PAGE 5

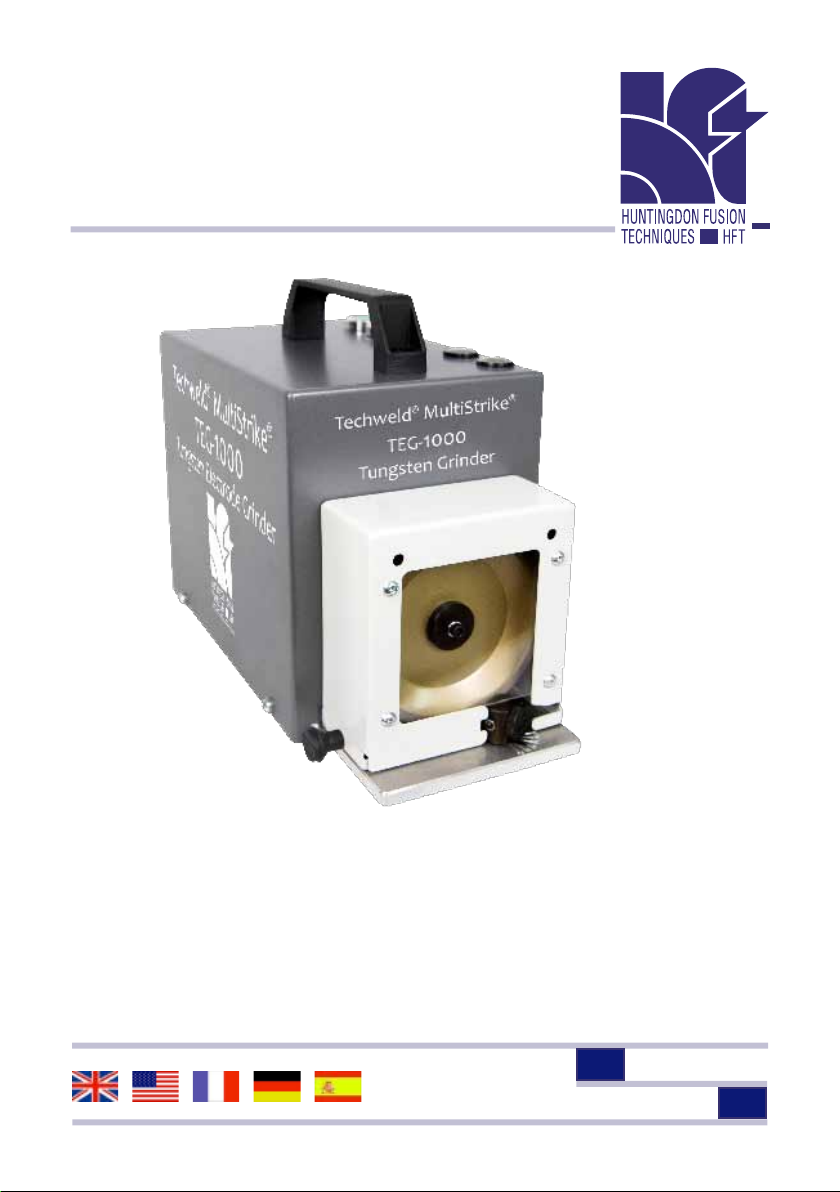

INSTRUCTIONS FOR USE

before they are allowed to use the TEG-1000 Tungsten Electrode

Grinder.

The parts are all named in the diagram on pages 10 and 11, so you

1. Set the grinder on a suitable bench and check that it is stable.

to obtain stability. Plug it in to your mains supply.

2. Loosen the angle guide key then set the arrow on the collet

block to the desired angle printed on the base of the unit. Once

the desired angle is selected, tighten the angle guide key.

3.

the tungsten to be ground. Then insert the tungsten into that

hole.

4. Please ensure the operator is wearing the correct safety items

before starting to operate this unit.

5. Rotate the multi hole tappet until the tungsten touches a suitable

place on the wheel. NOTEMUST set the tungsten against

the FACE of the wheel not the edge of the wheel.

6.

to start the motor.

7. Re-insert the tungsten carefully through the selected hole in the

multi hole tappet until it meets the wheel and starts to grind

and turn the tungsten with a light pressure, between the thumb

NOTE

for grinding are shown on table 1 on page 6.

8.

hole tappet and turn off the motor using the red push off switch.

9.