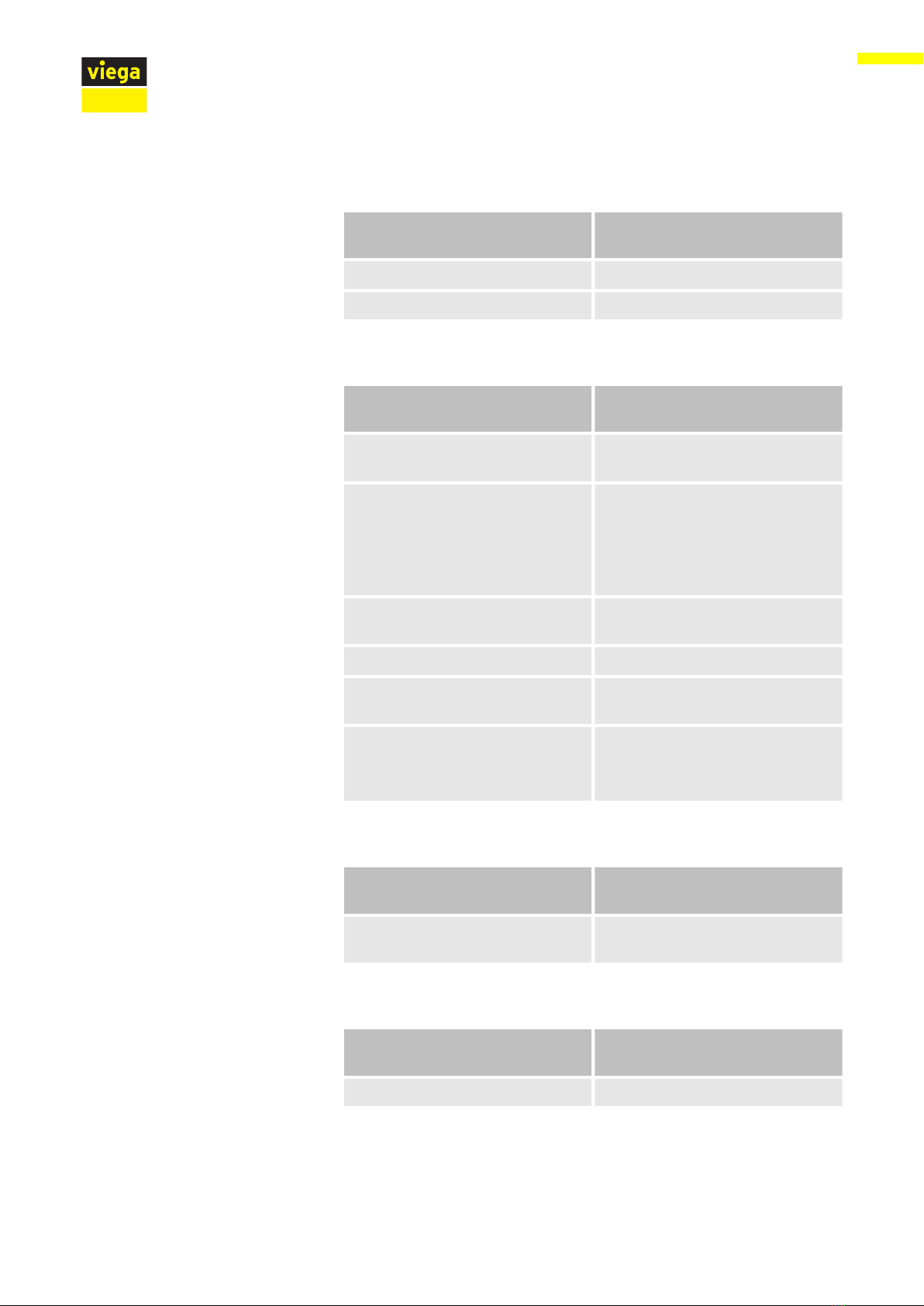

2 Product information

2.1 Standards and regulations

The following standards and regulations apply to Germany / Europe.

National regulations can be found on the relevant web site of your

country at viega.com/standards.

Scope / Notice Regulations applicable in Ger‐

many

Qualification of specialist compa‐

nies

DVGW-Arbeitsblatt GW 301

Qualification and requirements in

the potable water supplier

DVGW-Arbeitsblatt W 1000

Scope / Notice Regulations applicable in Ger‐

many

Planning, execution, operation

and maintenance of potable water

house service connections

DIN EN 805

Planning, execution, operation

and maintenance of potable water

house service connections

DVGW-Arbeitsblatt W 400-1

Planning, execution, operation

and maintenance of potable water

house service connections

DVGW-Arbeitsblatt W 400-2

Planning, execution, operation

and maintenance of potable water

house service connections

DVGW-Arbeitsblatt W 400-3

Planning, execution, modification

and operation of gas house

service connections

DVGW-Arbeitsblatt G 459-2

Planning, execution, modification

and operation of liquid gas instal‐

lations

DVFG-TRF 2012

Planning, execution, modification

and operation of gas house

service connections

DVGW-Arbeitsblatt G 472

Regulations from section: Target group

Regulations from section: Fields of application

Product information

Geopress K repair coupling 6 from 23