HY28-2600-550-M1/USA HY28-2600-550-M1/USA

Standard Hydraulic Power Units Installation and Maintenance Manual

D, H, V-Pak and Custom Power Units

Standard Hydraulic Power Units Installation and Maintenance Manual

D, H, V-Pak and Custom Power Units

9

8

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

United States

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

United States

Supply and Return Connections

Supply and Return Connections

Complete all necessary interconnecting piping

between the power unit and hydraulic actuators. The

line sizes should be determined based on oil ow,

operating pressure, viscosity and allowable pressure

drop between the power unit and point of use. The

exact connection details will depend on how the power

unit was ordered. If the unit was ordered with a PT

block, the top plate will have a block with a“P” and a

“T” stamped on it. The“P” is the pressure connection,

and the “T” is the tank or return connection. If the

unit was ordered with a manifold option, there will be

ports labeled “A” and “B.”These are connections that

normally go directly to the customer’s actuator ports.

The actuator is controlled by valves mounted on the

manifold. These valves could be supplied from the

factory or added by a third party or the customer.

WARNING:

Check to ensure that the proper rated hose or

pipe is used on pressure lines. It is the customer’s

responsibility to select the proper hose or tube

style to ensure safe and reliable performance.

Improper selection of the interconnecting plumbing

can cause serious injury or death. Make sure

you fully understand the requirements for a safe

installation or contact professional assistance.

Make sure vibration and thermal expansion are

considered. Straight tube runs should include

bends to accommodate thermal expansion and

contraction. If the power unit is mounted on a

separate base from the rest of the installation,

exible hose may be required to absorb possible

relative movement.

Important:

One of the key ingredients for good service and long

life from a hydraulic system is cleanliness. Since most

dirt inltrates a hydraulic system during installation,

Parker recommends the following:

1. All open ports on the power unit, cylinders,

etc. must remain plugged with tape or plastic

plugs until just before the hydraulic connections

are made.

2. All interconnecting tubing, pipe or hose should be

clean and free of rust, scale and dirt. The ends of

all connectors should be plugged until just before

they are to be installed in the system.

Start-Up Procedure

Start-Up Procedure

NOTE:

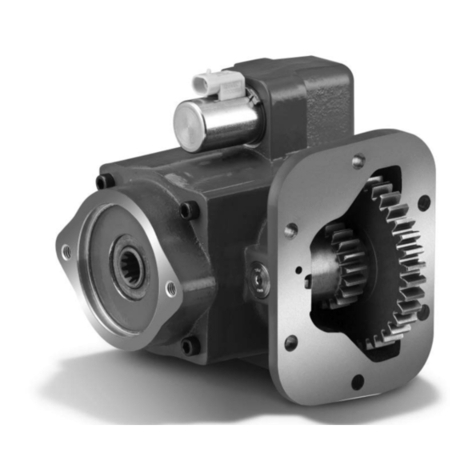

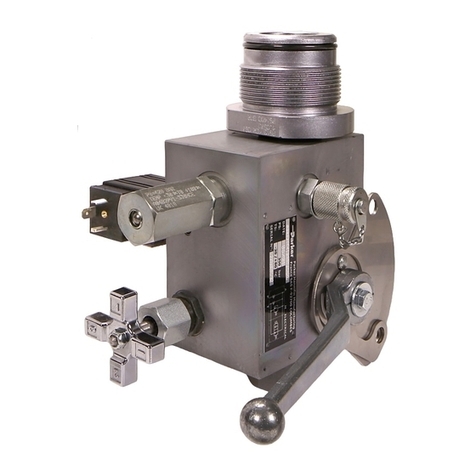

If the power unit has been provided with a variable

displacement pump (V-Pak), the pump case should

be lled with clean oil prior to priming. Located on the

power unit’s top plate, there is a port labeled “Pump

Case.” Remove the plug from this port, ll it with oil

and then replace the plug. See right:

Before proceeding to the rest of the start-up

procedure, wear proper personal protective

equipment. Safety glasses and gloves are the

minimum required items to avoid exposure and

injury from unexpected high-pressure oil leaks.

1. If the system has a standard solenoid controlled

unloading valve, it should be turned o to allow

the system to start up at minimum pressure. A few

special systems have a normally closed unloading

valve, in which case it should be energized to get

low pressure.

2. If the system has been provided with an open

center directional valve, the oil during start-up will

ow directly back to tank when neither solenoid is

energized. This should allow the system to prime

very quickly.

3. All openings in the reservoir such as the ller

breather or access end cover holes must remain

closed during installation.

4. If Teon tape or pipe dope is used, be sure it

doesn’t extend beyond the rst thread of the

pipe tting.

Reservoir Filling

The reservoir must be lled with clean uid through

the ller cap on the reservoir. The type of uid must be

compatible with the seals used on the power unit, and

must comply with the recommendations of the

manufacturers of the component parts. Refer to the

component manufacturer’s catalog for uid requirements.

The cleanliness of the uid going into the reservoir

is very important, and in most cases, even new oil out

of the drum is not adequate. We recommend that any

uid being transferred into the reservoir be done with a

transfer pump with a 10-micron lter installed. Various

Parker oil transfer pumps are available for this purpose.

Additionally, Parker sells pre-cleaned uid called

DuraCleanTM. This uid is clean from the drum and has

additives that resist moisture buildup, reducing varnish

and oxidation.

Cautions About Filling

Power units should be lled while they are not running,

especially if there is an accumulator in the system. If a

system has an accumulator and the oil level is“FULL”

when running, the oil level will likely overow when the

system is turned o.

After the initial ll, re-check the oil level after the

system has been in operation for a few cycles. In

some installations, the actuators and plumbing will

“consume”enough oil that the system will need

another ll to prevent it from running low during the

machine cycle.

Pressure lter manifold

Pressure gage w/ shuto

Relief valve (set higher

than pump compensator

Spare return w/ down

tube 3/4" NPT female

Return lter Temp/level

switch

Pump prell port

(8 to 15 GPM only)

Remote compensator

(set lower than main relief)

Filler breather

3. Fixed volume systems (D and H Paks) will have a

P to T open path if it is equipped with an unloading

option. On V Paks, the unloading option unloads

the pump compensator, not the main pressure line,

therefore additional work to prime the system may

be required.

4. Turn the main relief valve all the way down

(counter clockwise).

5. Jog the pump motor once, and verify that the

pump is rotating in the same direction as the

arrow tag on the motor fan cover. If the direction

is incorrect, reverse any two (2) of the three (3)

motor leads, and re-check the rotation. Most units

are right hand rotation, or clockwise looking down

at the motor fan. If the unit has a rear mount heat

exchanger, you may need to use a small piece

of thin wire or zip tie to“feel” which direction the

motor’s fan is turning.

6. Jog the pump/motor three (3) to six (6) times to

prime the pump and then allow the pump to run

for several minutes at minimum pressure. Check

the piping for any leaks and correct immediately.

(Leaks in ttings and tubing can be the result of

vibration during shipping.)