2

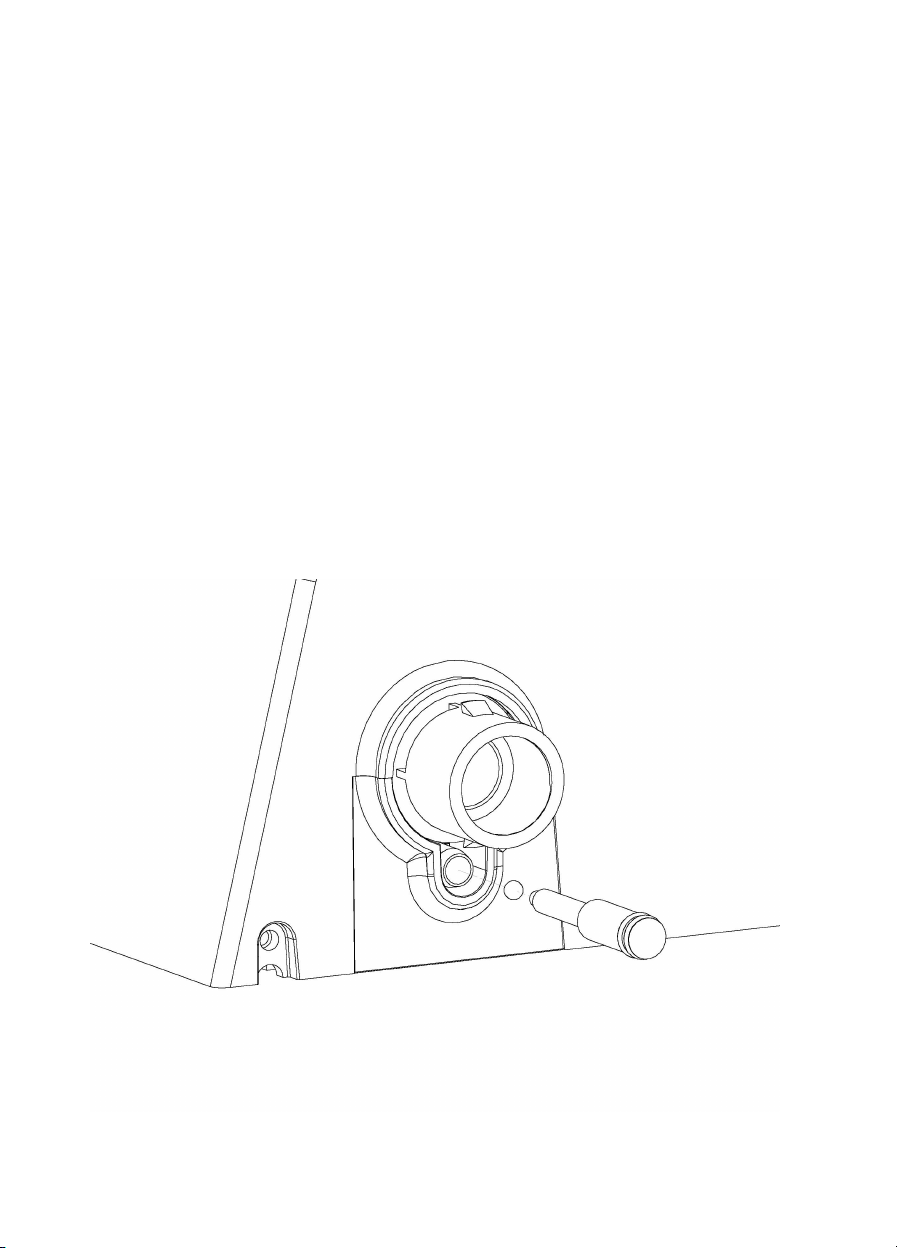

Thank you for purchasing a Hyco Wave hand wash unit. The Wave offers

an indefinite supply of hot water thanks to its instantaneous operation.

Without the standing losses associated with storage type heaters, the unit

is a very energy efficient solution for light hand washing at a single basin.

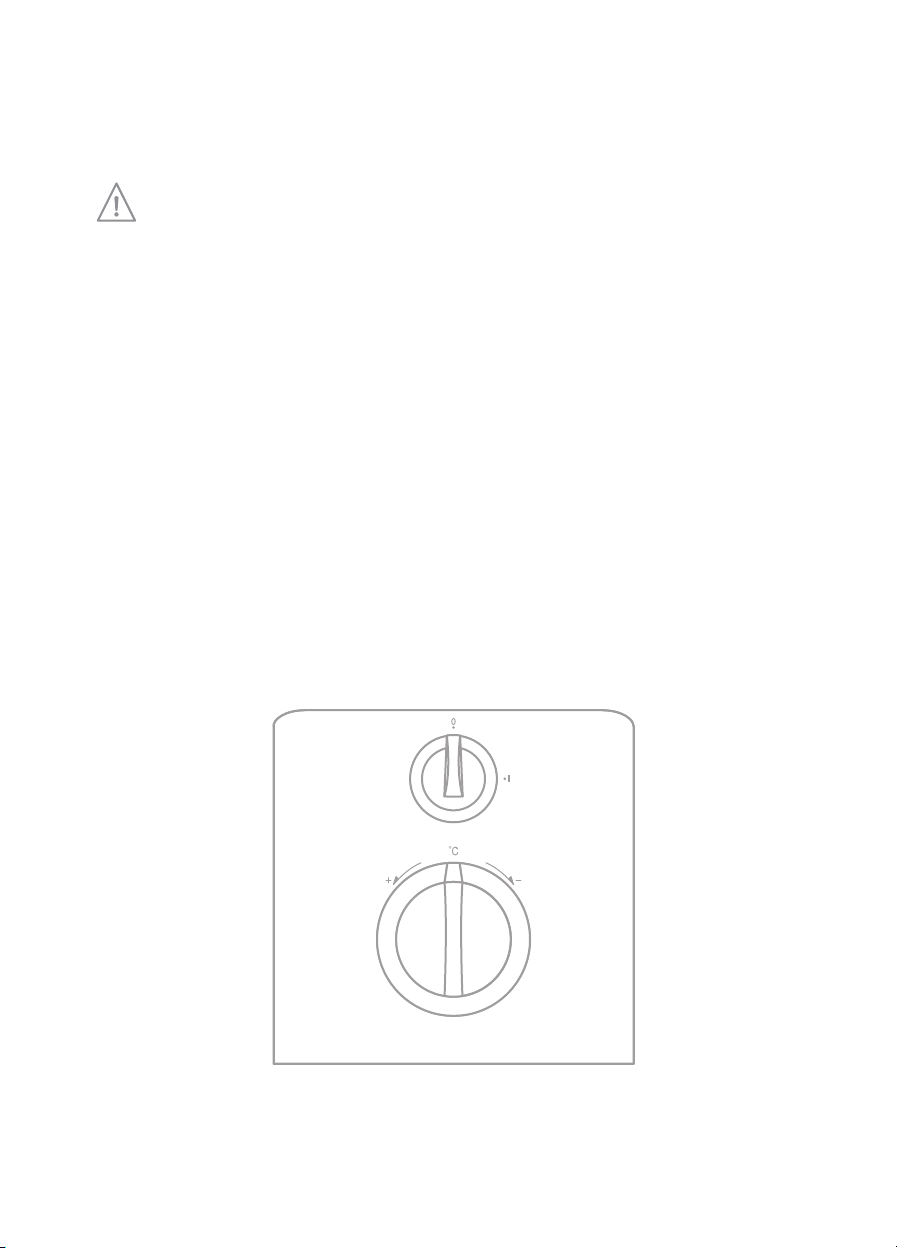

The Wave is available in two models; the HW30A operates automatically

via an infra-red sensor and the HW30M is operated manually via a rotating

knob on the front of the unit. Please read and understand these instructions

before commencing installation and leave them with the user when

installation is complete.

1. Impor an safe y poin s

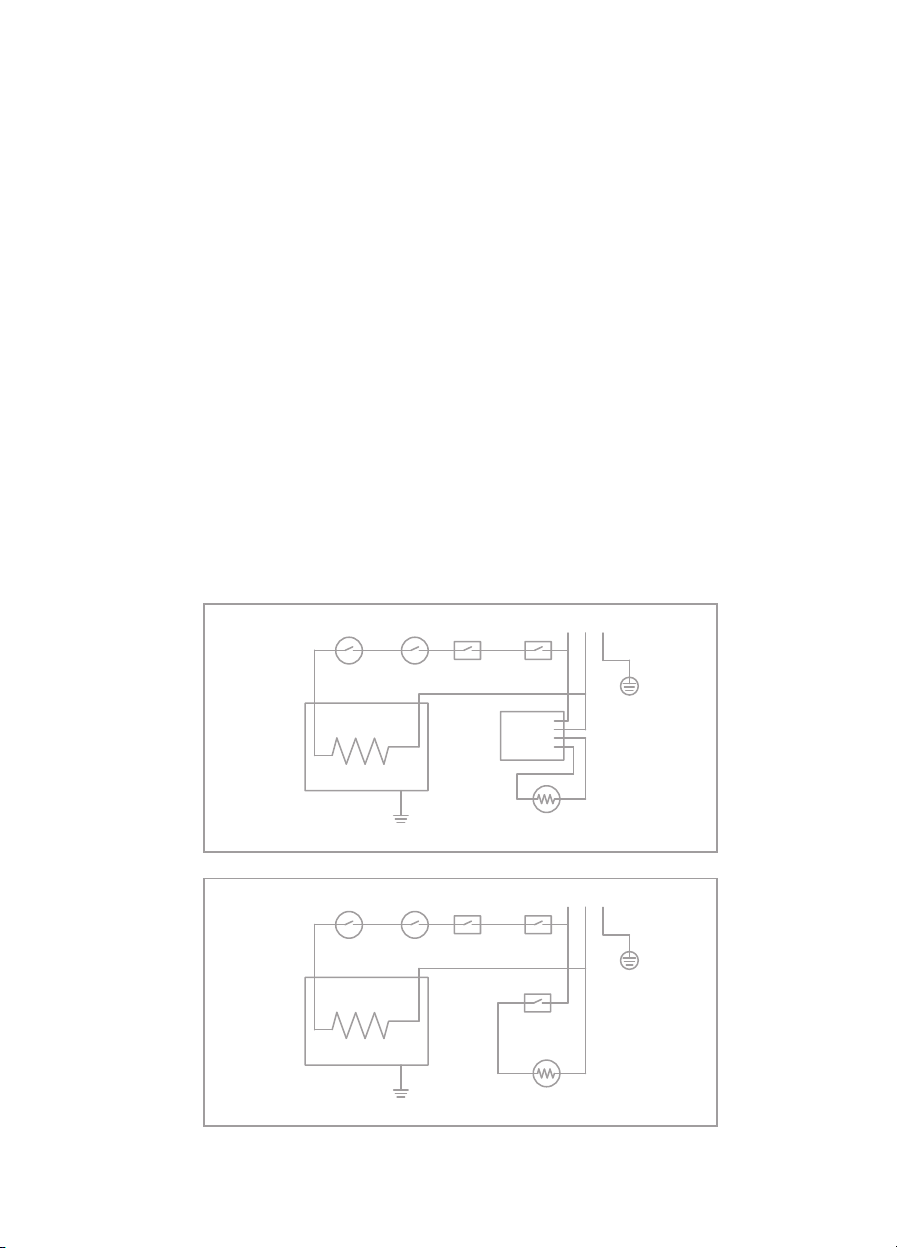

•Electrical installation must be carried out by a qualified electrician in accordance

with the latest edition of the IET wiring regulations.

•This appliance must be earthed.

•Means for electrical disconnection must be incorporated into the fixed wiring in

accordance with the wiring rules.

•This appliance is intended as an open outlet heater. Only use the spout supplied

with the unit and do not attempt to modify the spout or the spray head in any

way.

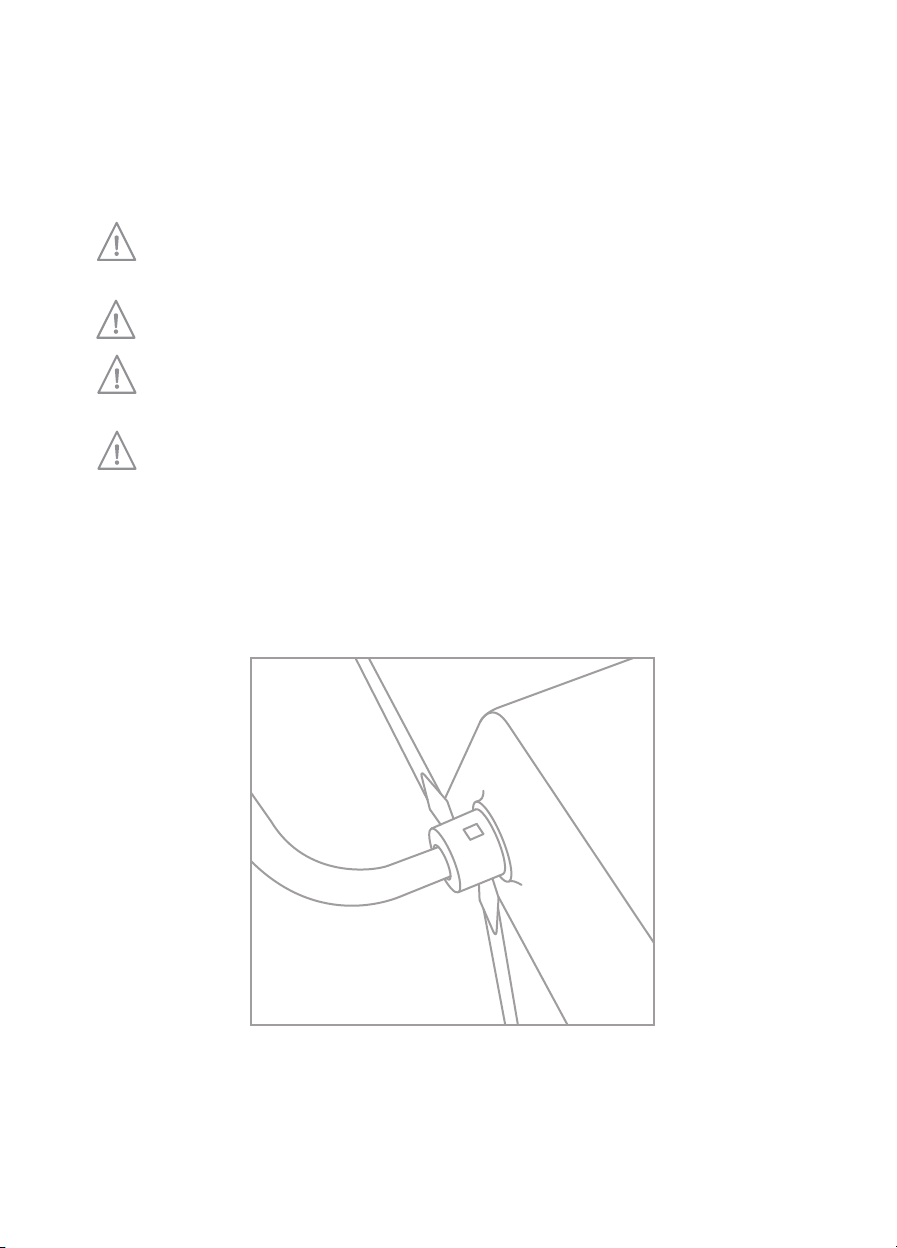

•The spray head must be descaled regularly to ensure it remains unimpeded and

free from debris and to avoid a pressure build up.

•This appliance incorporated a safety relief valve ; do not attempt to modify this

in anyway.

•Do not switch on if there is a possibility that the water in the heater is frozen.

•Do not use the appliance in an ambient temperature exceeding 30°C.

•This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of

the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.