4

©Hubbell Incorporated | hubbellpowersystems.com

TD10321E Rev. B - 07/2021

©Hubbell Incorporated | hubbellpowersystems.com

TD10321E Rev. B - 07/2021

Overview

QUALIFIED PERSON

Only qualified trained and

competent personnel that

understand proper safety

procedures must select, install

and service this equipment.

Read and understand these

instructions before installing,

operating or maintaining this

equipment.

This guide is not a substitute for

adequate training and experience

in safety procedures for this type

of equipment.

SIGNAL WORDS

The signal words “DANGER”,

“WARNING” and “CAUTION”

(along with their assigned symbol)

throughout this manual indicate

the degree of hazard the user may

encounter. These symbols and

words are defined as:

DANGER

!

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

WARNING

!

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION

!

CAUTION indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

CAUTION

CAUTION used without the safety

alert symbol indicates a potentially

hazardous situation which, if not

avoided, may result in property

damage.

PRODUCT

The products covered by this

manual are the BP3 3-Pull

overhead by-pass switches

for medium voltage electrical

distribution switching.

These products are designed for

distribution switching only at

their rated capacities. They

cannot be field modified for

capacities other than what was

shipped with the units. If a

dierent capacity is desired,

contact your supervisor or factory

representative

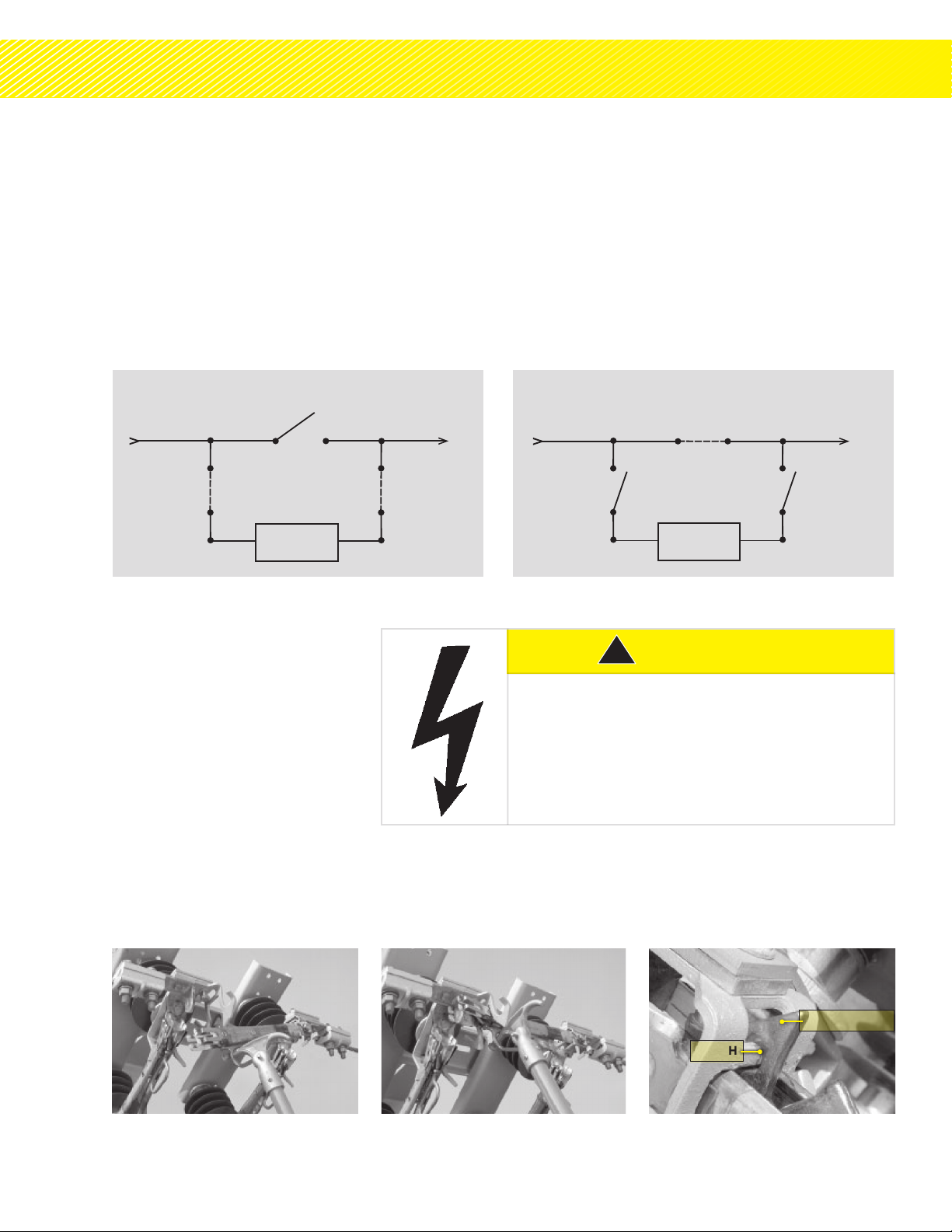

FUNCTION

These products are non-loadbreak

disconnect switches designed to

provide a means for by-passing,

disconnecting and isolating

reclosers or similar devices on

the electrical distribution system.

GENERAL

The BP3 By-Pass Switch is a

single-phase 3-blade, 3-pull,

hookstick operated switch. It is

used for manually disconnecting

a recloser without interrupting

normal electricalservice. Standard

variations are:

1. Right or left opening by-pass

blade operation

2. Switch mounting

3. Terminal connections

4. Loadbreak hooks on

disconnect blades.

The BP3 switch has no inherent

current making or breaking capacity.

The by-pass blade includes a hook

for use with a loadbreak tool. The

BP3 has no deadending provisions.

SPECIFICATIONS

Select the proper BP3 switch for

each installation with consideration

to voltage, continuous current,

short time current withstand,

lightning impulse withstand and

variations. If there is concern about

the use of this switch as rated,

consult your supervisor before

installation.

• Nominal voltage ratings of

15.0 kV, 27 kV or 38 kV

• Lightning Impulse peak

withstand ratings of 110 kV,

125 kV, 150 kV and 200 kV

• Continuous current rating of

600 or 900A (900A only for

units with 200 kV BIL rating)

• Short time current withstand

rating: 25 kA Symmetrical,

1 second 65 kA peak

Hazardous Voltage

Will cause severe personal injury, death, or property

damage.

Only qualified personnel should work on or around

this equipment after becoming thoroughly familiar

with this document and other publications regarding

this equipment.

DANGER

!