CHAPTER 1- GENERAL INFORMATION......:.........................................:.....................1-1

General Description.................................. ....................................................................1-1

Unpacking and Uncrating..................................................................................................1-1

Specifications..........................................................................................................….......1-1

Equipment Supplied............................................................................................................1-1

Equipment Required But Not Supplied....................................................................…......1-2

CHAPTER 2

Safety Precautions...........……..........................…….................................................................2-1

General Safety Rules........................................................................................................2-1

Site Selection ....................................................................................................................2-2

CHAPTER 3

INSTALLATION PROCEDURES ............................................................................. 3-1

Checking Base Foundation Assembly...............................................................................3-1

Planning Your Procedure ..................................................................................................3-2

Foundation..........................................................................................................................3-2

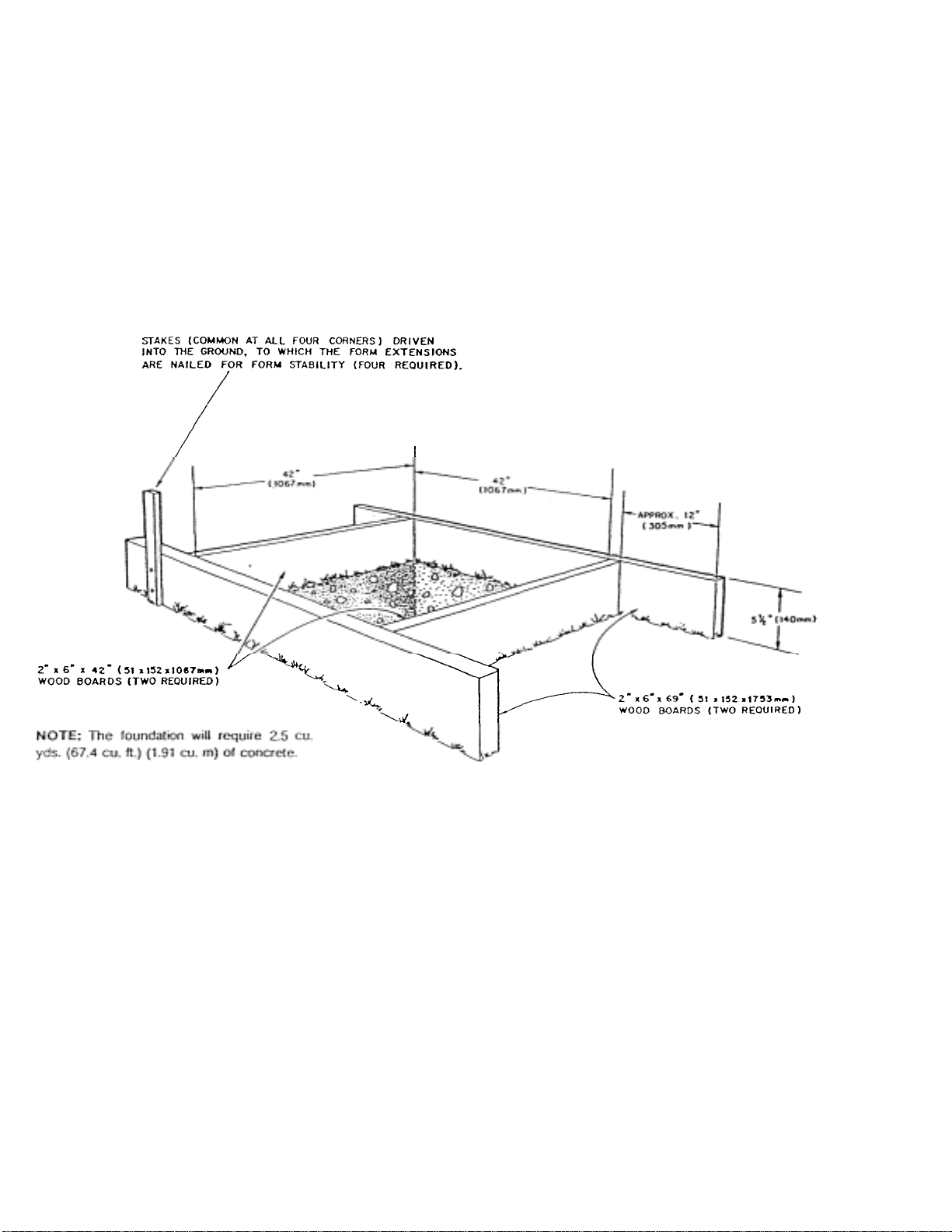

Wood Forms Construction...................................................'......................................... _..3-3

Attaching Tower to Base Plate...........................................................................................3-6

Lightning Protection...........................................................................................................3-9

Tower Maintenance.............................................................................................................3-9

Raising and Lowering Tower ..........................................................................................3-9

Procedures for Freein

Bindin

Tower Section...................................................................3-9

CHAPTER 4 - INSTALLATION INSTRUCTIONS

FOR ROTATOR AND MOUNTING PL.A.TE.........................................................................4-1

General ............................................................................................................................4-1

Rotator Installation..................................................................................................._......4-1

Parts List..........................................................................................................................4-4

LIST OF ILLUSTRATIONS

Fi

ure Pa

e

1 Overall View of HG-52-SS Tower.................. ............................................ i

2 Safe Location of Tower..................................................................,.......... 1-2

3 Checking Base Foundation Assembly........................................................3-1

4 Digging Hole for Foundation..................................................._.............._.3-2

5 Constructing Frame for Concrete Base.........................................................3-3

6 Top View of Foundation Structure Assembly ..............................................3-4

7Han

in

Base Foundation from Forms ...... ........................................ ....... 3-4

8 Attaching and Leveling Base Frame to Wood Forms ......................... ....... 3-5

9 Tower Foundation ..............................................................................................3-6

10 Attaching Tower to Base Tabs....................................................................... ...3-6

11 Su

ortin

Tower While Attachin

Related Products...................... ...... 3-7

12 Constructing Gin Pole...................................................................................._..3-7

13 Attaching Winch Assembly to Tower ......................................................... -....3-8

14 Connecting Cable to Winch .................._........................................................3-8

15 Freeing Binding Tower ._............_..................................................................3-10

16 Removable Brace............................................._.............._...............................4-1

17 Typical Installation of Rotator Mounted Below Plate .......................................4-2

18 Typical Installation of Rotator Mounted Above Plate ............................... . -4-2

19 Tower with Call-Outs of all Parts .......................... ...... .... ....... .............4-3