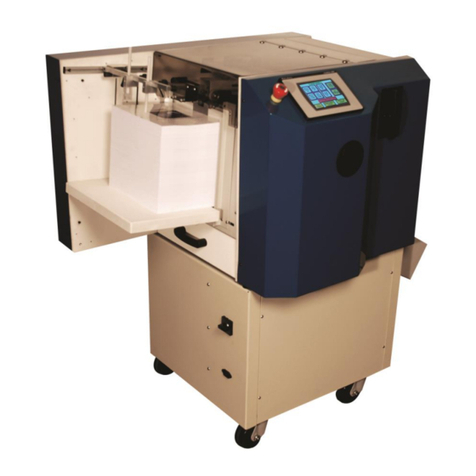

SPECIFICATIONS

CONVEYOR

POWER FD: 105/120 VAC 50/60 HZ FE: 240 VAC 50/60 HZ

MAIN FUSE FD 4040: 10 AMP FE 4040: 7 AMP

FD 4060: 15 AMP FE 4060: 10 AMP

SECONDARY FUSE FD 4040: 3 AMP FD 4040:

POWER CONSUMPTION

CONVEYOR @ MAX SPEED NO LOAD FD 4040: .56 AMP FE 4040:

FD 4060: FE 4060:

CONVEYOR @ MAX SPEED NO LOAD W/ ONE

FAN

FD 4040: .76 AMP FE 4040:

FD 4060: FE 4060:

CONVEYOR @ MAX SPEED NO LOAD W/ BOTH

FANS

FD 4040: .96 AMP FE 4040:

FD 4060: FE 4060:

CONVEYOR @ MAX SPEED NO LOAD W/ BOTH

FANS AND DRYER

FD 4040: 6.19 AMP FE 4040:

FD 4060: FE 4060:

BELT SPEED VARIABLE 30 TO 350 FT PER MINUTE

FAN C.F.M. 170 C.F.M. EACH

HEIGHT ADJUSTABLE 28” TO 35” FLOOR TO TRANSPORT BELT

LENGTH 65”

WIDTH 14”

DROP TRAY ADJUSTABLE 5.2’, 7.2”, 9.2” & 11.2” TRANSPORT BELT TO STACKING

SURFACE

WEIGHT 130 LBS (INCLUDES ACCESSORIES)

1

UNPACKING

INSPECT FOR SHIPPING DAMAGE, MISSING PARTS AND PROPER OPERATION. REPORT SHIPPING DAMAGE

TO THE CARRIER IMMEDIATELY. SAVE THE SHIPPING CARTONS AND MATERIALS IN CASE THEY ARE NEEDED

TO FILE A SHIPPING CLAIM OR FOR FUTURE SHIPPING USE.

1. Check the outside of the carton for visible damage. Make note of any damage on the carrier’s receiving report.

2. Open the carton.

3. Carefully remove the carton contents and inspect the unit for paint and structural damage.

4. Carefully check for missing parts. If damage or missing parts are noted, contact your Sales Representative immedi-

ately. Save cartons and packing materials. They may be required to substantiate a damage claim or to return a damaged

unit.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920