I. Overview

The high-voltage withstand test of electrical equipment is one of the most important items

specified in the Preventive Test of Insulation. The withstand voltage test can be classified

into the AC withstand voltage test and the DC withstand voltage test. The AC withstand

voltage test can also be divided into power frequency, frequency conversion and 0.1Hz

ultra-low frequency test technologies. The 0.1Hz ultra-low frequency technology is the

latest technology and is the technology recommended by IEC (International

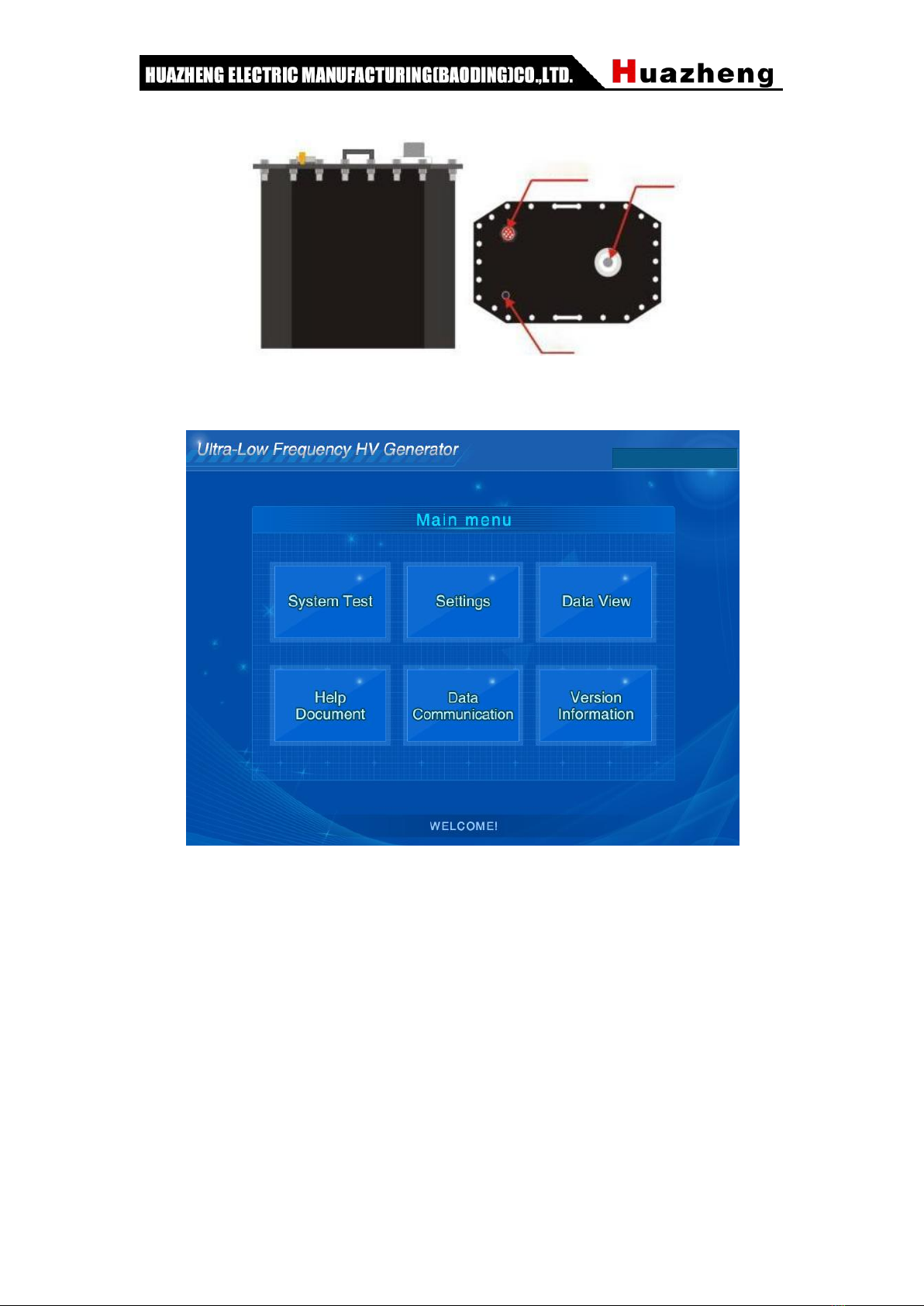

Electrotechnical Commission) at present. The new generation of VLFS series

microcomputer type 0.1 Hz ultra-low frequency high-voltage generators are core products

independently developed by FARSEE,they overcome many shortcomings of mechanical

domestic products, and its cost performance is much higher than the similar imported

products. It is particularly suitable for the withstand voltage test of electrical equipment

(e.g.: power cables, power capacitors, large- and medium-sized generators and motors,

etc.) with large insulation equivalent capacitance, and it meets the requirements of the

electric power industry standard General Technical Specification of Ultra-low Frequency

High-voltage Generator DL/T849.4-2004 newly issued by the country in 2004.

II. Advantages Of 0.1 Hz Ultra-low Frequency

Withstand Voltage Technology

The ultra-low frequency insulation withstand voltage test is actually an alternative method

of the power frequency withstand voltage test. When conducting power frequency

withstand voltage tests on test products such as large- and medium-sized generators,

motors, power cables, etc., as their insulating layers exhibit relatively large capacitance,

test transformers or resonance transformers with very large capacity are required. Such

huge equipment is not only cumbersome and expensive, but also very inconvenient to use.

In order to solve this conflict, the method of reducing the test frequency thereby reducing

the test power capacity is generally adopted in the world. Many years of theory and

practice at home and abroad have proved that replacing the power frequency withstand

voltage test with a 0.1 Hz ultra-low frequency withstand voltage test can not only have the

same equivalence, but also the size of equipment is greatly reduced, the weight is greatly

reduced, the capacity is about 1/500 of the power frequency theoretically, and it is simple

to operate. This is the main reason why developed countries generally adopt this method.

According to the actual situation of the power system in our country, the National

Development and Reform Commission has formulated the industry standard Ultra-low

Frequency (0.1 Hz) Withstand Voltage Test Method for XLPE Insulated Power Cable of