INSTALLATION

WARNING / CAUTION

DO NOT TURN ON THE ELECTRIC POWER SUPPLY to this equipment until heater is

completely filled with water and all air has been released. If the heater is NOT filled with water

when the power is turned on, the heating elements will burn out.

For protection against excessive pressures and temperatures, local codes require the

installation of a temperature-and-pressure (T&P) relief valve certified by a nationally

recognized laboratory that maintains periodic inspection of production of listed equipment of

materials, as meeting the requirements for Relief Valves and Automatic Gas Shutoff for Hot

Water Supply Systems, ANSI Z21.22. THE CUSTOMER IS RESPONSIBLE TO PROTECT

PROPERTY AND PERSONNEL FROM HARM WHEN THE VALVE FUNCTIONS.

All water heaters havea risk of leakage at some unpredictable time. ITIS THE CUSTOMER'S

RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER ADEQUATE MEANS, SO

THAT THE RESULTANT FLOW OF WATER WILL NOT DAMAGE FURNISHINGS OR

PROPERTY.

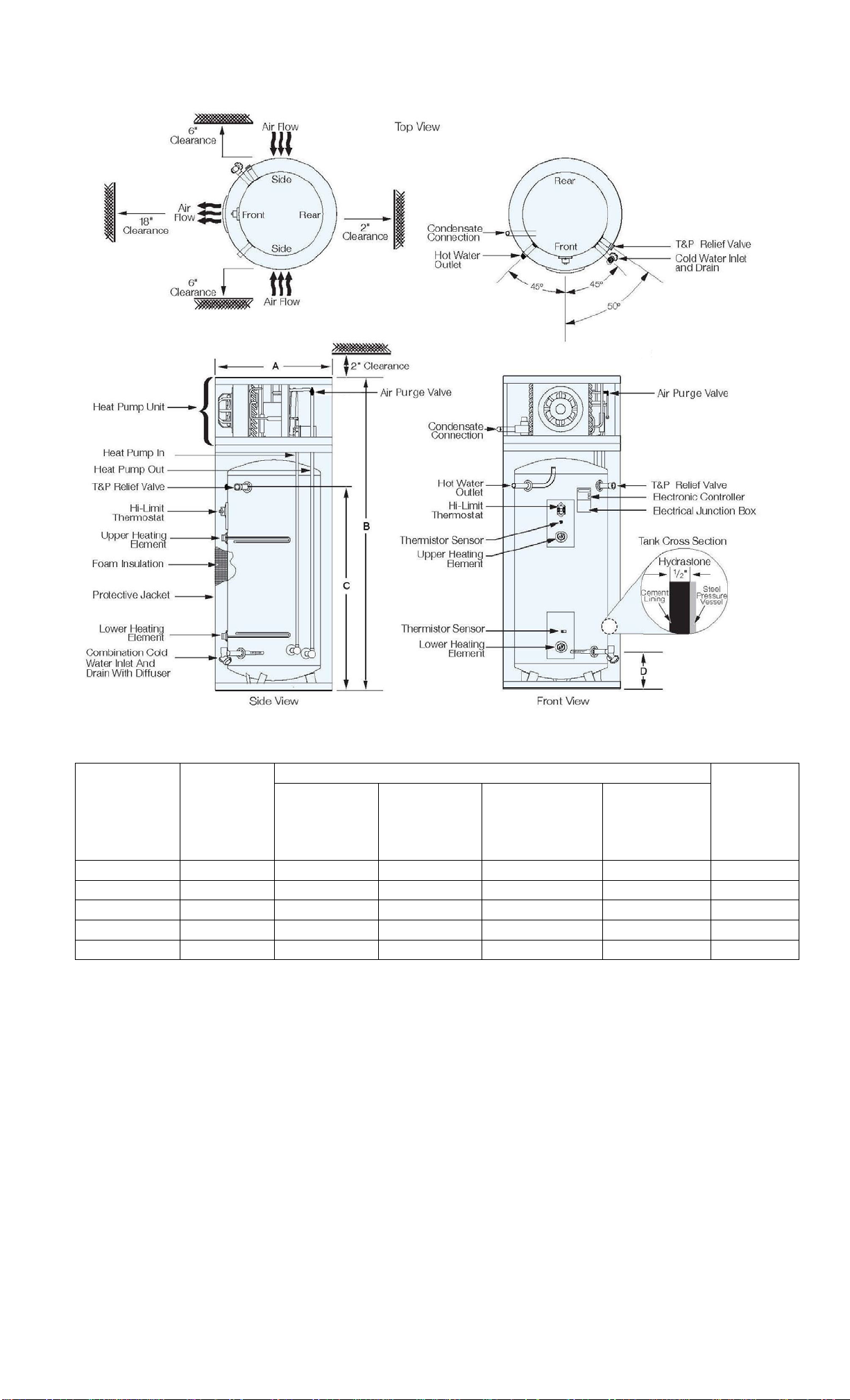

Water Heater Placement

1. Place the heater on a solid foundation in a clean, dry location nearest to the point of

most frequent hot water use. If the heater is to be raised off the floor, the entire bottom

of the heater should be supported by a solid surface.

2. The water heater must be installed with the minimum clearances as shown on page 5.

3. Do not install in an area where flammable liquids or combustible vapors are present.

4. The water heater should be protected from freezing and waterlines insulated to reduce

energy and water waste.

5. The space that the water heater is installed must be no less than 10’ x 10’ x 7’ high

(700 cubic feet). If a smaller space is used, there must be louvers installed in the space

that will allow for 450 CFM air flow.

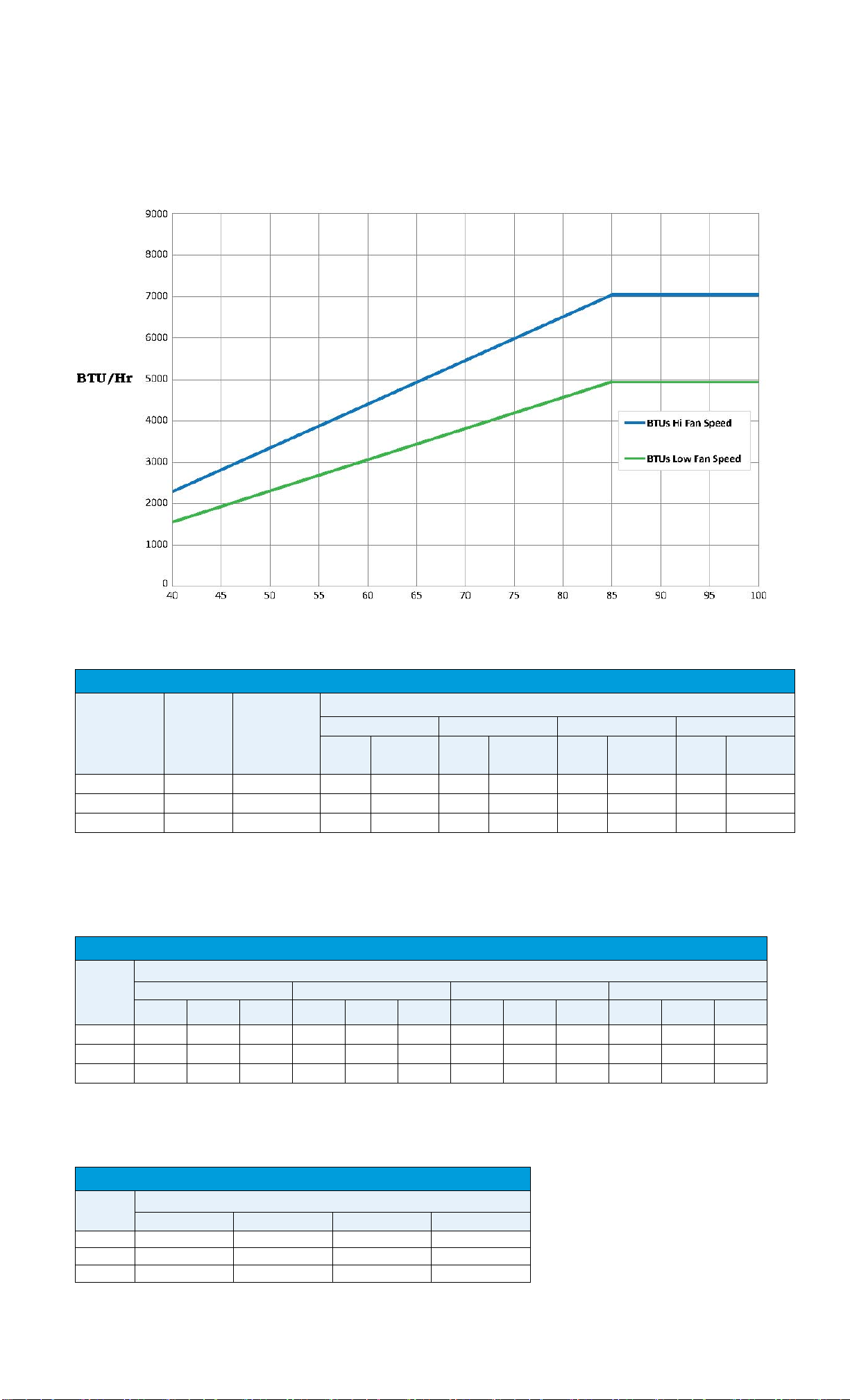

6. The installation location must not be cooler than 40°F. Locations with warmer

ambient air (ex. furnace rooms) are more advantageous as they provide abundant

“free” heat.

7. The heat pump dehumidifies the air and as a result produces condensate which must be

piped to a drain or outdoors.

Piping Installation

NOTE: The most effective means for preventing deterioration from accelerated corrosion

due to galvanic and stray current is the installation of dielectric fittings/unions. The installation

of these fittings is the responsibility of the installing contractor.

1. Connect the cold water inlet and hot water outlet to the appropriate connections as

shown; refer to the drawing for location and sizes.

NOTE: Certain models are supplied with a flow measuring device (flowmeter) and

temperature measuring device (thermistor) to be installed on the cold water supply

side. These items are shipped pre-wired into the unit and stored in the heat pump

compartment. The flowmeter should be installed in-line with the cold water supply

piping with the arrow pointing toward the water heater. The thermistor should be

secured to the outside of the cold water piping and covered with insulation.

2. Install the combination temperature and pressure safety relief valve in the tapping

provided. Note that this is required by law for safety considerations.

3. Install a relief valve overflow pipe to a nearby floor drain. CAUTION: No valve of

any type should be installed between the relief valve and tank or in the drain line.

8