GENERAL INFORMATION

6

3

3

SPECIFICATIONS

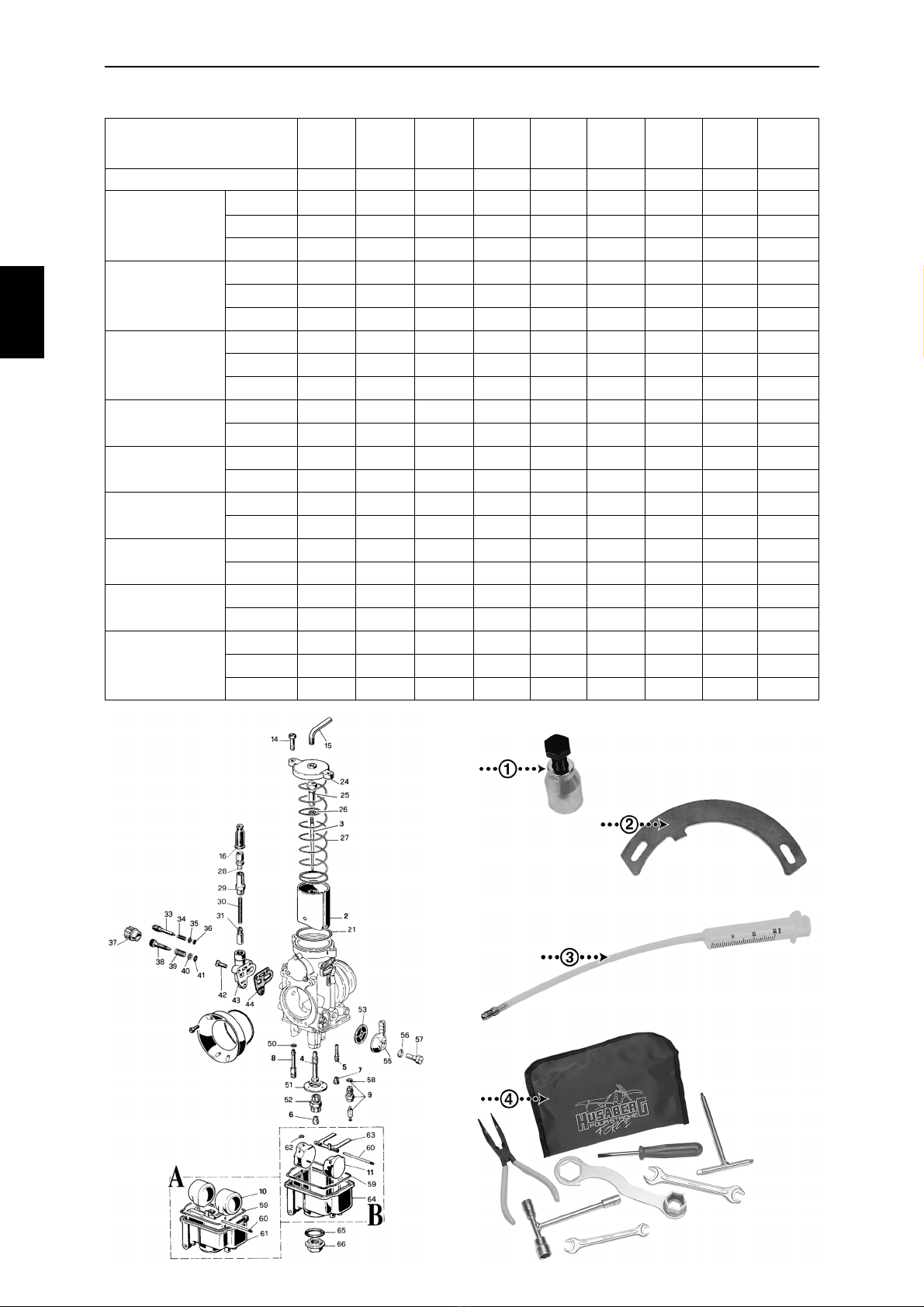

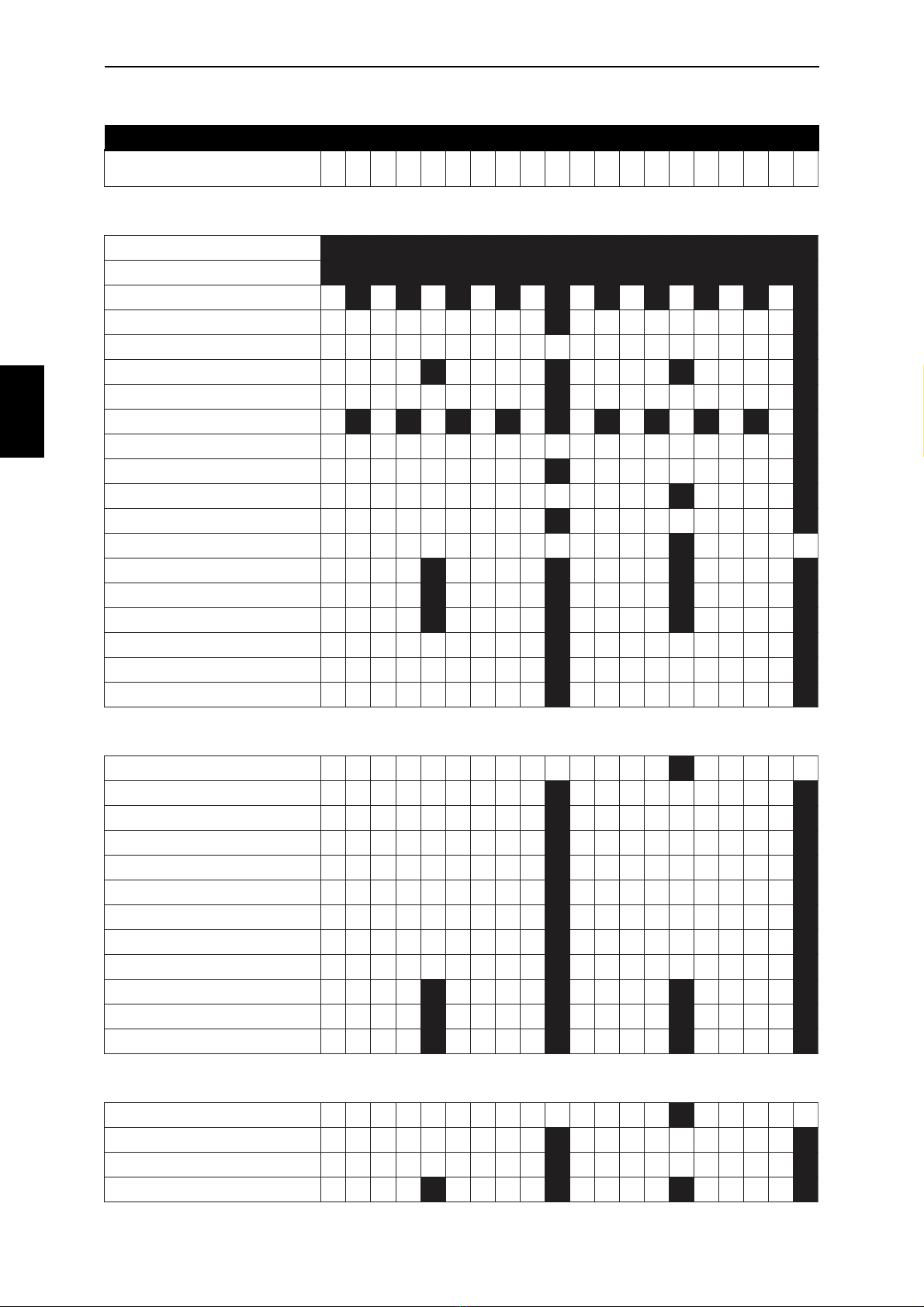

SUBJECT/MODEL FE 400 e FE 501 e FE 650 e FS 400 e FS 650 e FS 400 c FS 650 c FC 470/6 FC 550/4 FC 550/6 FC 470 e FX 470 e FX 650 e

Displacement 399cc 501cc 644cc 399cc 644cc 399cc 644cc 472cc 550cc 550cc 472cc 472cc 644cc

Bore x Stroke (mm) 92 x 60,1 95 x 70,7 100 x 82,0 92 x 60,1 100 x 82,0 92 x 60,1 100 x 82,0 100 x 60,1 100 x 70,0 100 x 70,7 100 x 60,1 100 x 60,1 100 x 82,0

Compression ratio 12,5:1 11,8:1 11,0:1 12,5:1 11,0:1 12,5:1 11,0:1 12,4:1 12,7:1 12,7:1 12,4.1 12,4:1 11,0:1

Start system Electrical and kick-starter Kick-starter Electrical and kick-starter

Decompression system Three separate ones; one activated by the kickstart lever, one activated by the camshaft and one activated by a lever on the handlebar

Decomp. cable clearance 2mm ± 1mm / 0,08 in ± 0,04 in.

Engine Liquid cooled single cylinder 4-stroke, SOHC-4 valves, counter balancer

Valve clearance Intake and Exhaust: 0,10mm / 0,004 in.

Lubrication system Orbit oil pump and reed valve controlled. High pressure jet spray of piston and connecting rod, pressure lubrication of connecting rod bearing and rocker arms. Oil screen and micro filter

Engine oil 1,0 Litre Synthetic SAE 5W-50 API SG/CF (minimum SAE 10W-50)

Ignition system SEM Dynamic Force Control, DFC™, Dual Ignition Curves; High & Low. A load sensitive digital system with six sensors

Spark plug - Spark plug gap NGK DCPR8E - 0,6 mm / 0,025 in.

Alternator 12 V 70 + 70 W Not available 12 V 70 + 70 W

Air intake system Single foam filter

Carburettor (DELLORTO) PHM 38 PHM 40 PHM 40 PHM 38 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40

Fuel RON 98 (octane), unleaded

Exhaust system Chrome plated steel pipes, 2 into 1 collector, Aluminium/steel silencer. USA versions, except FC and FSc models, equipped with spark arresters

Coolant 1,3 Litre of 50% Anti-freeze, with corrosion inhibitor, and 50% water

Clutch Hydraulic, 7 friction- and 8 mating plates in oil bath

Clutch hydraulic oil Mineral oil SAE 2-7W

Wear limit clutch discs 19,6 mm / 0,772 in.

Primary transmission Spur gears, ratio 29/78 - 2,690

Gearbox 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed CR 4-speed 6-speed CR 6-speed CR 6-speed 6-speed

Ratios 1st: 14/33 - 2,357 2nd: 17/30 - 1,765 3rd: 19/26 - 1,368 4th: 23/25 - 1,087 5th: 24/22 - 0,917 6th: 27/20 - 0,741 (6th CR: 25/21-0,840)

Secondary transmission D.I.D. 520 O-ring chain

Sprockets front/rear 13/48 15/48 15/42 15/42 15/42 15/42 15/42 13/42 15/42 15/48 13/48 13/48 15/42

Wear limit drive chain 272 mm - 18 chain reels (tensioned, center distance between reels)

Frame Heat treated BTR / 25CrMo4 steel

Caster 28,5°

Weight (dry) 109,8 kg 110,1 kg 110,9 kg 111,9 kg 113,1 kg 105,7 kg 106,8 kg 103,5 kg 103,5 kg 103,9 kg 109,6 kg 109,6 kg 110,4 kg

242 lb. 243 lb. 244 lb. 247 lb. 249 lb. 233 lb. 235 lb. 228 lb. 228 lb. 229 lb. 242 lb. 242 lb. 243 lb.