Hydra-Power Hydraulic Power Pack Operation Instructions HSPWRPK v1.11 Revised March 2016

Specifications subject to change without notice.

SECTION 3 - SAFETY WARNINGS

Conventions used in this manual include:

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in serious injury

or death.

NOTE signifies an important point of

information.

Read this manual thoroughly before operating your

Hydra-Power PowerPack. Failure to follow instructions

could result in serious injury or death.

Engine exhaust contains carbon monoxide, a colorless,

odorless, poison gas. Breathing carbon monoxide will

cause nausea, dizziness, fainting or death. If you start to

feel dizzy or weak, get to fresh air immediately.

Operate Hydra-Power PowerPack outdoors only in a well

ventilated area.

DO NOT operate the Hydra-Power PowerPack inside any

building, including garages, basements, crawlspaces and

sheds, enclosure or compartment.

DO NOT allow exhaust fumes to enter a confined area

through windows, doors, vents or other openings.

Rotating parts can entangle hands, feet, hair, clothing and/

or accessories.

Traumatic amputation or severe laceration can result.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

Operate equipment with guards in place.

DO NOT wear loose-fitting clothing, dangling drawstrings or

items that could become caught.

Sparks can result in fire or electrical shock. When servicing

the Hydra-Power PowerPack:

Disconnect the spark plug wire and place it where it cannot

contact the plug. DO NOT check for spark with the plug

removed. Use only approved spark plug testers.

Running engines produce heat. Severe burns can occur

on contact. Combustible material can catch fire on contact.

DO NOT touch hot surfaces.Avoid contact with hot exhaust

gases. Allow equipment to cool before touching. Maintain at

least three feet of clearance on all sides to ensure ade-

quate cooling. Maintain at least five feet of clearance from

combustible materials.

Fuel and fuel vapors are highly flammable and extremely

explosive. Fire or explosion can cause severe burns or

death. Unintentional startup can result in entanglement,

traumatic amputation or laceration.

When adding or removing fuel: Turn the Hydra-Power

PowerPack off and let it cool for at least two minutes before

removing the fuel cap. Loosen the cap slowly to relieve

pressure in the tank. Only fill or drain fuel outdoors in a

well-ventilated area. DO NOT pump gas directly into the

Hydra-Power PowerPack at the gas station. Use an ap-

proved container to transfer the fuel to the Hydra-Power

PowerPack. DO NOT overfill the fuel tank.Always keep fuel

away from sparks, open flames, pilot lights, heat and other

sources of ignition.

DO NOT light or smoke cigarettes while fueling the Hy-

dra-Power PowerPack.

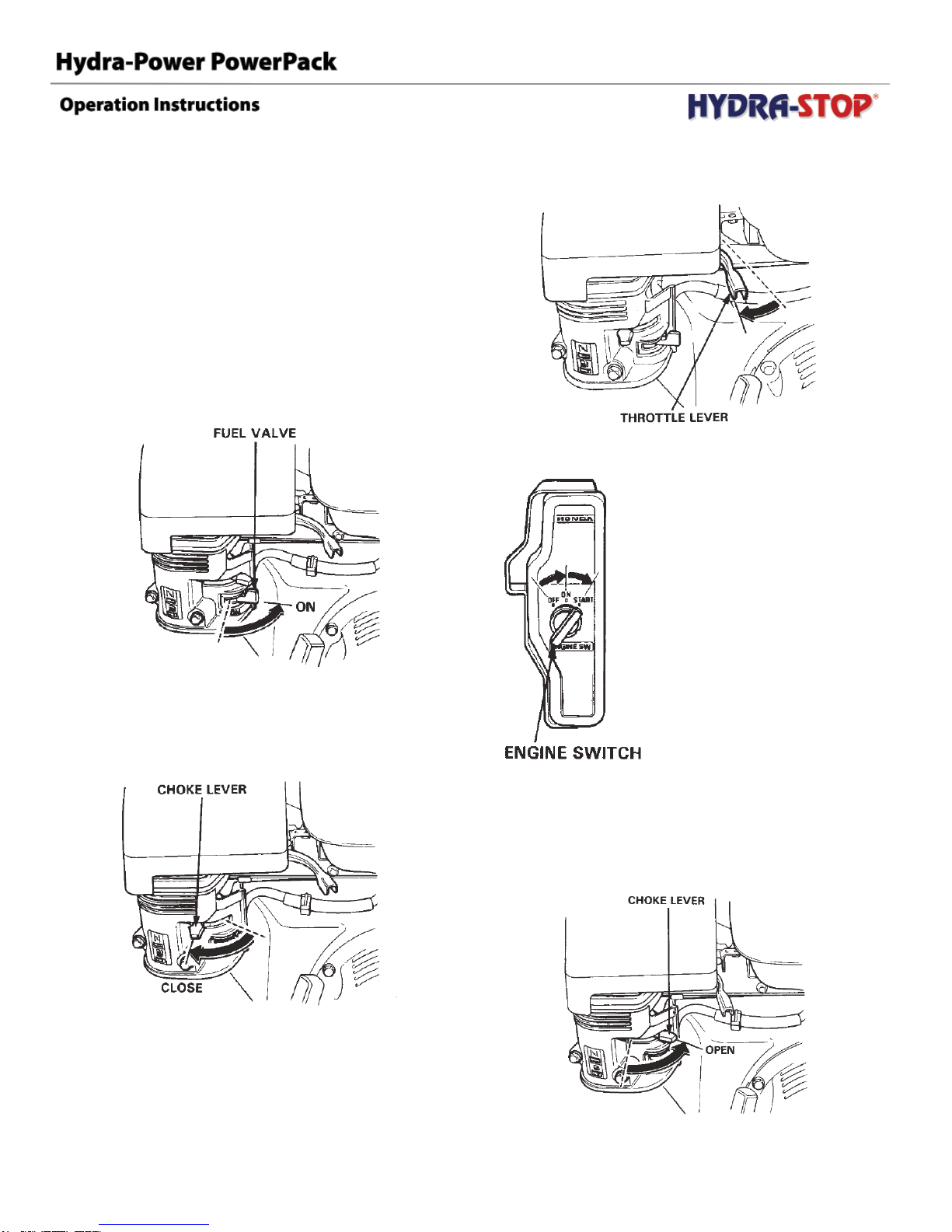

When starting the Hydra-Power PowerPack engine:

DO NOT attempt to start a damaged engine.

Make certain that the gas cap, air filter, spark plug, fuel

lines and exhaust system are properly in place.

Allow spilled fuel to evaporate fully before attempting to

start the engine.

Make certain that the Hydra-Power PowerPack is resting

firmly on level ground.

When operating the Hydra-Power PowerPack:

DO NOT move or tip the Hydra-Power PowerPack or allow

fuel or oil to spill.

When transporting or servicing the Hydra-Power Pow-

erPack:

Make certain that the fuel shutoff valve is in the off position

and the fuel tank is empty.

Disconnect the spark plug wire.

When storing the Hydra-Power PowerPack:

Store away from sparks, open flames, pilot lights,heat and

other sources of ignition.