160K(i) 60 Hz Power Conditioner | Owners Manual 4

GENERAL DESCRIPTION

The Series 700AV/T-S Power Processor is designed to supply reliable, clean regulated power to critical

loads. An efcient design with state of the art micro-processor controlled solid state devices provide

immunity to all line disturbances.

The basic design consists of a three phase triple shielded isolation transformer with seven separate voltage

taps per phase. Output regulation is achieved by monitoring the input and automatically switching taps

anytime the input line sags or surges. The use of a triple shielded isolation transformer provides superior

common mode and transverse mode noise attenuation. Automatic switching occurs during current zero

allowing noise free switches for both leading and lagging power factor loads that are connected to the

Series 700AV/T-S.

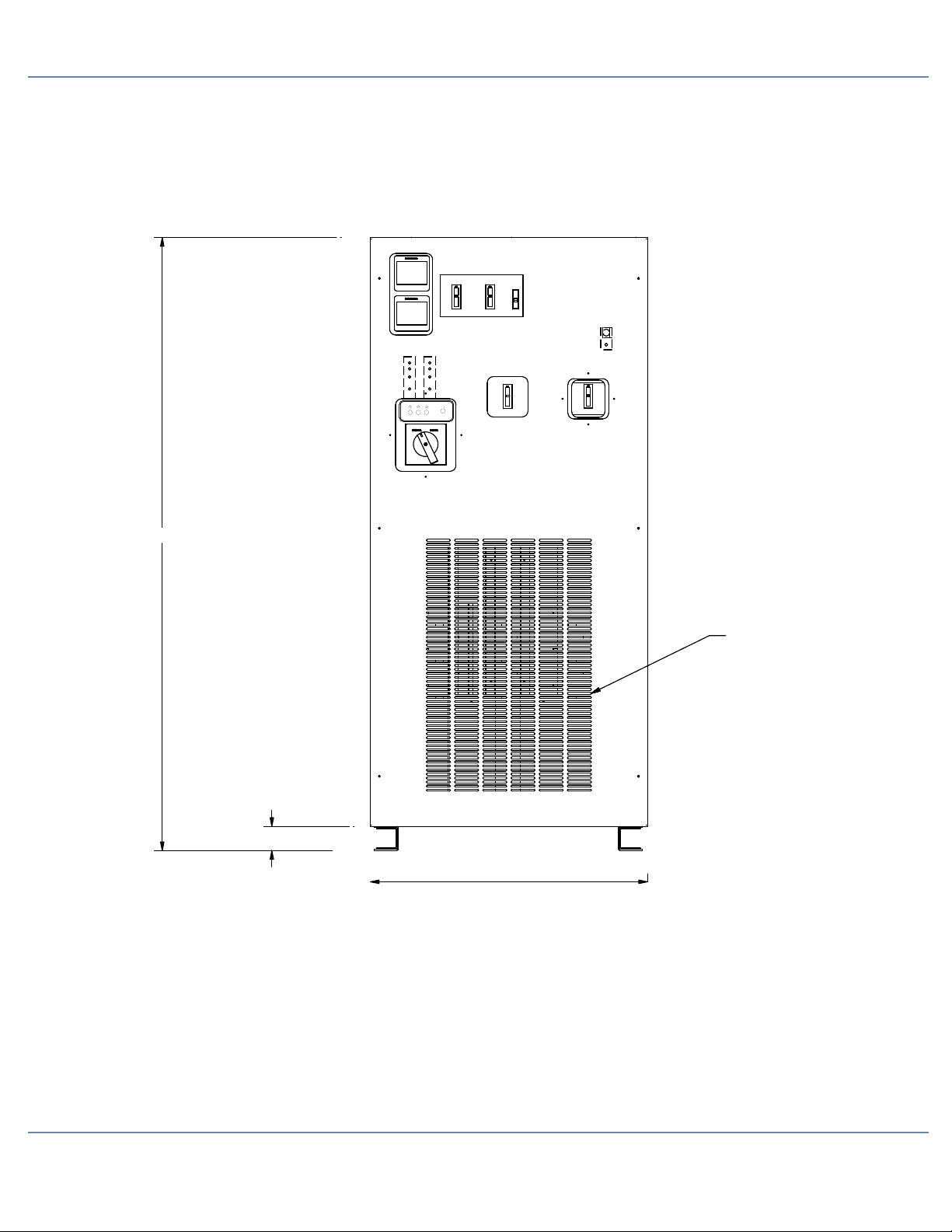

MONITOR

Monitoring of the Series 700AV/T-S is simple, clean and effective. Three green light indicators are utilized

to display “POWER ON”. These indicator lights are connected directly to the output (line to neutral for each

phase) and indicate that the Series 700AV/T-S is operating properly with just a quick glance.

The Series 700AV/T-S is also provided with “INPUT OUT OF RANGE” red indicating LEDs for each phase.

If any phase of the input voltage source exceeds the specied +10%, -15% from nominal, the appropriate

phase LED is illuminated.

In addition, a red “ALERT” light is provided as an over temperature indicator. If an over temperature

condition exists, the “ALERT” light will illuminate and shut down the output. Over temperature thermal

sensors are strategically located at critical points on the regulator assemblies and transformer. The main

AC input circuit breaker must be turned off in order to reset the “ALERT” light.

OUTPUT VOLTAGE METERS

Two (2) digital output meters are provided. One monitors the 208/120 VAC output and the other monitors

the 480/277 VAC output. Each meter monitors and displays Line-to-Line and Line-to-Neutral voltages.

Minimum and maximum voltage values are recorded in EPROM. High and low output voltage limit alarms

are programmable and a visual indication given if limits are exceeded.

PROTECTION

Protection is accomplished very effectively to minimize failures and the cost of repairs. A total of ve major

devices protect the Series 700AV/T-S.

1. The input is protected with an integrally mounted AC circuit breaker for abnormal current overloads

and provides a convenient means of disconnecting utility power.

2. The main transformer is protected by fuse links connecting the SCR regulators together, and are

designed to clear in the event that two or more SCR’s should fail. This will prevent a transformer tap

short and the possibility of transformer failure.

3. Overtemp sensing devices are mounted at critical points on the SCR regulating assembly and the

main transformer. When an overtemp condition exists the “ALERT” light will illuminate and hold until

the overtemp is corrected. There are no automatic shut-off circuits for the “ALERT” condition. The

main AC input breaker must be turned off in order to reset the “ALERT” light.

4. Each output of the Series 700AV/T-S is protected with an integrally mounted AC breaker for abnormal

current overloads and provides a convenient means of disconnecting power from the load.