i S23 2001a

S23 Table of Contents

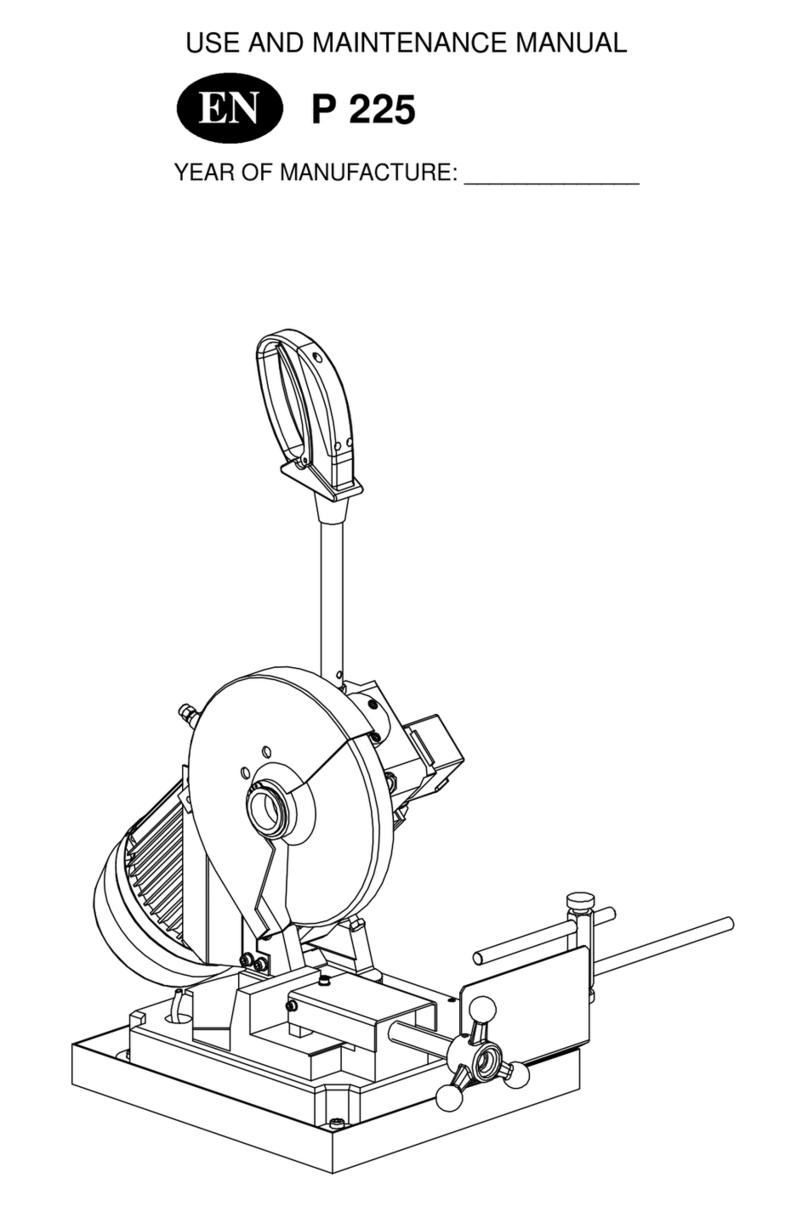

SECTION 1, INSTALLATION

SAFETY PRECAUTIONS ........................................................................................................................................ 1

LIFTING THE S-23 with a FORK LIFT ..................................................................................................................... 2

WRAPPED FOR SHIPPING .................................................................................................................................... 2

LEVELLING THE SAW............................................................................................................................................. 3

HYDRAULIC OIL ...................................................................................................................................................... 3

CUTTING FLUID ...................................................................................................................................................... 3

SPEED ADJUSTOR INSTALLATION ........................................................................................................................ 3

POWER CABLE ROUTING...................................................................................................................................... 4

POWER WIRING CONNECTIONS ........................................................................................................................... 4

SECTION 2, OPERATION INSTRUCTIONS

OPERATOR CONTROL PANEL ................................................................................................................................ 5

HYDRAULIC CONTROLS ................................................................................................................................... 5

ELECTRICAL CONTROLS.................................................................................................................................. 5

BLADE BASICS ..................................................................................................................................................... 6

DETERMINE OPTIMUM BLADE PITCH .................................................................................................................. 7

VISE OPERATION ................................................................................................................................................... 7

BLADE SPEED ADJUSTMENT ............................................................................................................................... 8

HEAD SWING and BREAK ..................................................................................................................................... 8

GUIDE ARM POSITIONING .................................................................................................................................... 9

COOLANT FLOW..................................................................................................................................................... 9

SECTION 3, MAINTENANCE and TROUBLESHOOTING

BLADE CHANGING PROCEDURE ........................................................................................................................ 11

BLADE TRACKING ADJUSTMENT .................................................................................................................. 12

Idler Wheel Adjustment ................................................................................................................................ 12

Drive Wheel Adjustment ............................................................................................................................... 12

BLADE GUIDE ADJUSTMENT ......................................................................................................................... 13

BLADE BRUSH ADJUSTMENT ........................................................................................................................ 13

ANGLE BRAKE ADJUSTMENT and PROCEDURE ............................................................................................... 13

DRIVE BELT REPLACEMENT .............................................................................................................................. 14

HEAD DOWN LIMIT SWITCH ................................................................................................................................ 14

LUBRICATION ....................................................................................................................................................... 15

TROUBLE SHOOTING GUIDE .............................................................................................................................. 16

SERVICE RECORD & NOTES ............................................................................................................................... 17

SECTION 4, ELECTRICAL SYSTEM

CONTROL PANEL & COMPONENTS .................................................................................................................... 19

ELECTRICAL COMPONENTS LISTS .................................................................................................................... 20

ELECTRICAL DRAWINGS ..................................................................................................................................... 22

ELECTRICAL DRAWINGS c/w blade breakage option ........................................................................................... 24

---- Continued ----