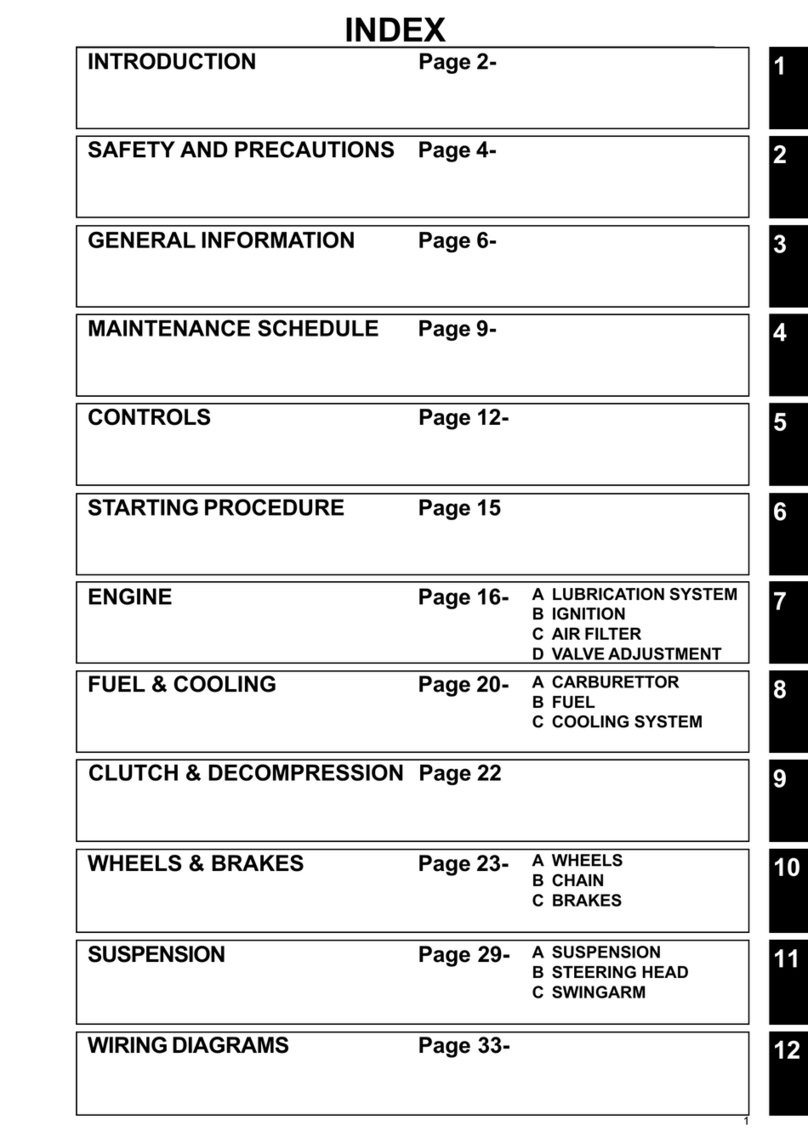

GENERAL INFORMATION

6

3

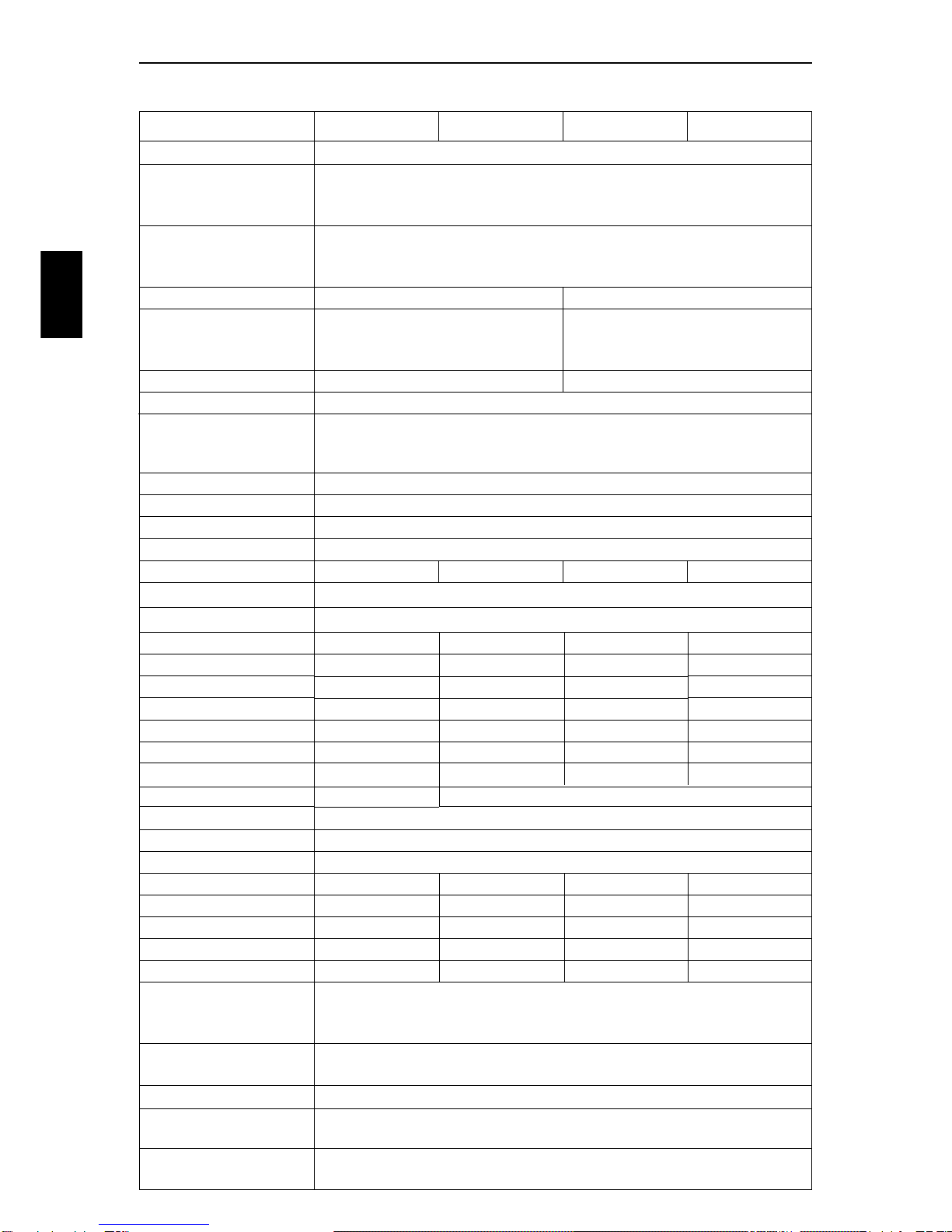

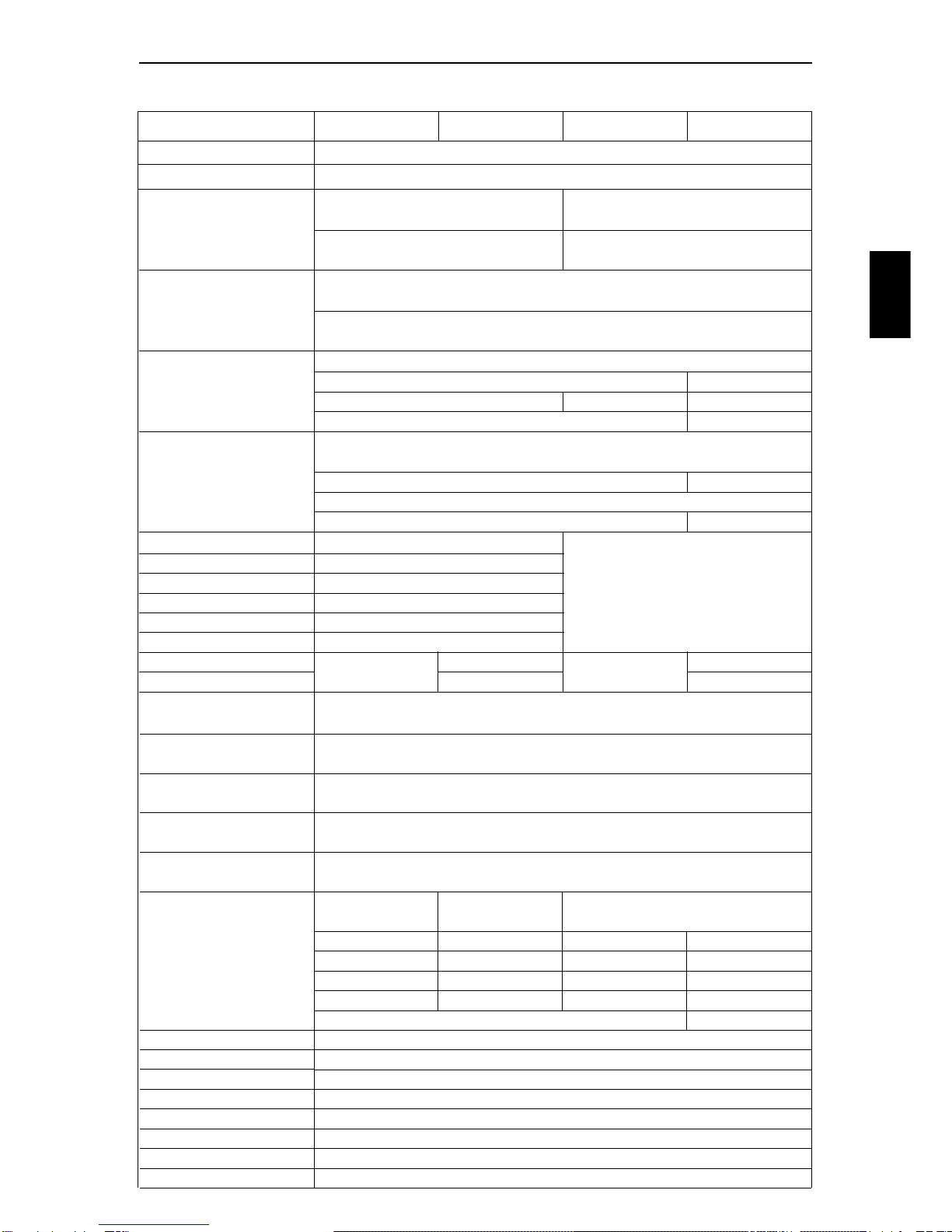

3SPECIFICATIONS

ENDURO MOTOCROSS ELDURO DESERT (FX)

Liquid cooled, 4-stroke single cylinder, SOHC-4 valves

400-models:399cc / Bore 92,0 mm x Stroke 60,1 mm

501-models:501cc / Bore 95,0 mm x Stroke 70,7 mm

600-models:595cc / Bore 95,0 mm x Stroke 84,0 mm

400-models:12,0:1

501-models:11,8:1

600-models:11,6:1

One automatic system activated by the

camshaft, oneactivatedbythekickstarter

and one operated by a manual lever

Fully automatic system activated by

the camshaft plus one operated by a

manual lever

Kick starter Electrical- and kick starter

2 mm ± 1 mm 2 mm ± 1 mm

Intake and Exhaust:0,10 mm

SUBJECT/MODEL

Engine type

Displacements

Compression ratio

Decompression system

Start system

Decomp.cable clearance

Valve clearance Orbit oilpump and reedvalve controlled lubrication

Oil-cooled piston and connecting rod

Replaceable micro filter and washable oil screen

1,0 Litre Synthetic SAE 5W-50 API SG/CF (minimum SAE 15W-50)

SEM, CDI, DFC™;Dynamic Force Control

Lubrication

Engine oil

Ignition NGK DCPR8E / 0,7 mmSpark plug / gap 1,3 litre of 50% Anti-freeze, with corrosion inhibitor, and 50% waterCoolant 12V / 70 + 70 W Not available 12 V / 70 + 70W 12 V / 70 + 70 WAlternator

Inox steel pipes, 2 into 1 collector, Aluminium/Inox silencer (FCTitanium/Inox)

US-versions except FC models equipped with spark arrester

Exhaust system

Fuel capacity All models except FR 600 E:9 litres

FR 600 E: 25 litres

520 O-ring chain

15/42 - 2,800

15/42 - 2,800

13/48 - 3,692 13/48 - 3,692 13/48 - 3,692

15/48 - 3,200 (15/48 - 3,200) 15/48 - 3,200 15/48 - 3,200

15/48 - 3,200 (15/42 - 2,800) 15/48 - 3,200 15/48 - 3,200

400-models:Dellorto PHM 38

501- & 600-models:Dellorto PHM 40

Dual Sport USA - FS 600:Edelbrock Qwiksilver 38

All models except FR 600 E:Single foam filter

FR 600 E:Double foam filters

RON 98 (octane), unleaded

29/78 - 2,690

Spur gears

Clutch hydraulic oil

Secondary transmission

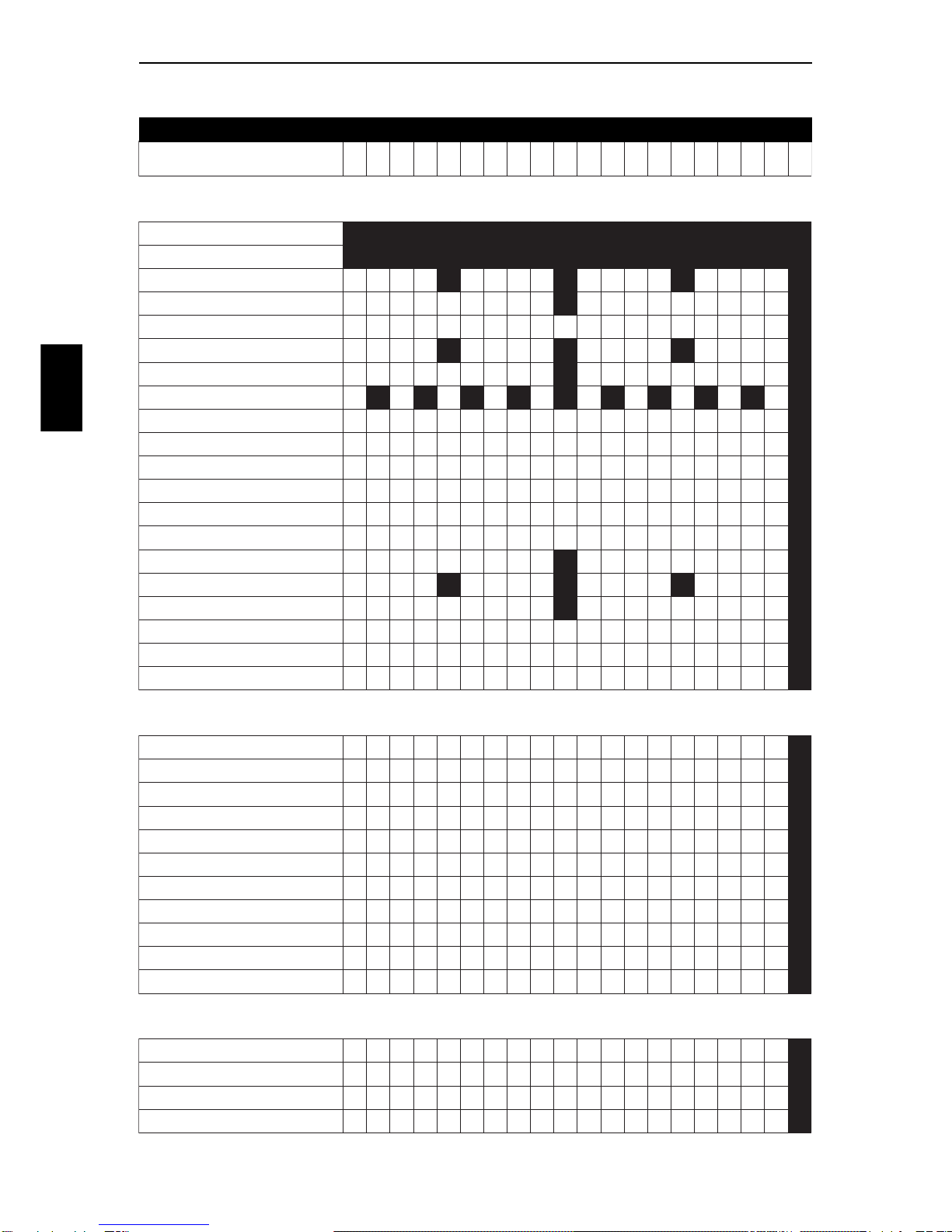

Ratios 501/4-speed

600/4-speed

400/6-speed

501/6-speed

600/6-speed

Carburettor

(std. jetting see page 8)

Air filtration

Fuel

Ratio

Primary transmission

Hydraulic, 7 friction- and 8 mating plates in oil bathClutch

Gearbox

Ratios 1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Mineral oil SAE 2-7W

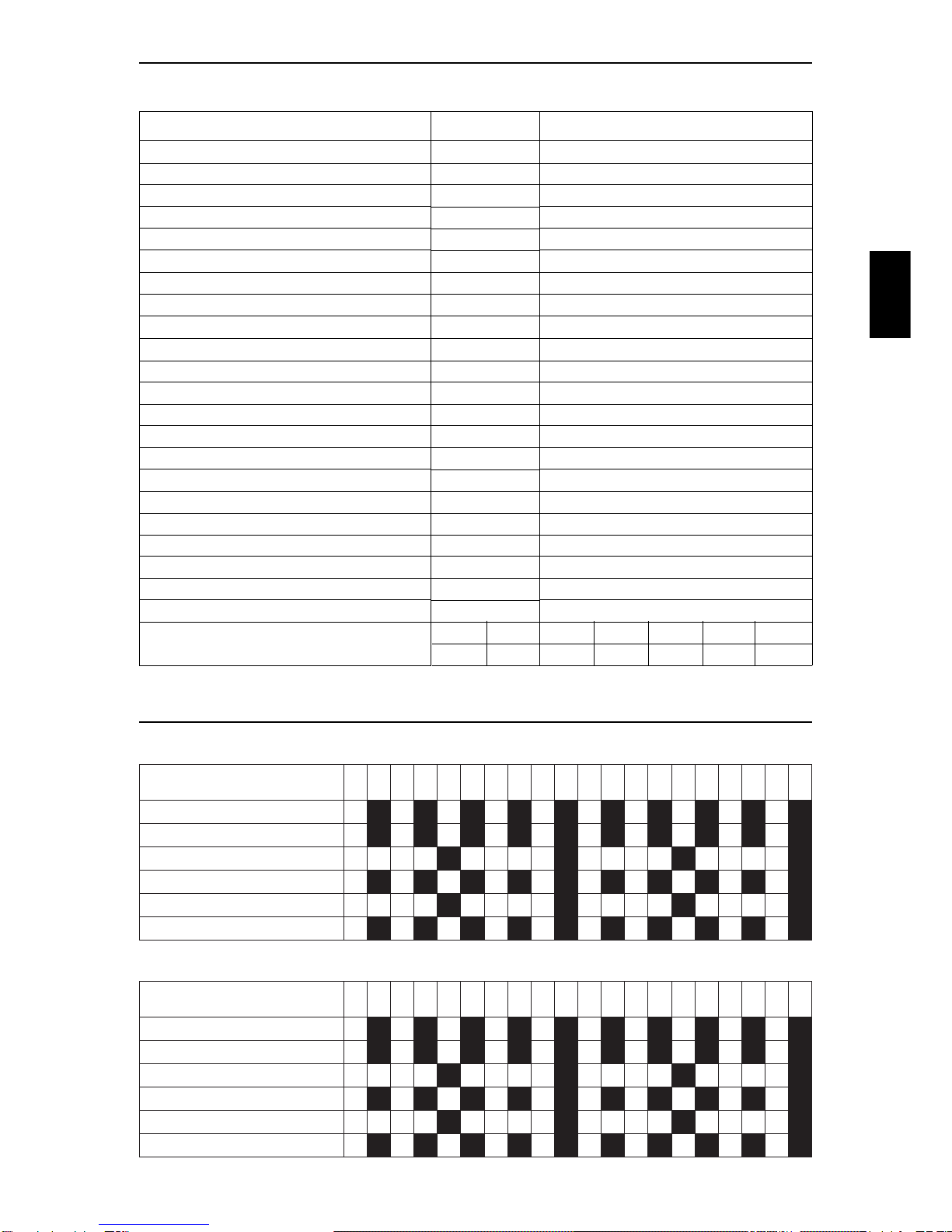

6-speedWR 4 or (6)-speed CR 6-speedWR 6-speed S-WR

15/32 - 2,133 13/34 - 2,615 15/32 - 2,133

*17/30 - 1,765 18/28 - 1,555 17/30 - 1,765 18/28 - 1,555

*20/27 - 1,350 20/25 - 1,250 20/27 - 1,350 20/25 - 1,250

*23/24 - 1,043 23/24 - 1,043 23/24 - 1,043 23/24 - 1,043

25/22 - 0,880 (24/22 - 0,917) 25/22 - 0,880 25/22 - 0,880

*FC 4-speed WR

*13/34 - 2,615

(25/21 - 0,840) 27/20 - 0,741 27/20 - 0,741

27/20 - 0,741