2

General recommendations

Bear in mind:

!Do not start the machine without making sure the

cutting attachment and all the safety features are

tted and working properly.

! Do not touch hot components, e.g. the mufer before

it has cooled sufciently to avoid burns.

! Avoid getting petrol or oil on your skin or in your

mouth.

Use a barrier cream on your hands. This reduces the

risk of infection and makes dirt easier to wash away.

Long term contact with engine oil can represent a

health hazard.

! Never start the engine indoors. Exhaust fumes are

poisonous! They contain carbon monoxide, an

odourless, poisonous and highly dangerous gas.

! Wipe up oil spills from the oor immediately to avoid

slipping.

! Do not use tools that are worn or t badly, for example

on nuts and screws.

+ Always work on a clean bench.

+ Always work logically to ensure all parts are tted

correctly and that nuts and screws are tightened.

+ Use special tools where recommended to be able to

carry out the work correctly.

The workshop used to carry out repairs must be equipped with

safety devices in accordance with local directives.

No one may carry out repairs without having read and

understood the contents of this workshop manual.

Thisworkshopmanualcontainsthefollowingboxesinrelevant

places.

WARNING!

The warning box warns of the risk of personal

injury if the instructions are not followed.

!

NOTE!

This box warns of damage to material if the

instructions are not followed.

The machine is type approved for safety in accordance with

applicable legislative demands with the equipment specied

in the operator’s manual. The assembly of other equipment or

accessoriesorsparepartsnotapprovedbyHusqvarnacanresult

in the failure to meet these safety demands and that the person

carrying out assembly bears responsibility for this.

Fire hazard

Handle petrol with respect, as it is extremely inammable.

Never refuel while the engine is running.

Do not smoke and ensure there are no open ames or sparks

in the vicinity.

Never start the engine if the machine is leaking fuel or if there

has been a spillage when refuelling. Allow the remaining fuel

to evaporate rst.

Make sure there is a working re extinguisher close at hand.

Do not try to extinguish a petrol re with water.

Poisonous fumes

When using cleaning agents, read the instructions carefully.

Ensure there is good ventilation when handling petrol and

other volatile uids.

The engine’s exhaust fumes are poisonous. Test run the

engine outdoors.

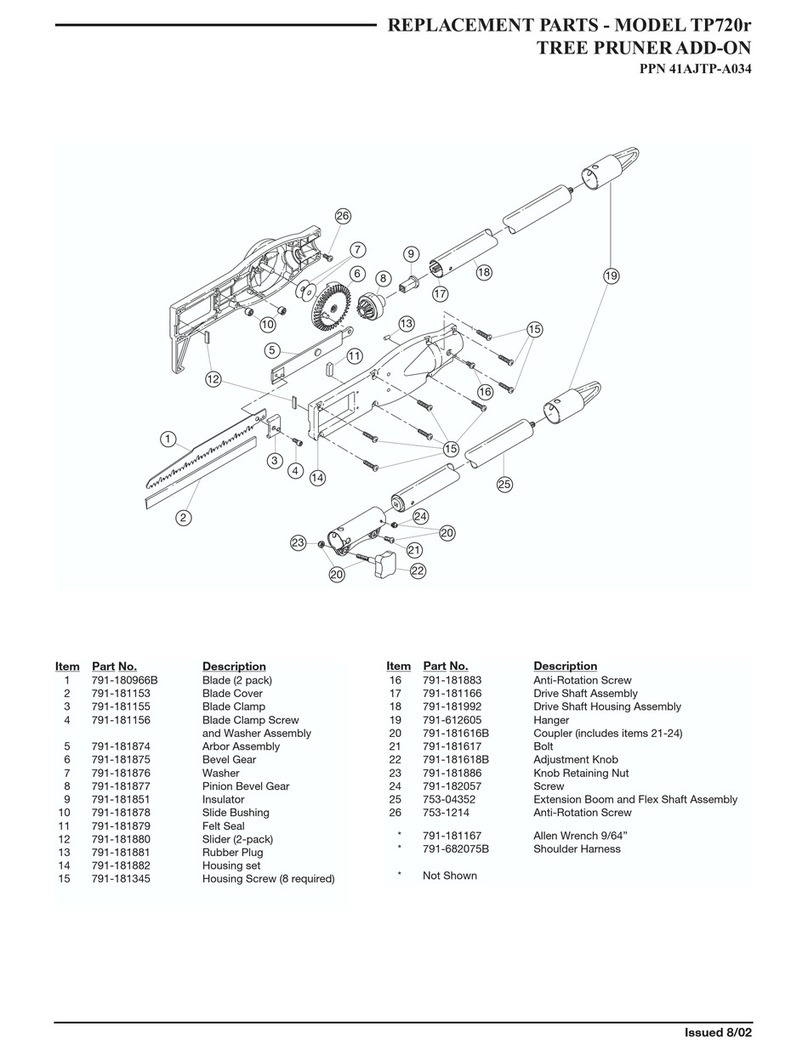

Special tools

Some of the work described in this workshop manual requires

special tools. In each section where this is necessary there is

a picture of the tool and an order number.

We recommend the use of special tools in order to avoid

personal injury and expensive damage to parts in question.

Contact faces and gaskets

Ensure all sealed surfaces are clean and free from gasket

residue. When cleaning use a tool that will not damage

the contact face. Any scratches or unevenness should be

removed using a at ne cut le.

Sealing rings

Always replace a sealing ring that has been dismantled. The

delicate sealing lip can be easily damaged resulting in poor

sealing ability. The area that the seal is designed to make

airtight must also be completely undamaged.

Lubricate the sealing lip with grease before it is tted and

ensure that it is not damaged e.g. by shoulders and splines

on a shaft. Use tape or a conical sleeve as protection.

It is important that the sealing ring faces in the right direction

for it to function as intended.