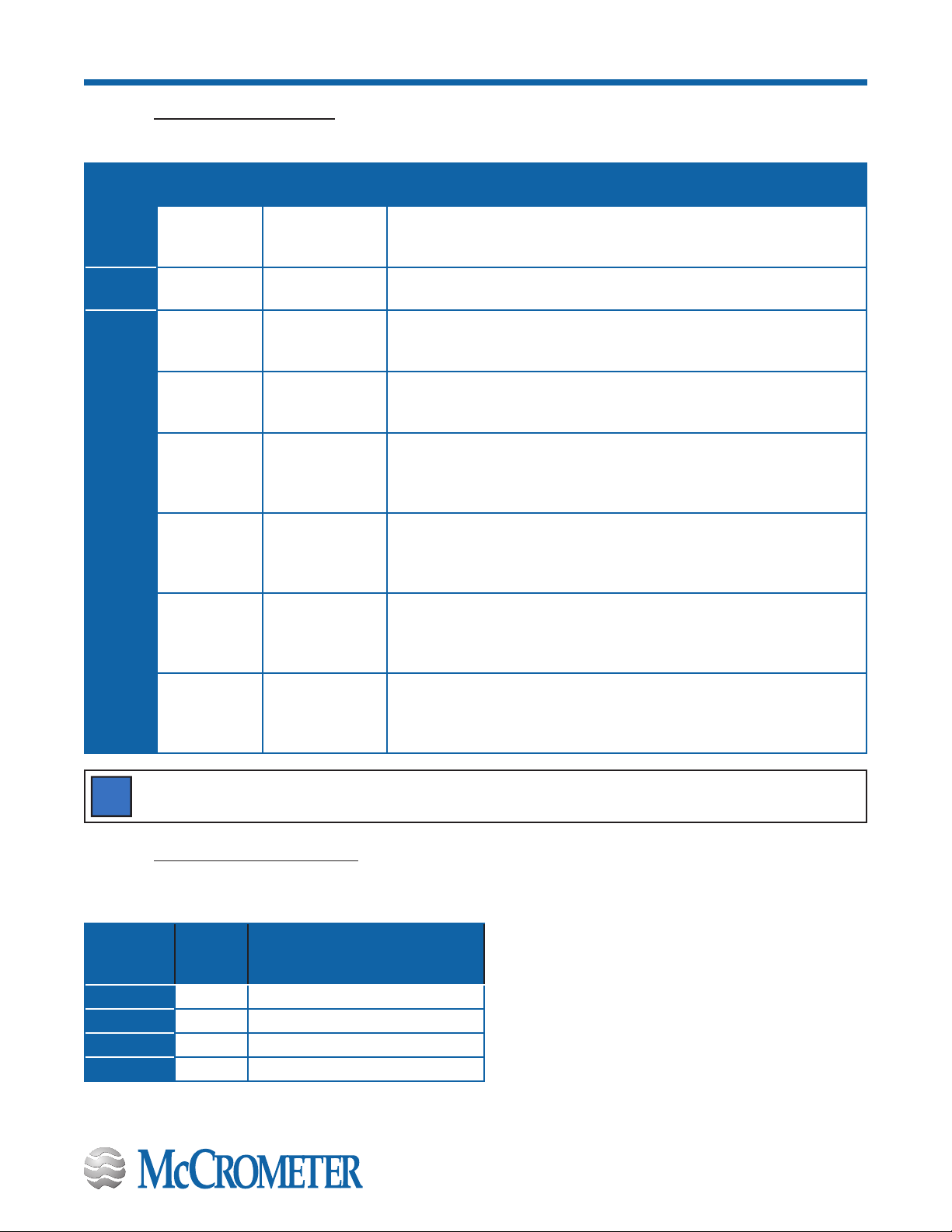

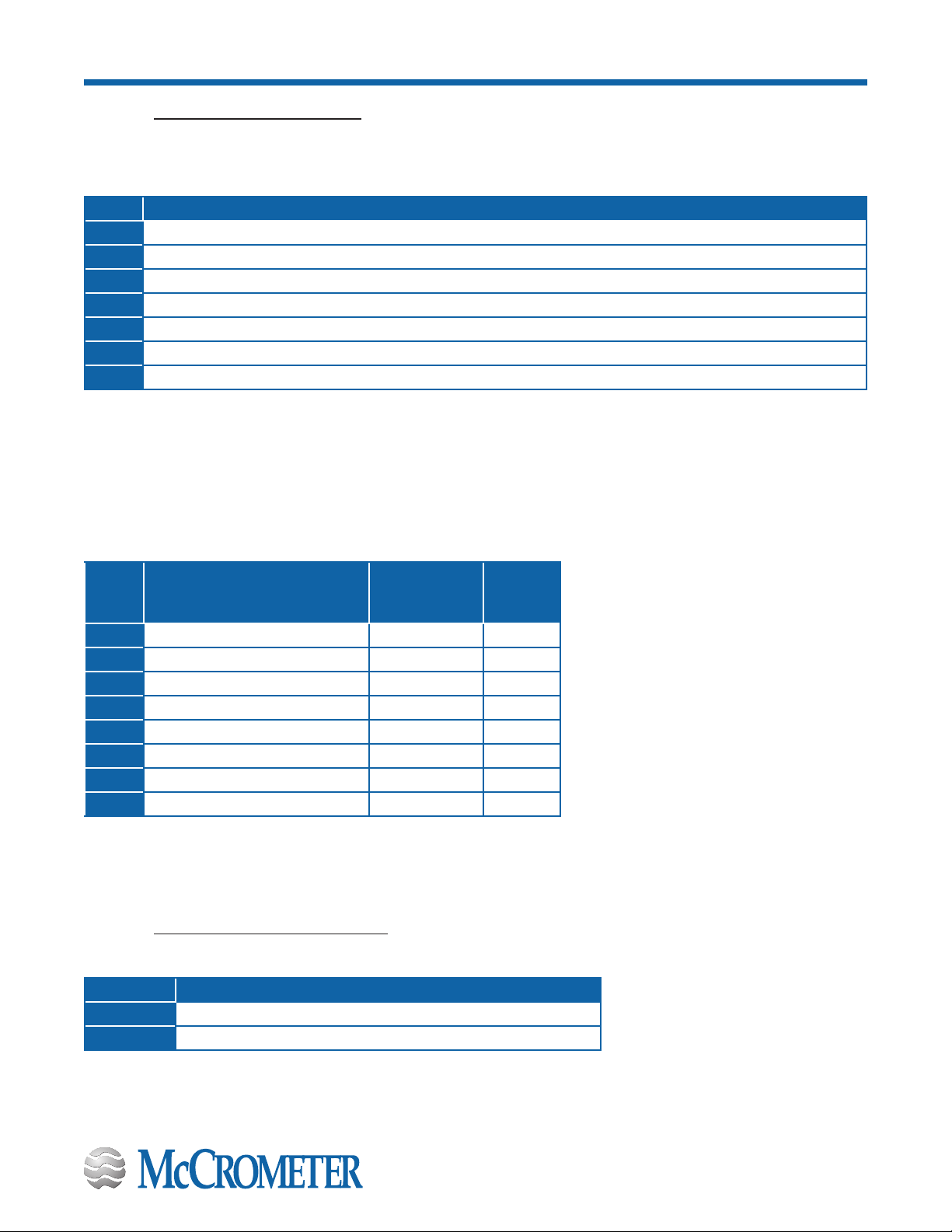

SAFETY............................................ 1

1.0 Introduction ................................. 2

1.1 Scope ......................................2

1.2 Purpose ....................................2

1.3 Who should use this document? .............2

1.4 Abbreviations and denitions ...............2

1.5 References ................................. 2

1.6 Device Identication........................ 2

2.0 Product Overview ............................ 2

3.0 Product Interfaces ........................... 3

3.1 Host interface ..............................3

3.2 Local Interfaces, Jumpers and Switches....... 3

4.0 Device Variables ............................. 4

5.0 Dynamic Variables ........................... 4

6.0 Status Information ........................... 5

6.1 Device Status ...............................5

6.2 Extended Device Status .....................5

6.3 Additional Device Status (Command #48).....5

7.0 Universal Commands......................... 5

8.0 Common-Practice Commands................. 6

8.1 Supported Commands ...................... 6

8.2 Burst Mode .................................6

8.3 Catch Device Variable .......................6

9.0 Device-Specic Commands ................... 7

10.0 Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10.1 Write Protect ............................... 9

10.2 Totalizers...................................9

10.3 Flow Direction .............................10

11.0 Performance................................10

11.1 Sampling Rates ............................10

11.2 Power-Up .................................10

11.3 Reset......................................10

11.4 Self-Test ...................................10

11.5 Command Response Times .................11

11.6 Busy and Delayed-Response ................11

11.7 Long Messages ............................11

11.8 Non-Volatile Memory ......................11

11.9 Modes.....................................11

11.10 Write Protection ...........................11

11.11 Damping ..................................11

APPENDIX A - CAPABILITY CHECKLIST ..............12

APPENDIX B - DEFAULT CONFIGURATION ...........12

Table of Contents

30125-48 Rev. 1.0 | 05AUG2021

Page ii