2 ZT-2800®/ZT-3100®/ZT-3200TM

-

-

WARNING

Actuating the bypass will result in the

loss of hydrostatic braking capacity. The

machine must be stationary on a level

surface and in neutral when actuating

the bypass.

Introduction

-

®

ZT-2800®®

-

-

Do not use a pressure washer to

clean the unit.

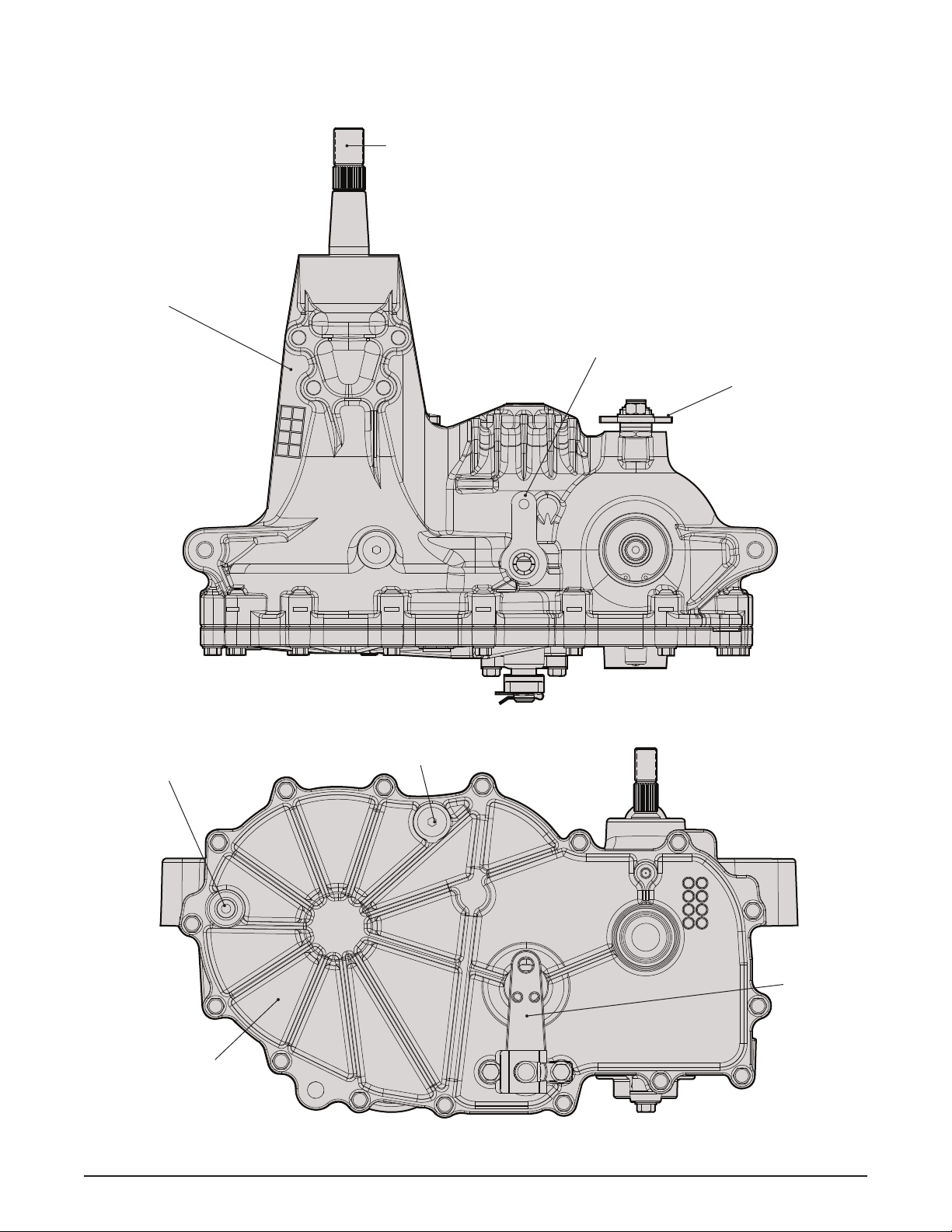

General Description

-

-

-

DESCRIPTION AND OPERATION