Page | v

CONTENTS

Safety Warnings.........................................................................................................................iii

1 Layout..................................................................................................................................... 1

1.1 Introduction...................................................................................................................... 1

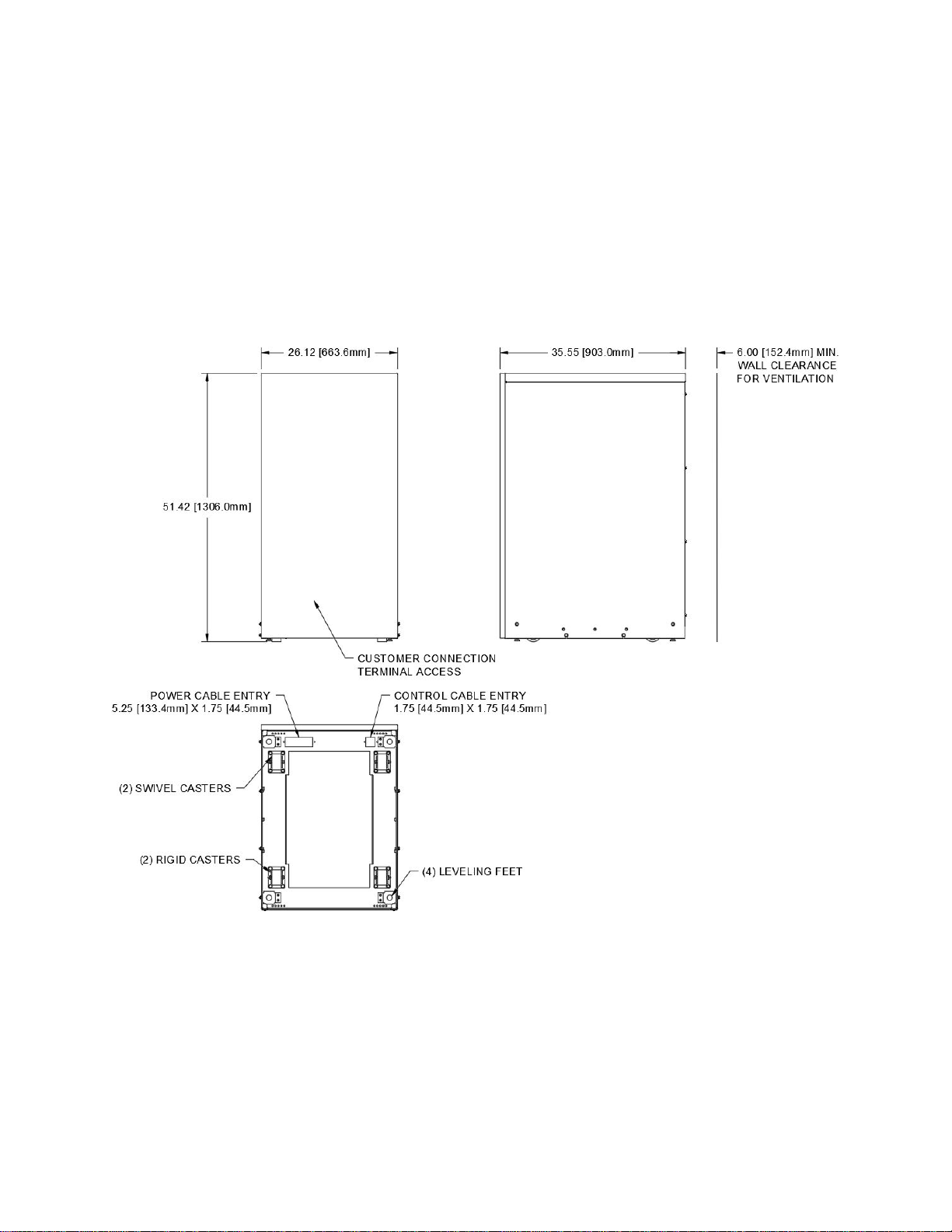

1.2 Layout.............................................................................................................................. 1

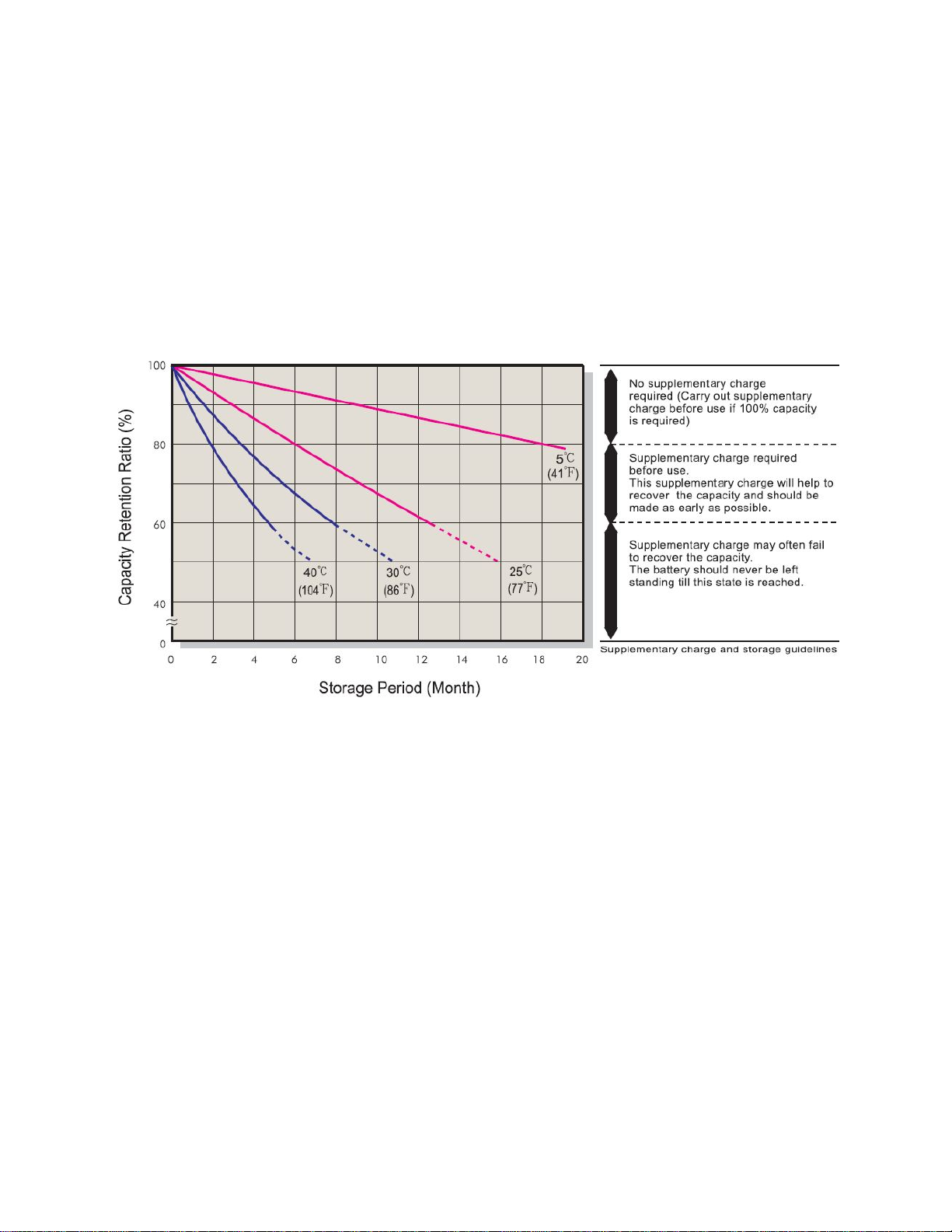

1.3 Battery Life....................................................................................................................... 2

2. Battery Cabinet Setup........................................................................................................... 3

2.1 Inspecting the Equipment................................................................................................. 3

2.2 Floor Loading................................................................................................................... 3

2.3 Clearances....................................................................................................................... 3

2.4 Unloading the Cabinet(s).................................................................................................. 4

2.5 Placing the Cabinet.......................................................................................................... 6

3. Electrical Installation .............................................................................................................. 7

3.1 Wiring Preparation............................................................................................................ 7

3.2 Connecting to the Extended Battery Cabinet...................................................................10

4. Circuit Breaker Interface .......................................................................................................12

5. Battery Removal, Installation, and Service............................................................................13

6. Maintenance .........................................................................................................................15

Table 1 - Symbols......................................................................................................................iii

Table 2 - Model Floor Loadings.................................................................................................. 3

Table 3 – Terminal Tightening Torques and Wires Sizes..........................................................11

Table 4 – Replacement Batteries and Operating Temperatures................................................15

Figure 1 - The Trident TRF Battery Cabinet............................................................................... 1

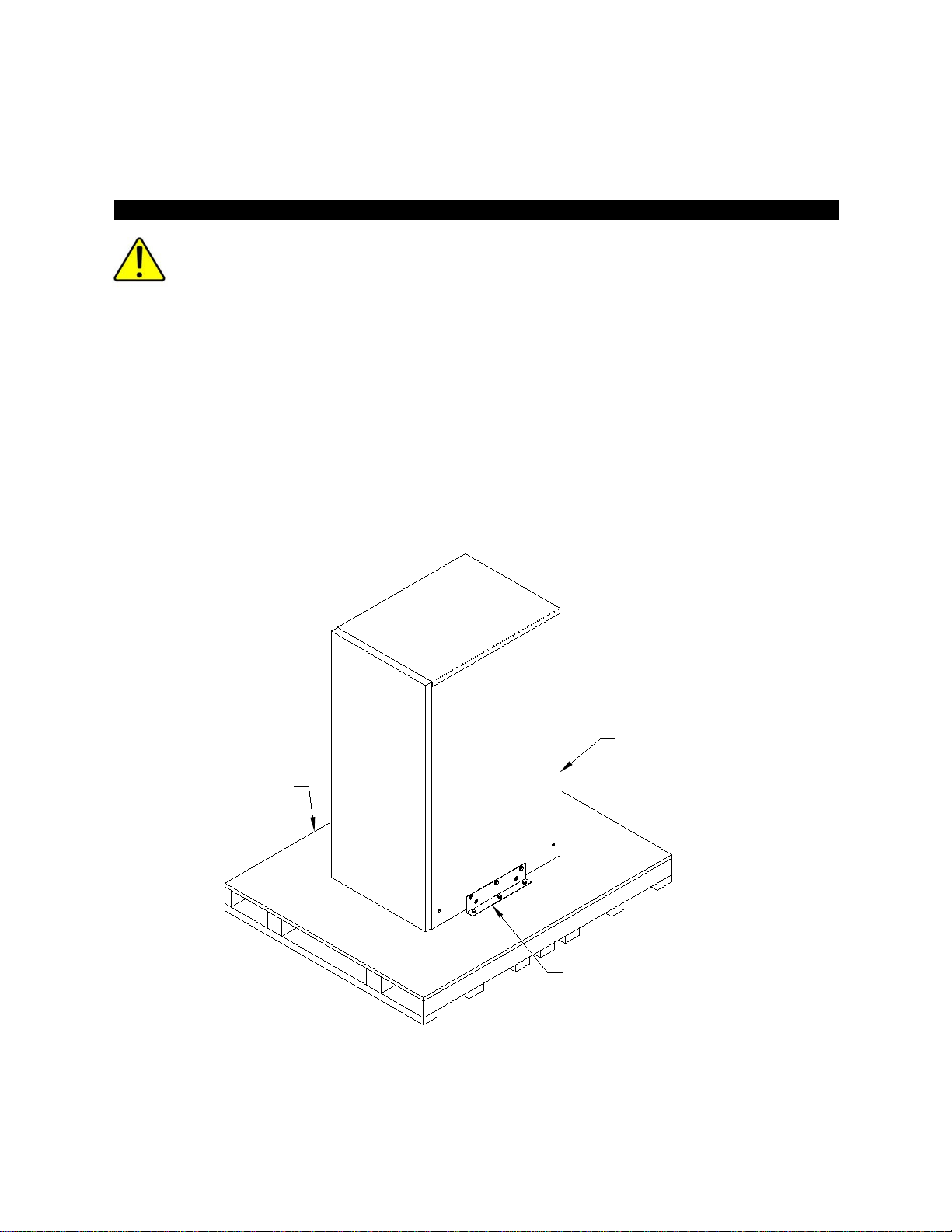

Figure 2 - Extended Run Time Battery Cabinet on Shipping Pallet............................................. 4

Figure 3 - Shipping Bracket........................................................................................................ 5

Figure 4 - Lifting Fork Area......................................................................................................... 6

Figure 5 – Leveling Foot Being Adjusted Down To Floor............................................................ 6

Figure 6 - Removing the UPS Front Panel................................................................................. 8

Figure 7 - Bottom View of Cabinet.............................................................................................. 9

Figure 8 – Circuit Breaker Panel................................................................................................ 9

Figure 9 - Connection Panel......................................................................................................10

Figure 10 – Communication Interface Board Connections ........................................................12

Figure 11 – Battery Bus Bar......................................................................................................13

Figure 12 – Battery Tray ...........................................................................................................14

Figure 13 – Cabinet Schematic.................................................................................................16