02

DDB Lubrication Pump Series for multi-point lubrication frequency is

very low, lubrication points not more than 50 points, nominal pressure

of 100bar in multi-line centralized lubrication system.

Directly or through single-chip device to the oil-grease to the

lubrication points for the delivery of the device, particularly suitable

for crushing machine, forging machine, terminal line of cranes,

presses machines etc.

-Multi points from 10-36

- Tank volume of 7L and 23L

- Medium: NLGI 0# ~ 2# of American standard

grease classification

Lubrication Pump DDB Series Features:

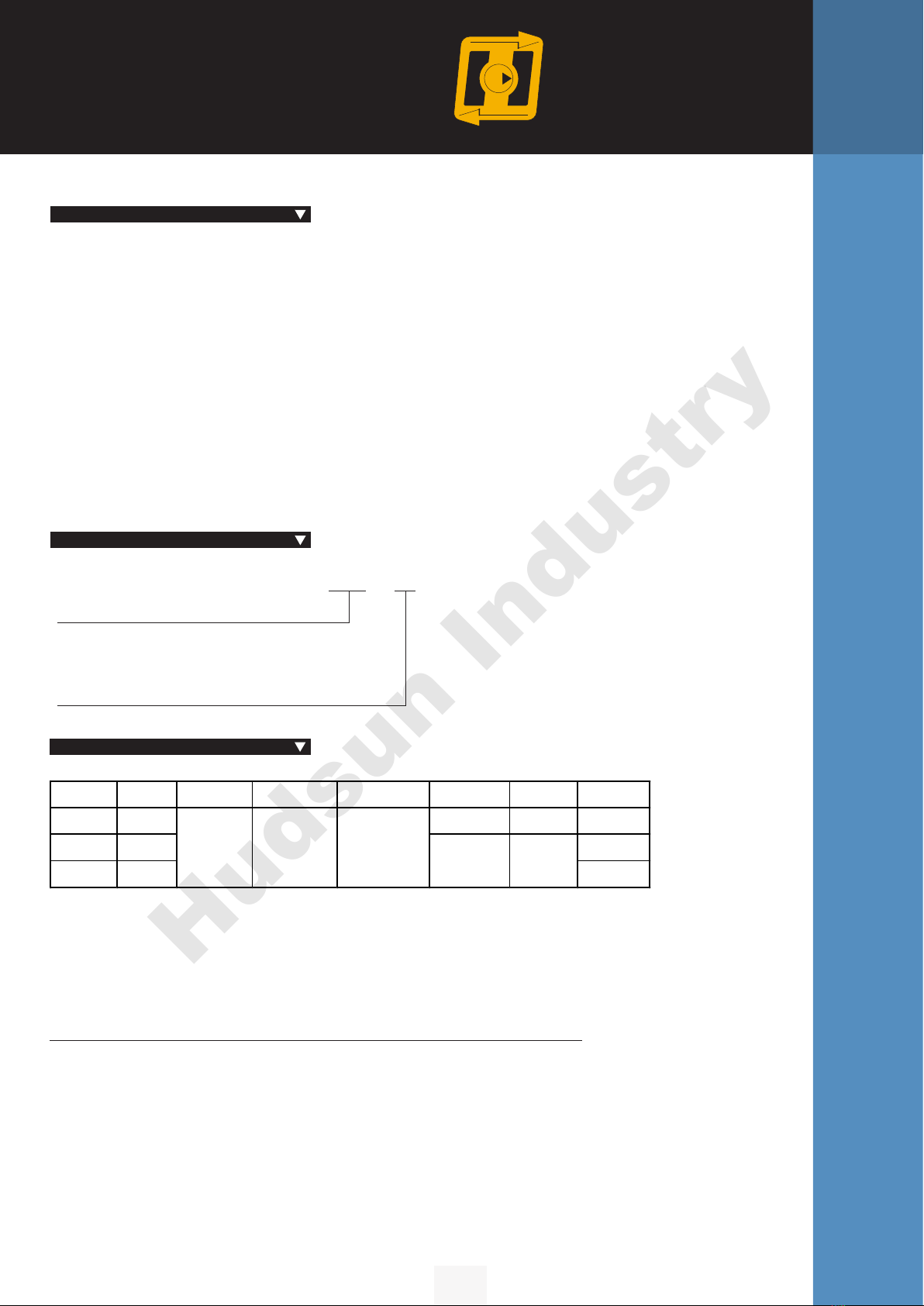

Model Port Nos. Pressure Oil feeding Feeding time Tank Volume Power Weight

DDB-10 10 7L 0.37KW 32KGS

DDB-18 18 56KGS

DDB-36 36 72KGS

100bar 0~0.2 mL/tim e 13/min

23L 0.55KW

DDB - 10

Multi-point lubrication pump

Service oil ports:

10= 10ports

18= 18ports

36= 36ports

Lubrication Pump DDB Order Code

Lubrication Pump DDB Technical Data

Note Before Operation:

1. The DDB pump should be installed in the more appropriate temperatures environment with less

dust, easy to fill grease, convenient adjustment, inspection and maintenance of the pump. The

filter screen for grease feeding is not less than 0.2mm accuracy, should be regularly cleaned.

2. To fill the grease, which must use the SJB-D60 series manual pump or DJB-F200 series electric

power pump to inject the grease through oil filling port of the reservoir.

please note: not to start the motor if no grease inside the reservoir.

3. The suitable medium for DDB pump : the grease penetration not lower than 265 ( 25 ℃, 150g)

1/10mm (American standard grease classification: NLGI 0# ~ 2# ) .

4. According to arrow rotation to connect the electrical wiring of motor, the direction shall not be

reversed.

5. Filling in reducer cavity with oil (Industrial gear oil HL-20) before operating the pump to the

required position, except no reducer cavity.

The oil in reducer cavity should be changed within 200 hours for the first time operation, then the

oil should be replaced in every 2000 working hours, except no reducer cavity.

6. The pump should be kept clean, forbidden to add the grease from the cover in order to avoid the

dirt into the pump.

HUDSUN INDUSTRY CO., LTD

www.hudsunindustry.com

sales@hudsunindustry.com

HUDSUN

INDUSTRY CO., LTD

DDB SERIES

LUBRICATION PUMP

02