3

Foreword

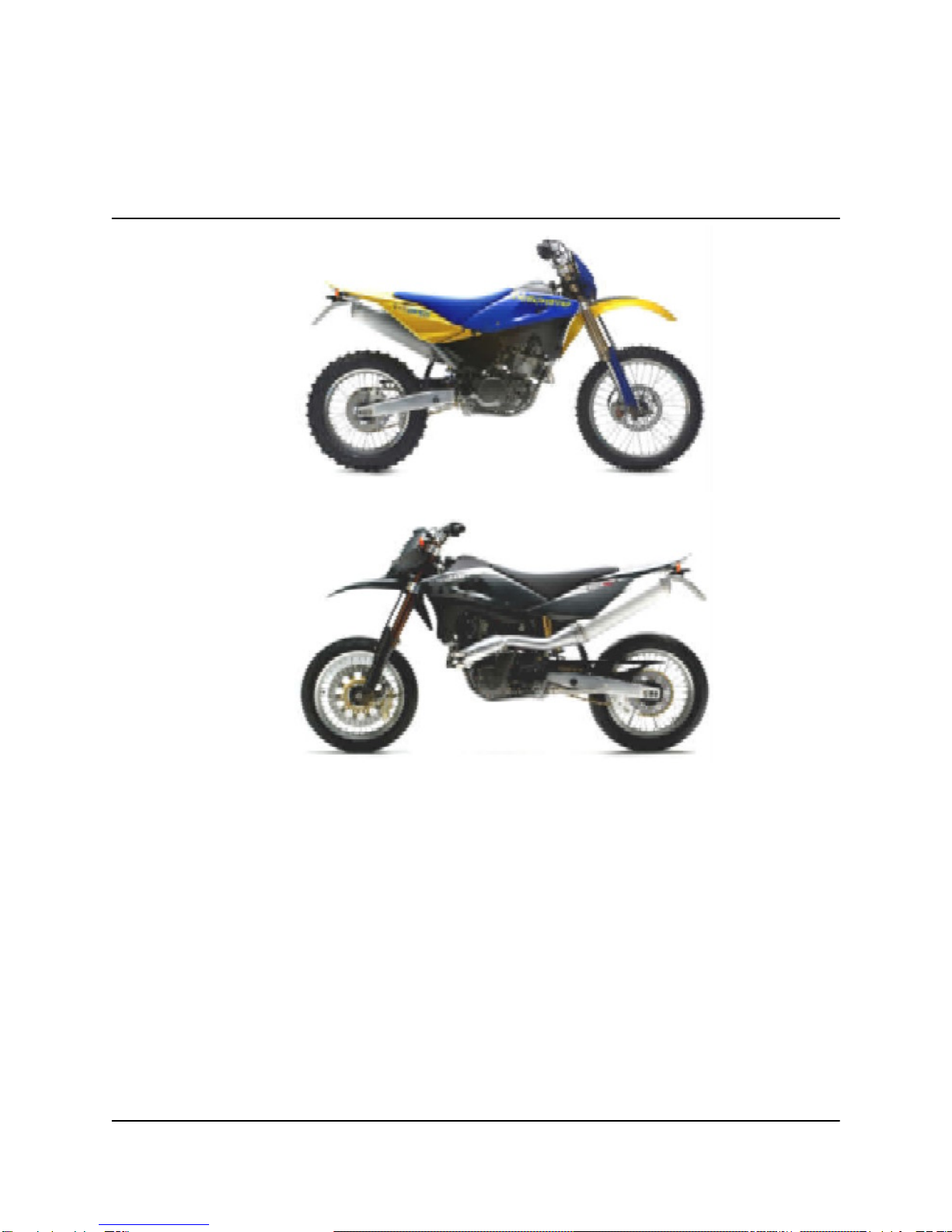

This publication intended for HUSQVARNA Workshops has been prepared for the purpose of helping the authorized personnel in

the maintenance and repair work of the motorcycles herewith dealt with. The perfect knowledge of the technical data contained

herein is essential for a more complete professional training of the operator.

The paragraphs have been completed with schematic illustrations evidencing the subject concerned, in order to enable a more

immediate understanding.

This manual contains information with particular meanings:

Accident prevention rules for the operator and for the personnel working near by.

Possibility of damaging the vehicle and/or its components.

Additional information concerning the operation under way.

Useful suggestions

HUSQVARNA suggests, in order to prevent troubles and in order to have an excellent final result, to generically comply with the

following instructions:

in case of repair work, weigh the impressions of the Customer who complains about the improper operation of the motorcycle,

and formulate proper clearing questions about the symptoms of the trouble.

detect clearly the cause of the trouble. This manual gives the theoretical bases which however shall be integrated by the per-

sonal experience and by the attendance to training courses periodically organized by HUSQVARNA.

rationally plan the repair work in order to prevent dead time as for instance procurement of spare parts, tool preparation, etc.

reach the component to be repaired and perform only the required operations. In this connection, it will be useful to consult the

disassembly sequence contained in this manual.

1 Always replace the seal rings and split pins with new components.

2 When loosening or tightening nuts or bolts, always start from the bigger ones or from the center. Lock at the prescribed torque

wrench setting following a crossed run.

3 Always earmark the components or positions which could be mistaken one for another at the time of assembly.

4 Use original HUSQVARNA spare parts and the lubricants of the recommended brands.

5 Use special tools, where specified.

6 Consult the Service Bulletins as they may contain up-dated adjustment data and repair methodologies.