Rev.0106

7

Refrigeration

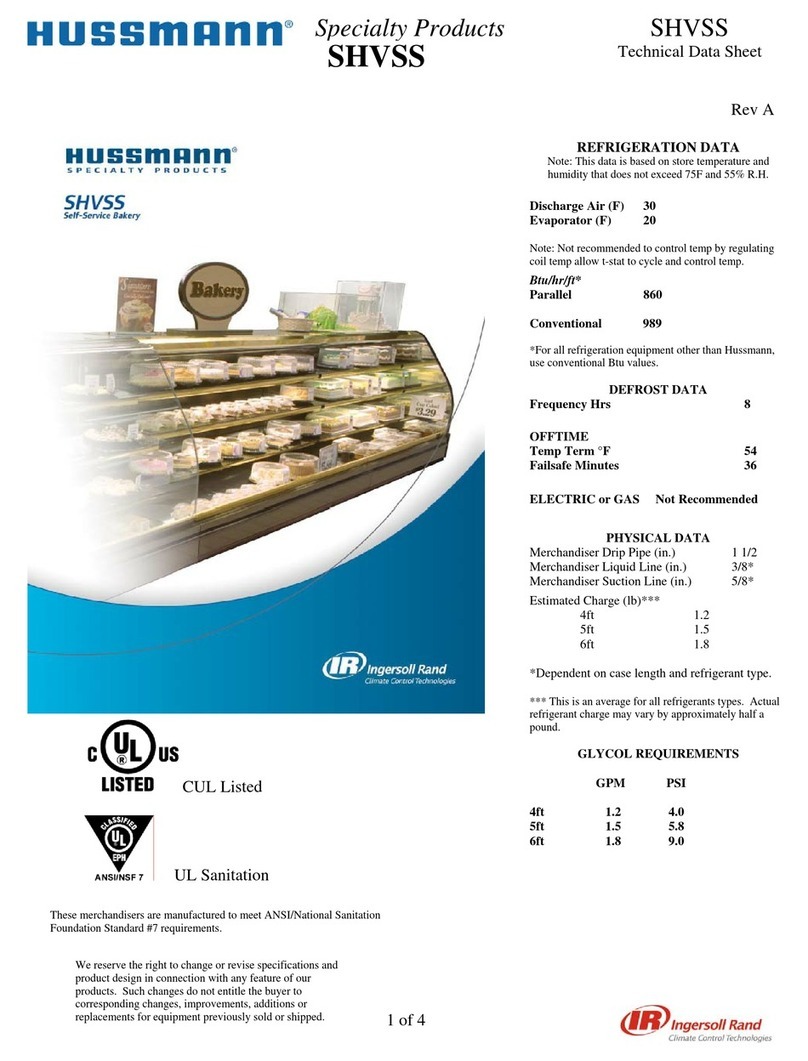

REFRIGERANTTYPE

The standard refrigerant will be R-22 unless otherwise

specified on the customer order. Check the serial plate

on the case for information.

PIPING

The refrigerant line outlets are located under the fixture

at the left hand end when viewed from the back.Insulate

the suction lines to prevent condensation leakage.

REFRIGERATION LINES

LIQUID SUCTION

3/8" O.D. 5/8" O.D.

NOTE: The standard coil is piped at 5/8" (suction);

however, the store tie-in may vary depending on

the number of coils and the draw the case has.

Depending on the case setup, the connecting point

in the store may be

5/8", 7/8", or 11/8". Refer to the particular case you

are hooking up.

Refrigerant lines should be sized as shown on the refrig-

eration legend furnished by the store.

Install P-traps (oil traps) at the base of all suction line ver-

tical risers.

Pressure drop can rob the system of capacity.To keep the

pressure drop to a minimum,keep refrigerant line run as

short as possible,using the minimum number of elbows.

Where elbows are required,use long radius elbows only.

CONTROL SETTINGS

See the “Case Specs” section of this guidebook for the

appropriatesettingsforyourmerchandiser.Maintain these

parameters to achieve near constant product tempera-

tures.Producttemperatureshould be measuredfirst thing

in the morning, after having been refrigerated overnight.

For all multiplexing, defrost should be time terminated.

Defrost times should be as follows: OFF CYCLE - One

time daily for 110 minutes.The number of defrosts per

day shouldneverchange.The duration ofthe defrostcycle

may be adjusted to meet conditions present at your loca-

tion.

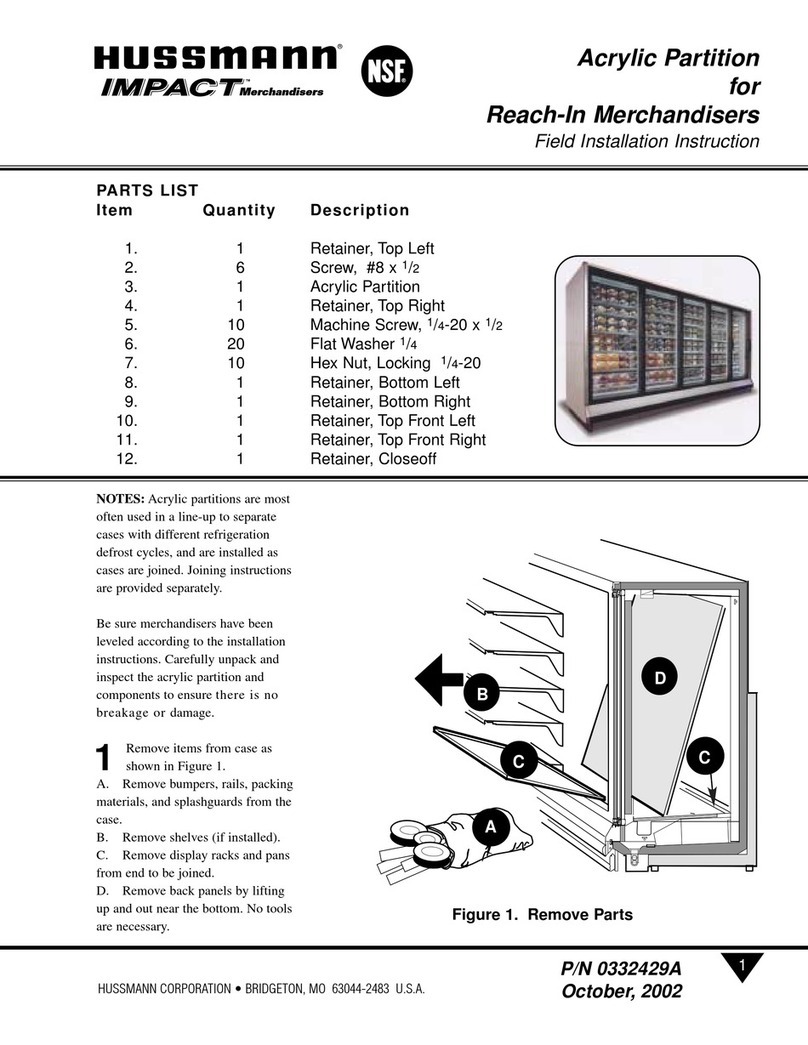

ACCESS TOTXVALVES & DRAIN LINES

MECHANICAL - Remove product from the case. Remove

product racks (if applicable).Remove refrigeration and drain

access panels (labeled).TX valve (mechanical only) and drain

are located under each access panel at end of the case.

ELECTRONIC -The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s).

ELECTRONIC EXPANSIONVALVE (OPTIONAL)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and con-

troller manufacturersinformation sheet. Sensors forelec-

tronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers

will be located in the electrical raceway or under the case

THERMOSTATIC EXPANSIONVALVE LOCATION

AnAlco balanced port expansion valvemodel isfurnished

as standard equipment,unless otherwise specified by cus-

tomer.There is one expansion valve located on the right

sideof each evaporation coil underthebottom deck pans.

EXPANSIONVALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed the evapo-

rator. Before attempting any adjustments,make sure the

evaporatoriseitherclearorvery lightlycoveredwithfrost,

and that the fixture is within 10°F of its expected operat-

ing temperature.

MEASURINGTHE OPERATING SUPERHEAT

1. Determinethesuctionpressurewithanaccurate

pressuregaugeattheevaporatoroutlet.

2. Fromarefrigerantpressure temperaturechart,

determinethe saturation temperatureat the

observedsuction pressure.

3. Measurethe temperatureofthe suctiongas at the

thermostaticremotebulb location.

4. Subtractthe saturationtemperatureobtainedinstep

No.2fromthetemperaturemeasuredinstepNo.3.

3. The differenceissuperheat.

5. Set thesuperheat for5°F- 7°F.

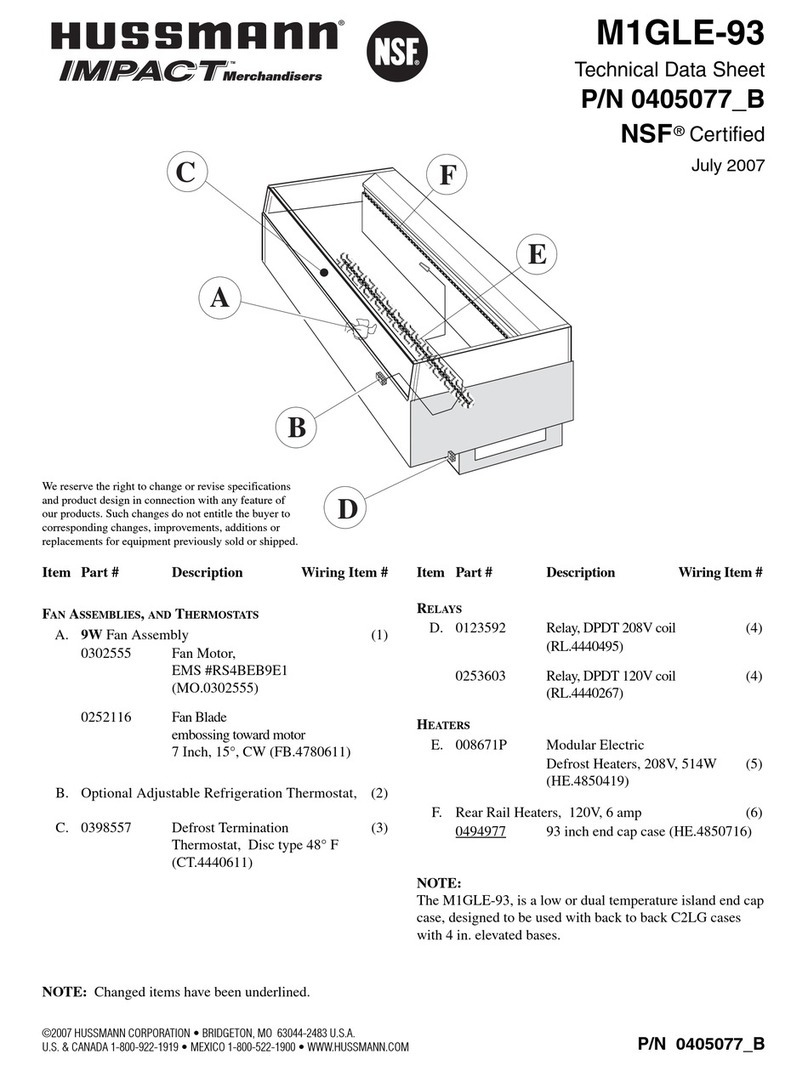

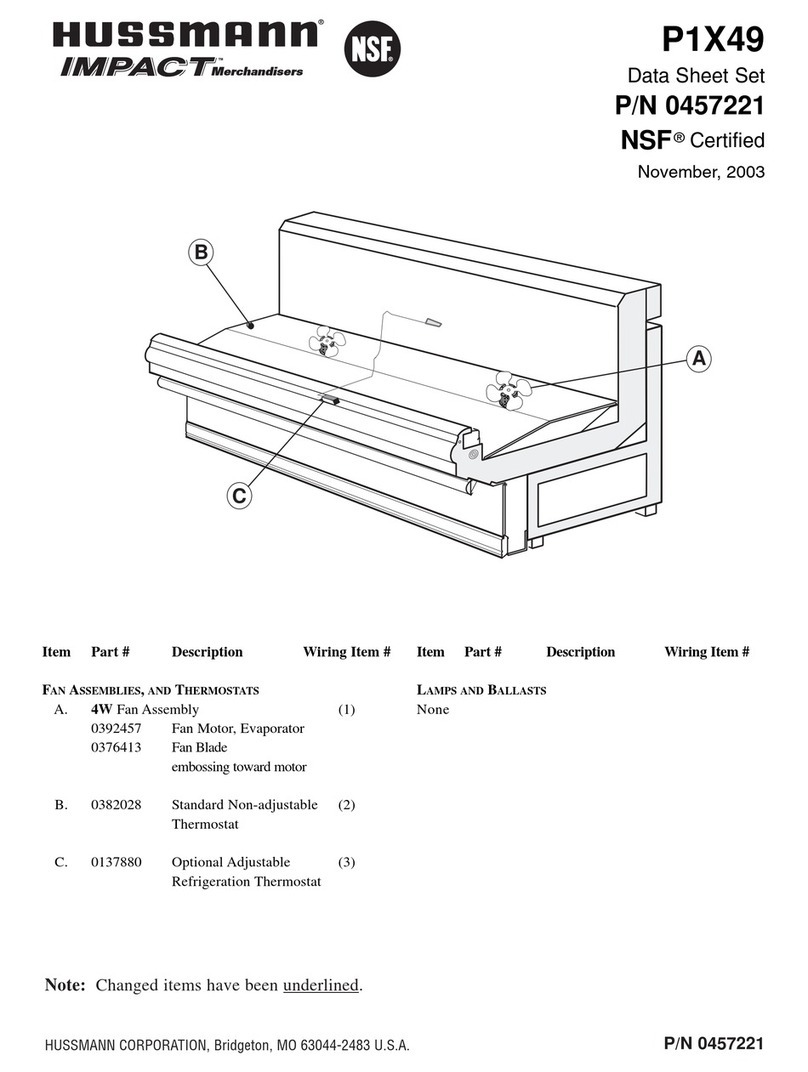

FAN SPEED CONTROL

Located in the electrical raceway on the lower right end

is a fan speed control.This control is set at the factory for

maximum.To adjust, turn the knob clockwise to obtain

approximately 50 FPM air speed.This may vary due to

store ambient conditions,especially the relative humidity.

With low humidity,slow the fan.With high humidity con-

ditions, set the control for maximum. Each case has its

own control and allows independant settings in case line-

ups.

NOTE: Slow air picks up more humidity from coil and ice.

Condenser Ventilation

Be sure to supply adequate ventilation for the condenser

in Self Contained units.Allow 150 square inches for units

up to 1 1/2 h.p.,and 200 for condensr units over 2 h.p.