PG 2.2

BLBL

BLBL

BLADE BADE B

ADE BADE B

ADE BASICSASICS

ASICSASICS

ASICS

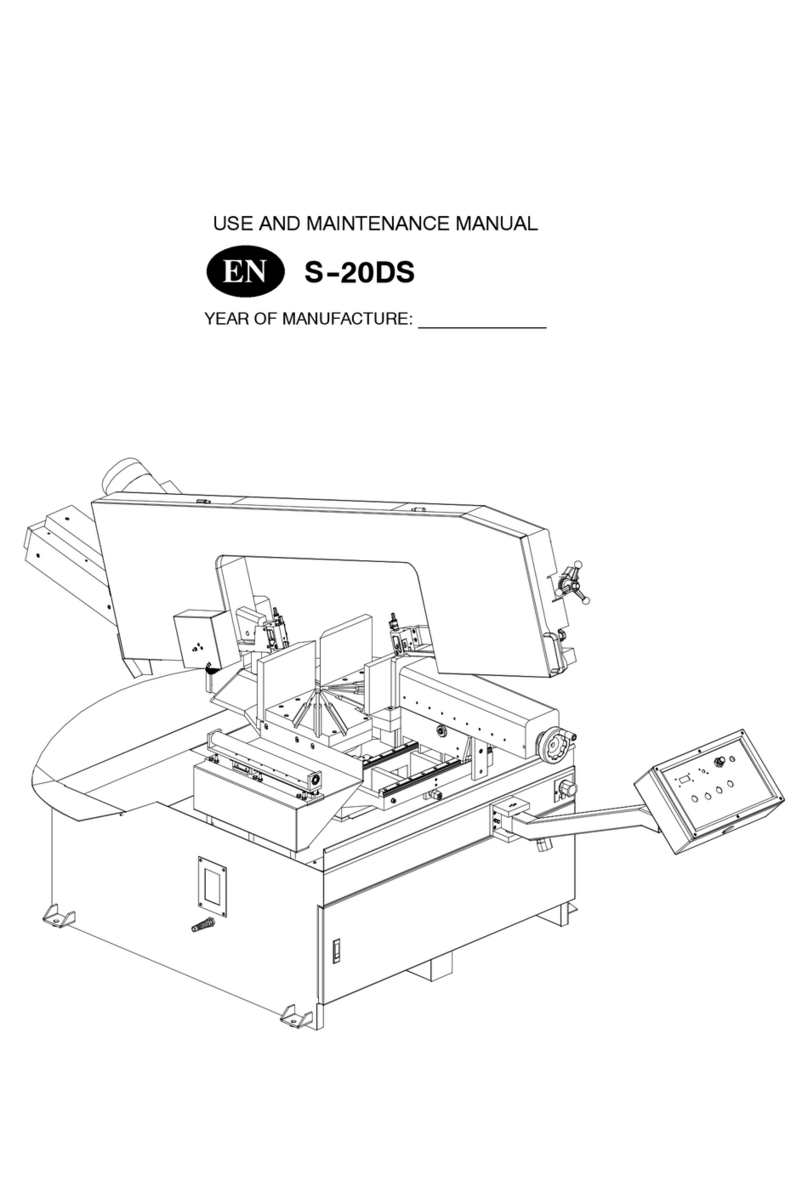

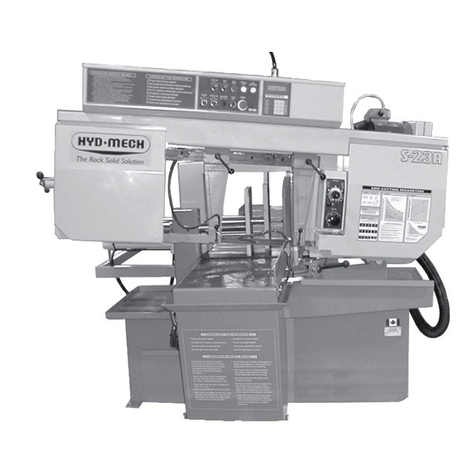

Technology is rapidly changing all aspects of production machining. Metal cutoff is no exception.

The advances made in the bandsaw blade industry have definitely brought down the cost per cut, despite

the three fold higher price of the newer technology blades. Variable pitch (see Pg 2.3), bi-metal blades

(like the 5/8 or 4/6 bi-metal blade supplied with the S-20 Series II saws) last much longer, cut faster, and

more accurately than the conventional carbon steel blades. In order to take advantage of the superiority

of bi-metal blades, it is critical to property break-in a new blade. This is accomplished by taking two or

three cuts through solid four or five inch diameter mild steel at an extremely slow feed rate. These two or

three slow cuts sufficiently lap (polish) the new blade so that it does not snag the material being cut.

Proper break-in will alleviate blade vibration, improve surface finish and accuracy, and improve expected

blade life.

1. A neA ne

A neA ne

A new bw b

w bw b

w blade mlade m

lade mlade m

lade must be prust be pr

ust be prust be pr

ust be properoper

operoper

operly "brly "br

ly "brly "br

ly "brokok

okok

oken-in"en-in"

en-in"en-in"

en-in"..

..

. Proper break-in will alleviate blade vibration, improve

surface finish and accuracy, and extend blade life. The most convenient way to do this is to cut the

intended work-piece, at the standard recommended blade speed for that material, but with the feed

rate reduced to about 25% of normal. Near the end of the first cut, increase the feed rate again, and

once again when the blade approaches the end of the second cut. Keep increasing feed rate in this

fashion, so that normal feed rate is reached after 300 to 500 sq. cm of cutting.

2. GenerGener

GenerGener

Generous coolant aous coolant a

ous coolant aous coolant a

ous coolant applicapplica

pplicapplica

pplication is essential with almost all mation is essential with almost all ma

tion is essential with almost all mation is essential with almost all ma

tion is essential with almost all materialsterials

terialsterials

terials. A high quality and well mixed

coolant will dramatically extend blade life, and will increase cutting rate and surface finish. On those

few materials where coolant is undesirable, a slight coolant flow or periodic oiling of the blade is

necessary to prevent the blade from being scored by the carbide guides.

3. TT

TT

The stoche stoc

he stoche stoc

he stock being cut mk being cut m

k being cut mk being cut m

k being cut must be securust be secur

ust be securust be secur

ust be securely cely c

ely cely c

ely clamped in the viseslamped in the vises

lamped in the viseslamped in the vises

lamped in the vises..

..

. Stock movement during cutting will strip

blade teeth. Noticeable stock vibration reduces cutting performance and blade life - consideration

should be given to reorientation of the stock, or additional clamping measures (e.g. wood between

vise jaws and work-piece).

4. TT

TT

The prhe pr

he prhe pr

he proper boper b

oper boper b

oper blade speed flade speed f

lade speed flade speed f

lade speed for the wor the w

or the wor the w

or the woror

oror

ork-piece mak-piece ma

k-piece mak-piece ma

k-piece material mterial m

terial mterial m

terial must be selectedust be selected

ust be selectedust be selected

ust be selected..

..

.

Use the following chart as a starting point.

- Blade speeds higher than recommended will quickly dull the blade. Blue chips are evidence of

excessive blade speed.

- Lower than recommended speeds will not prolong blade life, and will require reduced feed rate - but

reduced speeds may be helpful in reducing vibration, and will increase blade life in that case.

5. TT

TT

The prhe pr

he prhe pr

he proper foper f

oper foper f

oper feed reed r

eed reed r

eed raa

aa

ate mte m

te mte m

te must be aust be a

ust be aust be a

ust be appliedpplied

ppliedpplied

pplied..

..

. Feed Rate is the speed which the head "free-falls", and is set

with the feed rate control knob. The head will descend more slowly when the blade encounters the

work-piece but the force of the blade on the work will not be changed unless the setting is changed.

Verification of proper feed rate is provided by the appearance of the cut chips which ideally form

nicely curled "clock springs". (Note that cast irons, and interrupted cuts result in short, broken chips

even at ideal feed rates).

- Excessive feed rate will result in short blade life and/or crooked cuts.