precautions …………….…………………………………………............................………….1

2 Tools for Installation ……………………………………….............................………………….2

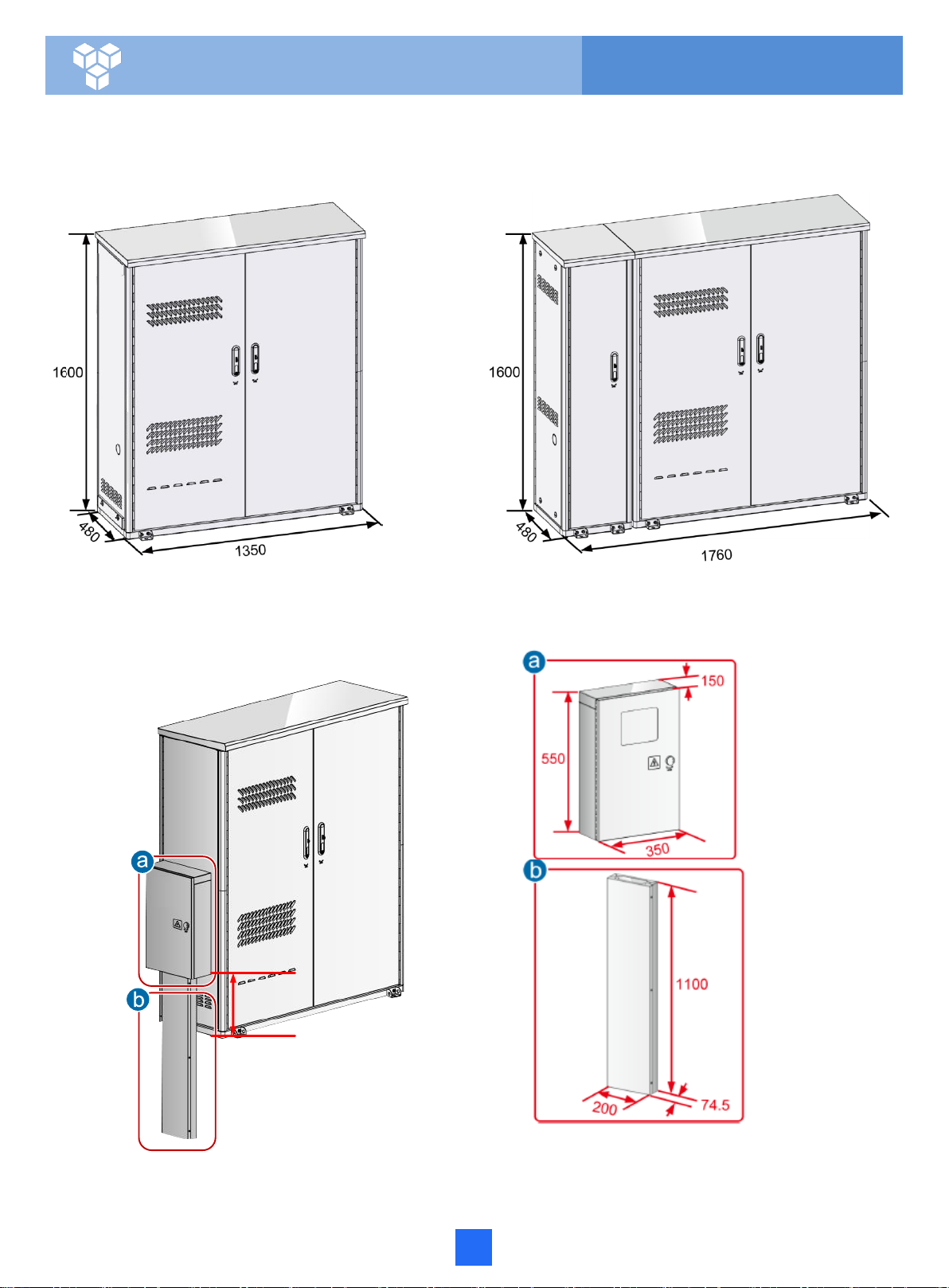

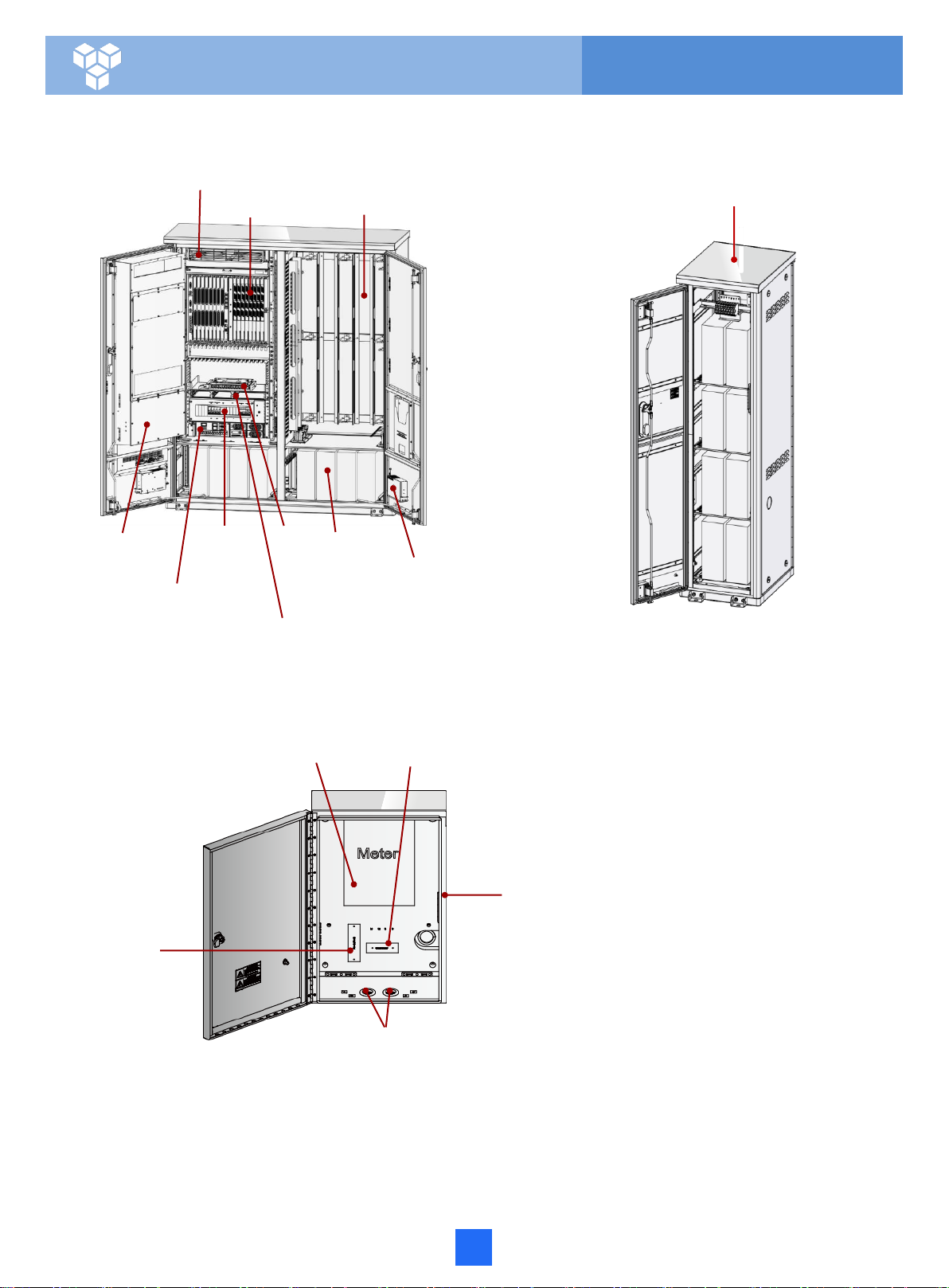

3 Appearance and Structure ……………………………………….............................…………….3

4 Installing the Cabinet on a Concrete Pedestal………….............................…………….8

4.1 Construct the Concrete Pedestal ………………………………………………………….8

4.2 Fastening the Cabinet ….………..................................................................12

5 Installing the Cabinet on an Underground Base……………...............................………..23

5.1 Appearance of the Underground Base............................ ...........................................23

5.2 Digging a Foundation Pit…... …... …... …... …... …...…...............................24

5.3 Laying the Underground Base.…..... .…......…........................................25

5.4 Filling Soil Back to the Foundation Pit………………………………………………26

5.5 Installing the Cabinet on the Underground Base..................................28

6 Routing Cables ………………………………………………...............................………..32

6.1 Routing the Cabinet PGND Cable.......................................................................32

6.2 Connecting Power Cables(AC Power Supply) ………………...............................34

6.3 Connecting Power Cables(RPS Power Supply). ………........................................36

6.4 Diagram of Cable Connections Between the RPS and MDF (RPS Power

Supply)………………………………………………………………………………….…….39

6.5 Installing the AC+RPRPower Module........................................................40

6.6 Connecting Power Cables(AC+RPRPower Supply).…........................................41

6.7 Diagram of Cable Connections Between the RPS and MDF (AC+RPRPower

Supply)…………………………………………………………………………….…….45

6.8 Connecting External Subscriber Cables(Copper Configuration or Optical/Copper Mixed

Configuration)………………………………………………………………………….…….48

6.9 Connecting Optical Cable and Optical Fibers (Upstream)..... .... ................................50

6.10 Connecting Optical Cable and Optical Fibers (Downstream, Optical

Configuration ) ………………………………….…………………...............51

6.11 Connecting Optical Cable and Optical Fibers (Downstream, Optical/Copper Mixed

Configuration) ……...................................................................53

6.12 Installing the Door Status Sensor Cable and Temperature Sensor (Scenario Where

the Battery Cabinet Is Deployed).... ............ ............ ......................56

7 Installing the Electronic Door Lock System………….………….………….…………..58

7.1 Appearance and Structure …….……….........................................................58

7.2 Installing the CCU …….………................................................................59

7.3 Installing the Door Lock(BOM: 02311EYT).………...................................60

7.4 Connecting the Power Cable of the CCU..…...................................63

7.5 Installing the Anti-Theft Screw ………..…........................................64

7.6 Post-Installation Check ……................................................................66