1

Precautions

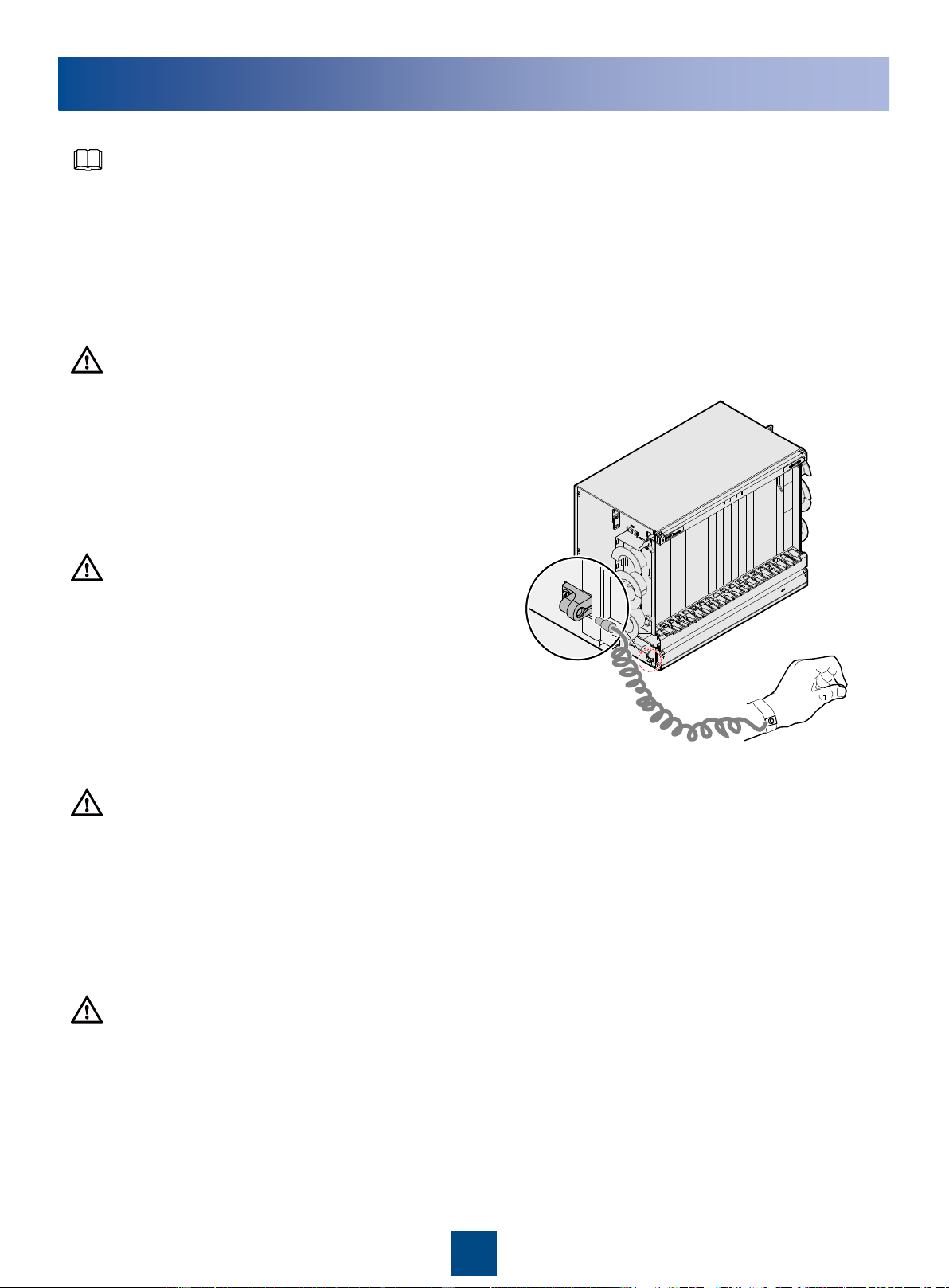

Electrostatic Discharge

Before touching the device, or holding the boards and IC

chips, wear the anti-static gloves or the anti-static wrist

strap to prevent the electrostatic discharge of the human

body from damaging the sensitive components. Ensure

that the other end of the anti-static wrist strap is well

grounded.

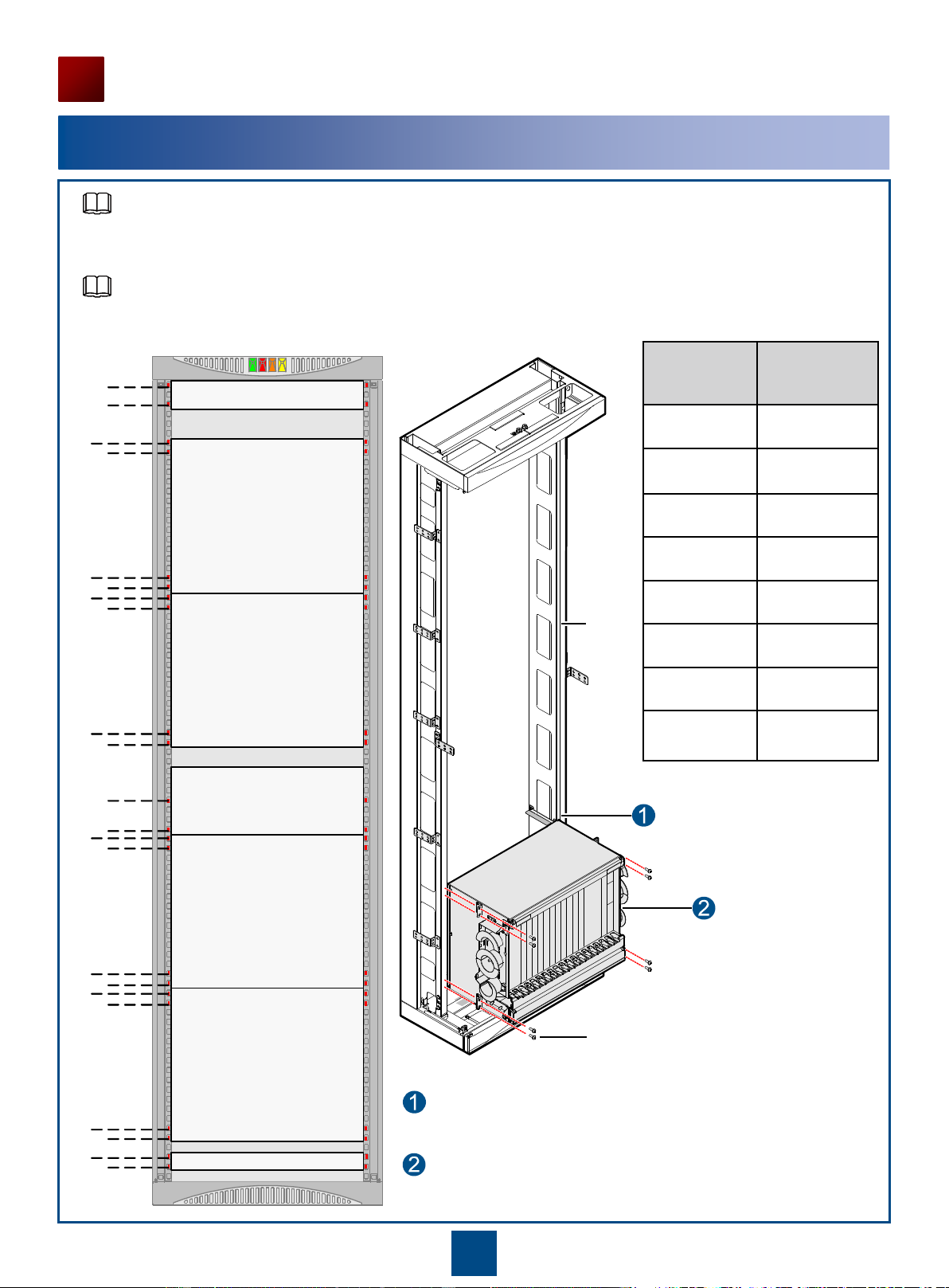

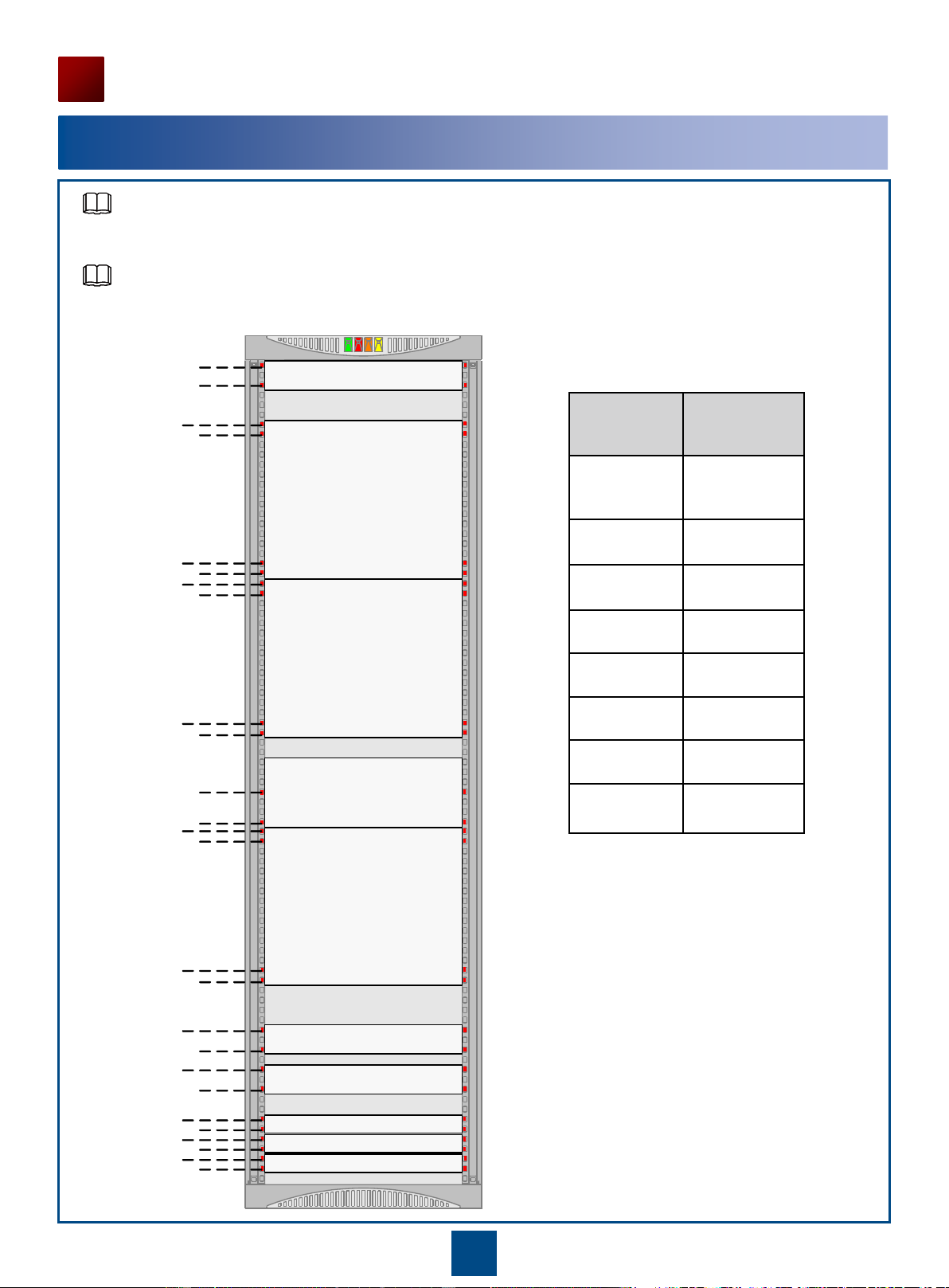

Checking Before Installation

Before starting installation, you should make the equipment room, power supply, ground cable, optical cables, and

other facilities in the equipment ready. When these installation conditions are confirmed, the installation may begin

according to the pre-designed layouts. For detailed requirements and related index, refer to Installation Reference.

Safety Information

When moving the cabinet, wear protective gloves to protect your

hands.

When moving the cabinet, take self-protection measures if the cabinet

inclines.

This document aims to provide simple and distinctive guidelines for hardware installation.

This document does not describe operations for the pre-delivery installation. Instead, this document describers only the

operations for on-site installation.

Bundling cables

The distance between cable ties or fiber holders inside the cabinet should be within 250 mm. (For subscriber cable, the

distance is 200 mm.)

The distance between cable ties for all cables and corrugated pipes outside the cabinet is determined according to the

distance between two horizontal beams. For the cable trough without beams, bundle the cables with the distance not

exceeding 250 mm between cable ties.

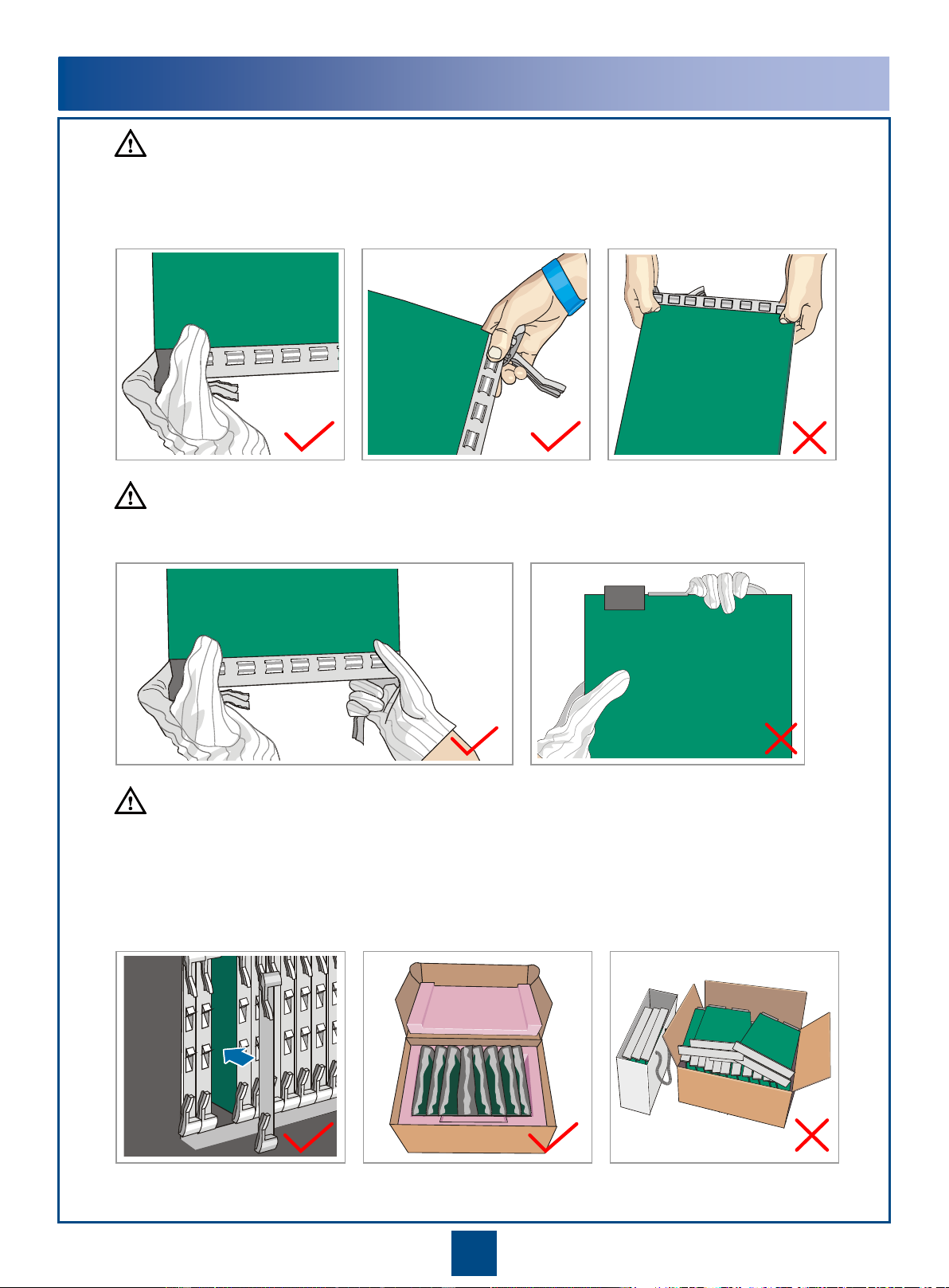

CAUTION

CAUTION

CAUTION

CAUTION

NOTE