Table of Contents

General Information ........................................................................ 1

TOOLS........................................................................................ 1

MAXIMUM TORQUE VALUES ........................................................... 1

1. Operation of the Hurricane SCH25 ............................................... 3

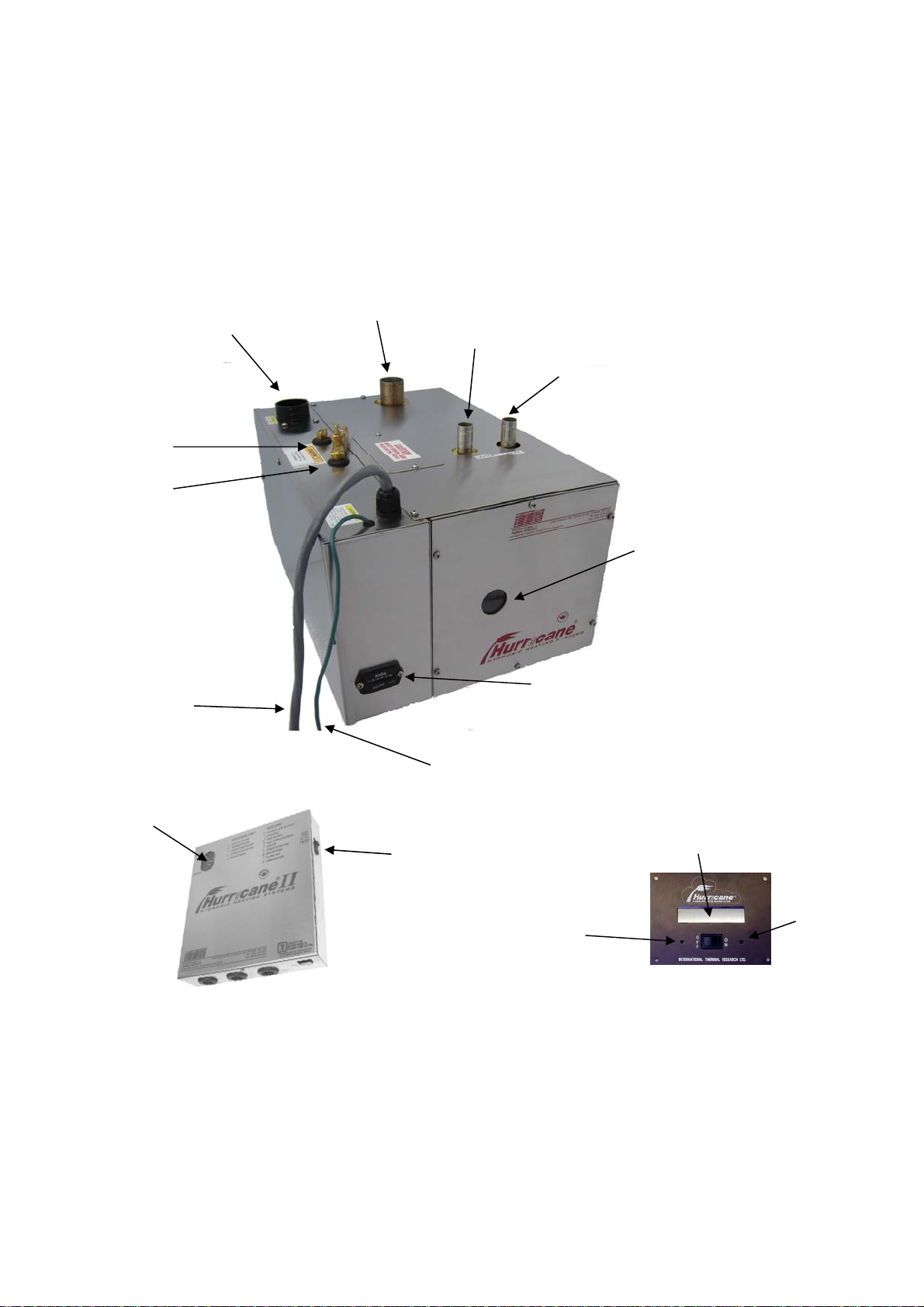

1.1. Component Views................................................................ 4

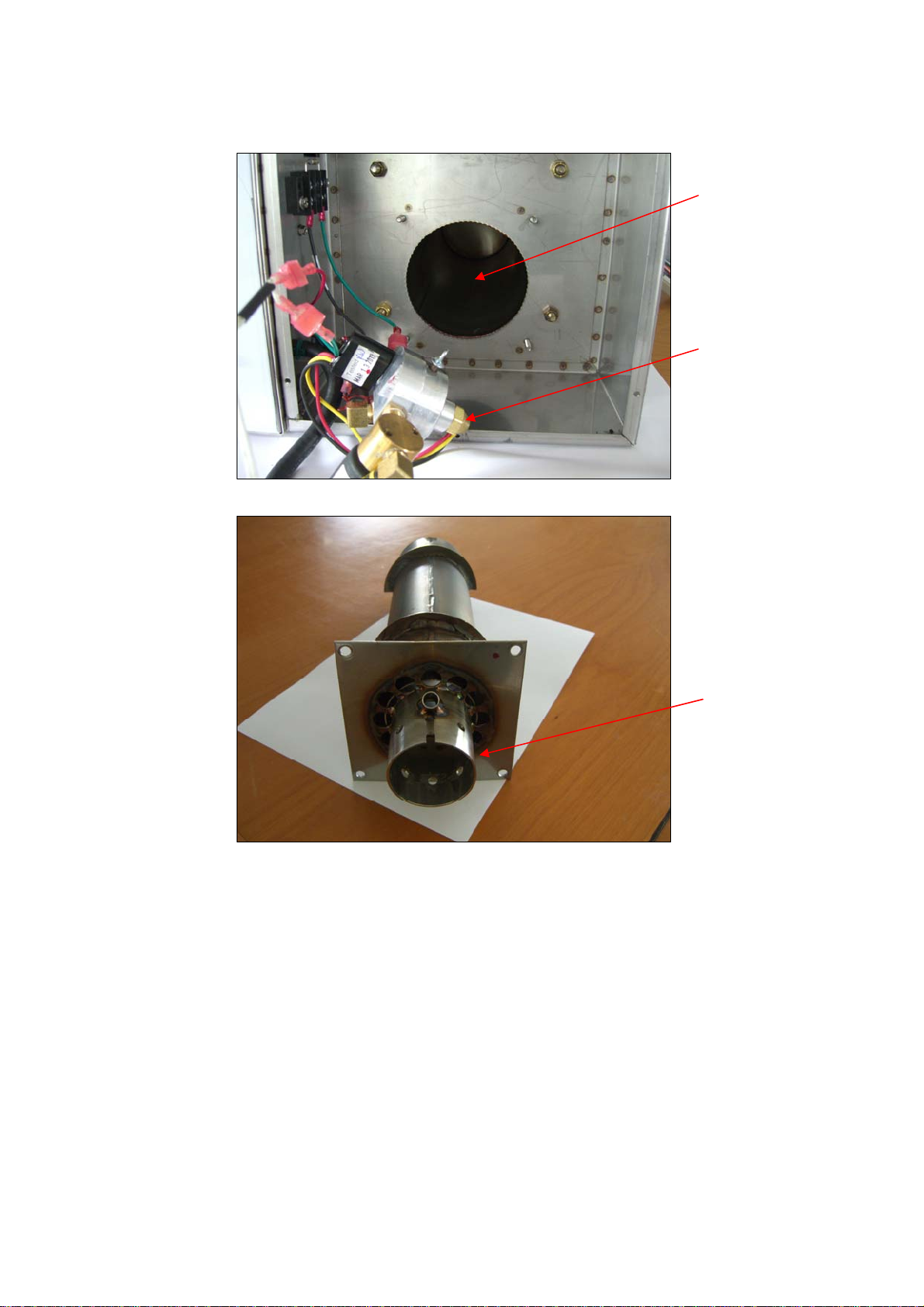

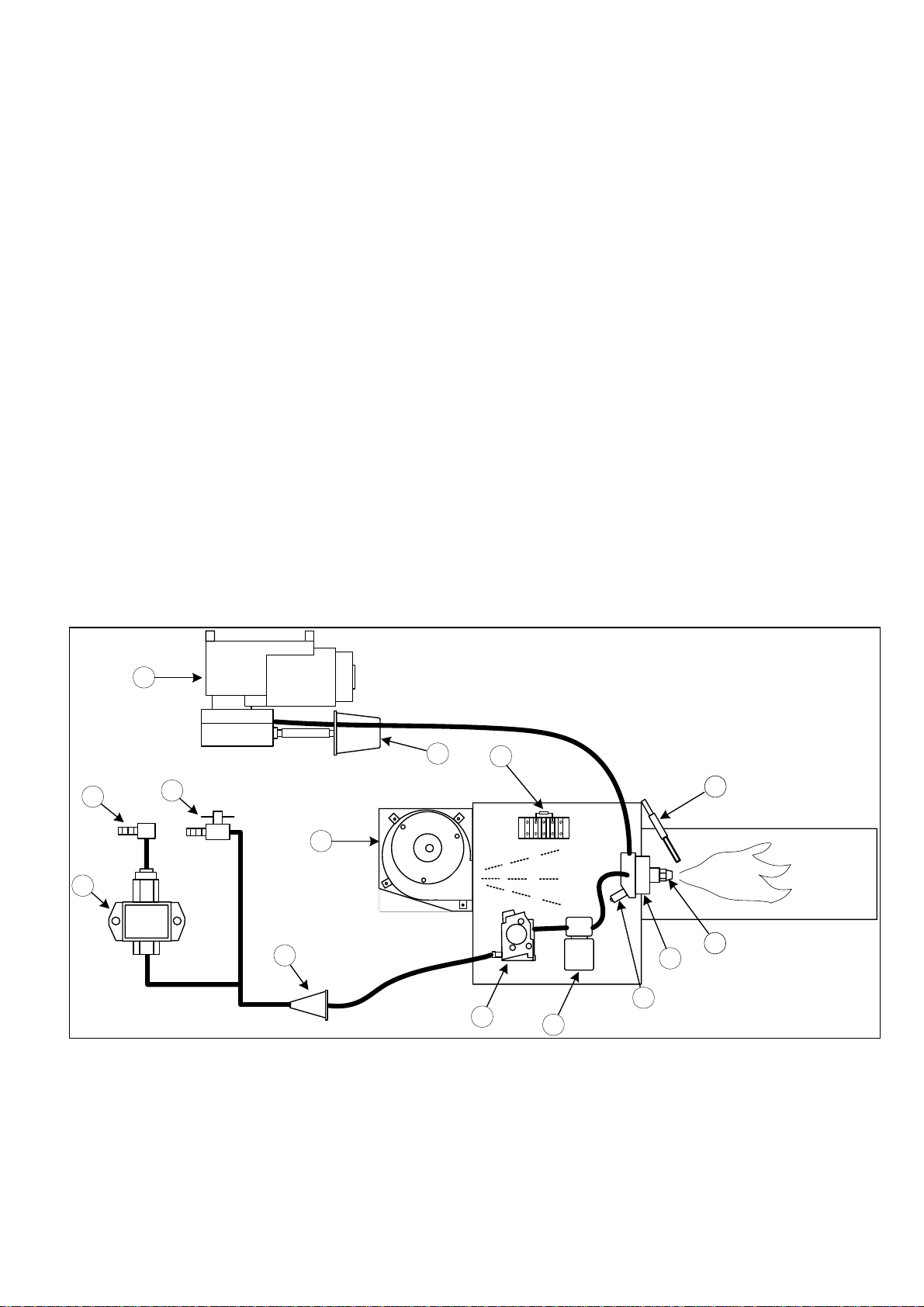

1.2. Burner............................................................................... 6

2. Control Board ........................................................................... 9

3. Troubleshooting .......................................................................13

3.1. Overview ..........................................................................13

3.2. Power On (Green) ..............................................................13

3.3. Burner On .........................................................................13

3.4. V- Service Switch Off .........................................................13

3.5. 9- Remote Switch Off.........................................................13

3.6. <- Heater Cycling (Normal Operation)...................................14

3.7. T- Thermostats Off (Normal Operation).................................14

3.8. 0- Voltage Low or High.......................................................15

3.9. 1- Overheat.......................................................................15

3.10. 2- Fuse Blown................................................................16

3.11. 3- Fuel Pump/Solenoid ....................................................16

3.12. 4- Ignitor ......................................................................16

3.13. 5- Combustion Fan..........................................................17

3.14. 6- Water Pump...............................................................17

3.15. 7- Flame Out..................................................................18

3.16. 8- Compressor ...............................................................19

3.17. )- Bypass Mode..............................................................19

3.18. Water Pump On (Green)...................................................20

3.19. Test Points .....................................................................20

3.20. LCD Readout Remote Panel ..............................................21

3.21. Flame Sensor Module.......................................................21

3.22. Reduced Output ..............................................................22

3.23. Smokey, Smelly Exhaust..................................................22

4. Step-by-step Troubleshooting ..............................................23

4.1. Flame Out.........................................................................23

4.2. Voltage.............................................................................29

5. Servicing the Hurricane SCH25.............................................31

5.1. Indications Service Is Required ............................................31

5.2. Cleaning the Combustion Chamber .......................................32

5.3. Parts Replacements............................................................33

5.3.1. Fuel Solenoid...............................................................33