C2X-XGEP

Technical Data Sheet

P/N 0466003_F

NSF®Certified

March 2008

We reserve the right to change or revise specifications

and product design in connection with any feature of

our products. Such changes do not entitle the buyer to

corresponding changes, improvements, additions or

replacements for equipment previously sold or shipped.

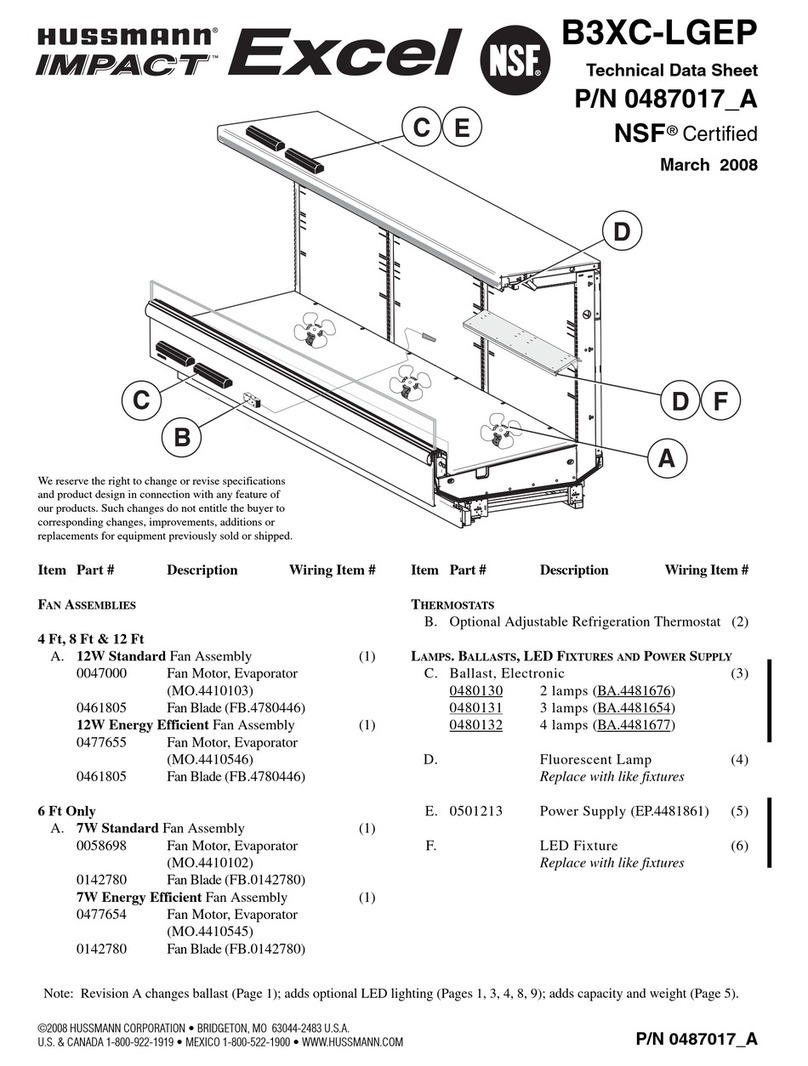

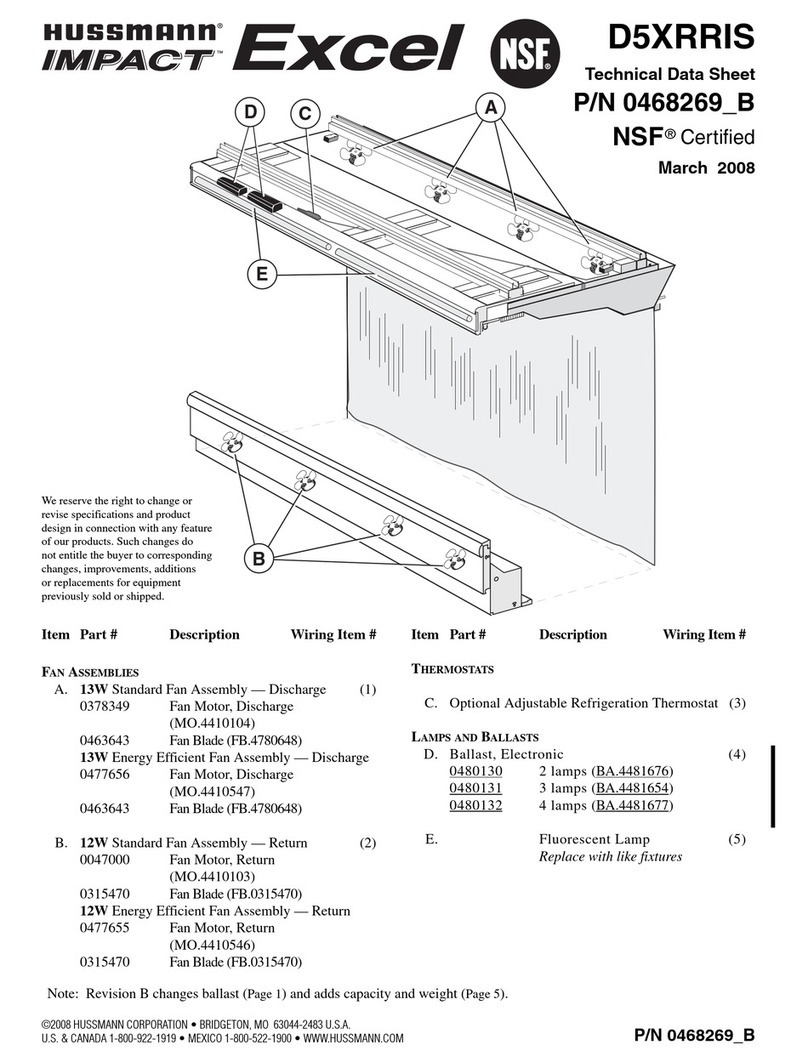

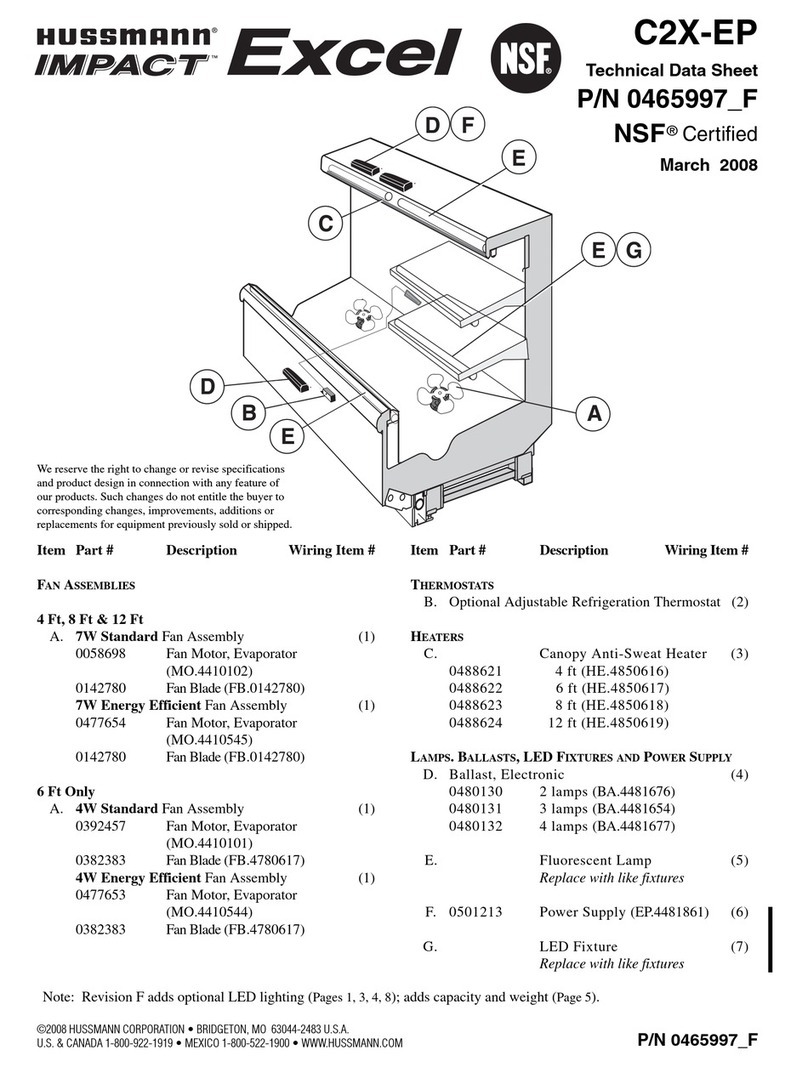

Item Part # Description Wiring Item #

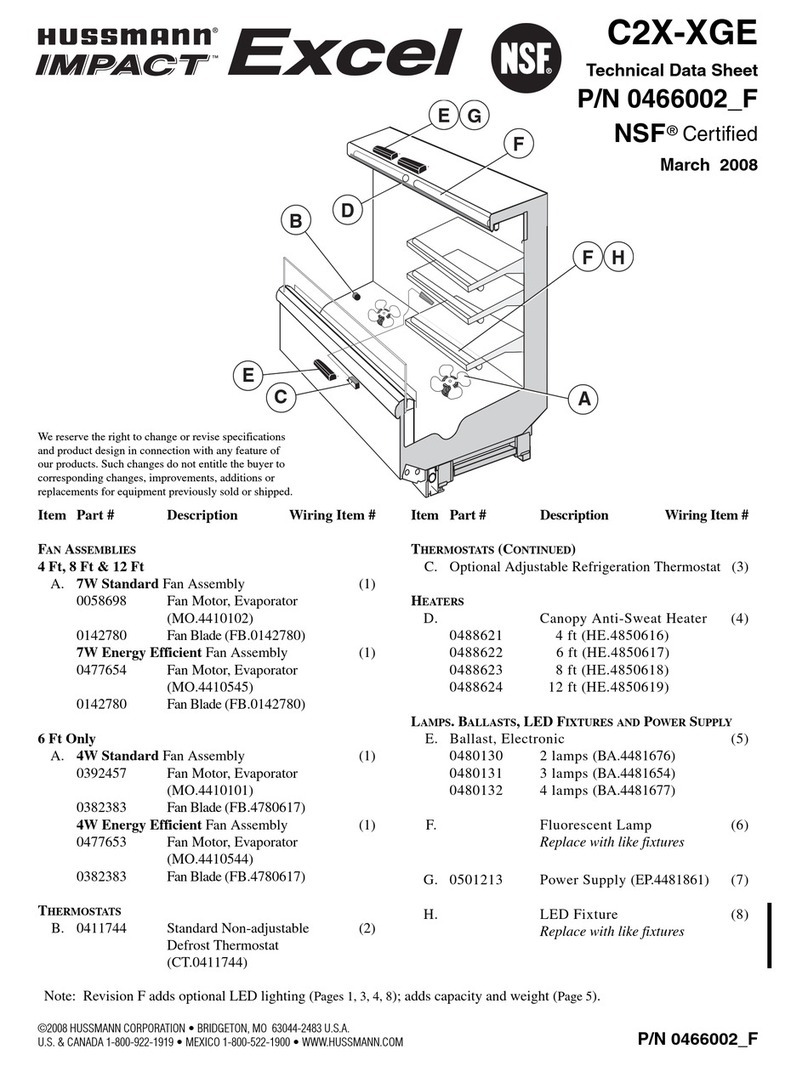

FAN ASSEMBLIES

4 Ft, 8 Ft & 12 Ft

A. 7W Standard Fan Assembly (1)

0058698 Fan Motor, Evaporator

(MO.4410102)

0142780 Fan Blade (FB.0142780)

7W Energy Efficient Fan Assembly (1)

0477654 Fan Motor, Evaporator

(MO.4410545)

0142780 Fan Blade (FB.0142780)

6 Ft Only

A. 4W Standard Fan Assembly (1)

0392457 Fan Motor, Evaporator

(MO.4410101)

0382383 Fan Blade (FB.4780617)

4W Energy Efficient Fan Assembly (1)

0477653 Fan Motor, Evaporator

(MO.4410544)

0382383 Fan Blade (FB.4780617)

THERMOSTATS

B. Optional Adjustable Refrigeration Thermostat (2)

Item Part # Description Wiring Item #

HEATERS

C. Canopy Anti-Sweat Heater (3)

0488621 4 ft (HE.4850616)

0488622 6 ft (HE.4850617)

0488623 8 ft (HE.4850618)

0488624 12 ft (HE.4850619)

LAMPS. BALLASTS, LED FIXTURES AND POWER SUPPLY

D. Ballast, Electronic (4)

0480130 2 lamps (BA.4481676)

0480131 3 lamps (BA.4481654)

0480132 4 lamps (BA.4481677)

E. Fluorescent Lamp (5)

Replace with like fixtures

F. 0501213 Power Supply (EP.4481861) (6)

G. LED Fixture (7)

Replace with like fixtures

©2008 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900 • WWW.HUSSMANN.COM

Note: Revision F adds optional LED lighting (Pages 1, 3, 4, 8); adds capacity and weight (Page 5).