Safety

Hycomp ensures that safety is designed into every

compressor. An Odyssey booster is a precision, high

speed, mechanical piece of equipment. It requires

caution in operation to minimize hazard to self and

property.

All Odyssey boosters have various caution, warning,

and danger labels which must be heeded and should

not be removed. Before operating or performing any

maintenance, read the Odyssey Operation Manual.

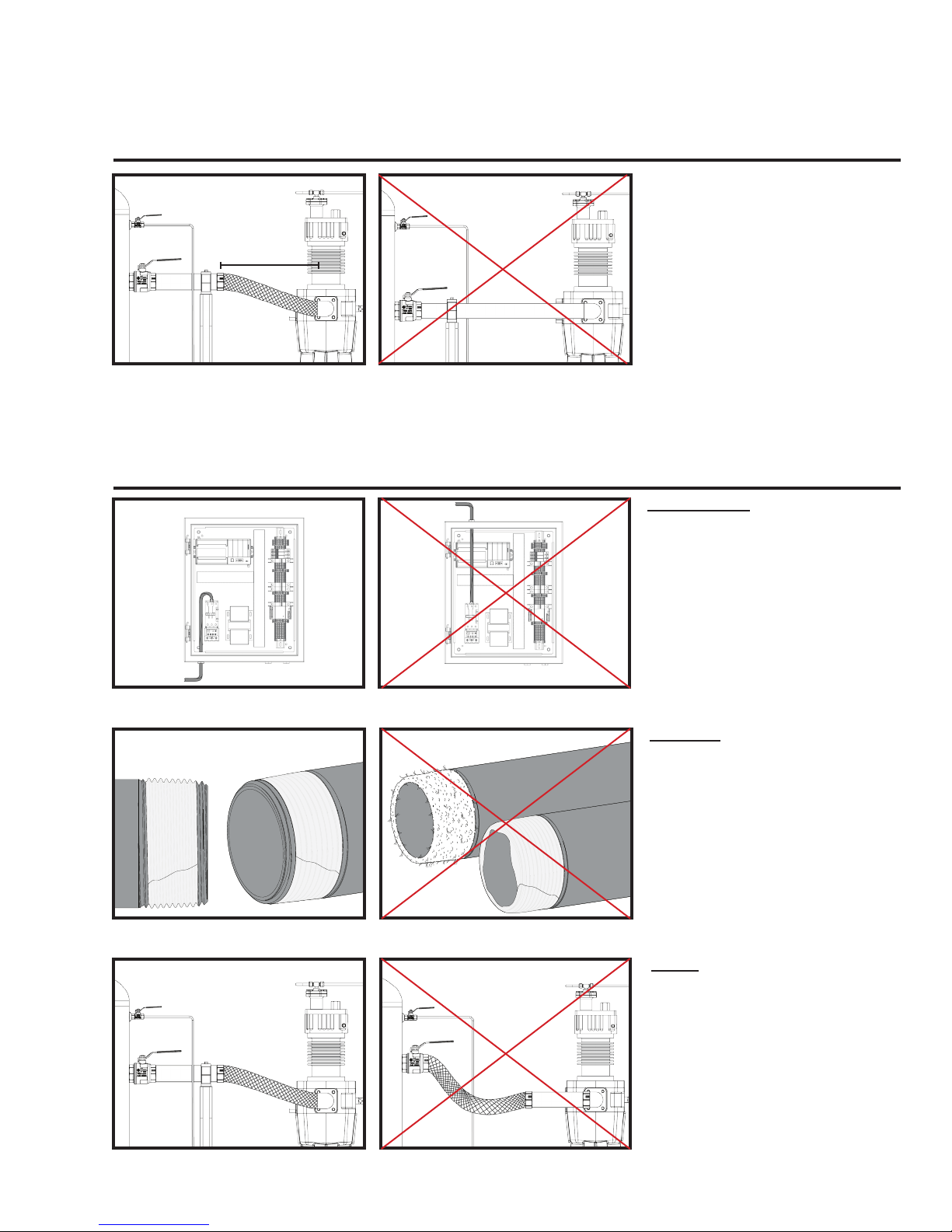

qReciprocating boosters must be mounted

on a reinforced concrete foundation (6 bag /

4000psi mix) and mounted with epoxy grout, per

“Foundation” section of this manual.

qCompressors and packages mounted to onshore

transportable platforms or any elevated structure

must be securely fastened to adequately

constructed subframes.

qAllow for 18” of clearance for air circulation and

service access around the booster. 36” in front of

the Control Panel. See “Location” section.

qOutdoor compressor installations must be

protected from the eects of the environment;

e.g. cold, heat, rain, sun, dust, etc. Machinery

exposed to the elements requires increased

maintenance and experiences decreased service

life. A block heater with thermostat is required for

cold climates.

qA power disconnect for the machine must

be installed as per NEC & local power utility

code. Follow Lockout/Tagout procedures, per

OSHA Regulation 1910.147, before any work is

performed. Do NOT work on equipment while it

is running.

qLockout/tagout the compressor control panel and

tighten all electrical connections within the control

panel before startup. Connections can come

loose during shipping leading to intermittent

faults.

q Use threaded or anged exible braided metal

hose connections of proper pressure rating to

connect the booster system suction and discharge

ports. Do not use rubber hose.

qNitrogen Boosters must have an suction receiver

sized per “Receivers” section of this manual.

Ensure that suction and discharge receiver tanks

are secured and bolted down.

qPlace properly sized pressure safety valves

protecting the suction and discharge piping

systems, between the compressor and any

isolation ball valve, per ASME Code.

qInstall supplied check valve into dedicated port of

discharge receiver tank.

qProtect personnel from high temperature piping/

tubing by insulating, warning, and or restricting

access to the machine boundary.

qPressure sensing lines to pressure transmitters

must be 3/8” tubing or larger, and drawn from

the corresponding receiver, not from the suction/

discharge piping.

qRoute clear tubing, located on motor side of

booster, to an oil catchment location. Small

amounts of oil will accumulate over time.

qUse double nut, Nyloc nut, or Loctite on foundation

bolting. Check all bolting after the rst few hours

and days of operation for tightness.

q Re-torque all head and ange bolts after the rst

40 hours of operation, per the Odyssey Operation

Manual.

qRe-tighten pressure connections, including tube

ttings, pipe connections, and ange connections,

after initial operation.

qOdyssey Boosters must have a properly sized

lter installed at the suction receiver inlet to

protect the booster from damage caused by

system contamination. Filter should be 1 micron

or better and sized for minimal pressure drop.

qBoosters are shipped with ISO/SAE 30 wt

synthetic oil. Refer to Odyssey Operation

Manual to ensure this is appropriate for your

environmental conditions.

q Check your system for leaks, x as required.

Remove all pressure from system, isolate

and drain, before attempting xes, per OSHA

Regulation 1910.147

qEnsure all components and piping installed with

Odyssey booster are compatible with Nitrogen.

qComplete the Hycomp Warranty Registration

Card and Warranty Checklist.

INSTALLATION CHECKLIST - REVIEW BEFORE CONTINUING