Installation Manual 5.1.2

6

1.0 Transportation & Storage

Move and store units in an

upright position. Do not stack

units. Inspect shipment for

shipping damage and check

packing slip for accuracy. Any

equipment or cartons in question should be removed

from the packing and physically inspected. If any

damage is detected, the carrier should make a note on

the delivery slip acknowledging the damage. In some

cases smaller items like thermostat or temperature

sensors will be packed and shipped inside the system.

During freezing conditions special consideration should

be made to prevent unit damage. If a unit is taken to

the job site or put in storage, anti-freeze will need to

be pumped into the water coils to prevent freezing.

Failure to do this will void warranty.

2.0 Electrical Hazard Warnings

THE FOLLOWING IS A GENERAL WARNING

STATEMENT WHICH SHOULD BE READ AND

UNDERSTOOD BEFORE INSTALLING AND OR

OPERATING YOUR NEW HYDRO-TEMP UNIT

ELECTRIC SHOCK CAN KILL!!

•Always protect yourself and others. Always turn off

system power before removing panels. Some units

may have more than one or two power supplies.

•Keep all covers and panels in place at all times. When

removed for install or service purposes never leave

the cover off when left un-attended.

•Do not stick hands into return or any other opening.

•All repairs, electrical or mechanical, should be

attempted only by trained Hydro-Temp technicians.

In the event of a unit problem, do not reset the

equipment before correcting the problem.

Equipment failure due to resetting without first

correcting the problem will not be covered by the

warranty.

•The presence of water around the base of the unit

constitutes an electrical hazard. Turn off the power

to the unit as soon as water leakage is discovered and

call a service technician immediately.

•STRIP HEAT WARNING: On systems with

auxiliary/emergency heat strips, be aware that the

heat strip contactor may be wired on a separate

circuit. Therefore an additional breaker must be shut

off before removing panels and servicing unit.

•All breakers/fuses supplying power to this equipment

should be clearly labeled at time of installation.

•All wiring and plumbing should be done in strict

accordance with local and national codes and

ordinances.

2.1 Electrical Connections

Power to the Hydro-Temp System and back-up

electric heater may be two or sometimes three

circuits (Some large dual compressor systems will

require a circuit per compressor). A standard system

requiring one circuit for compressor and one circuit

for strip heat can be wired with 2 breakers in the

main breaker panel or one circuit feeding a sub

breaker panel near the system. All circuits must have

its own power disconnect near the system. The

electrical installation must be performed by a licensed

electrician, except for the low voltage wiring (Class 2)

(i.e. T-Stat) which can be done by the heat pump

contractor. Note: In most areas high voltage can be

taken from disconnect to the unit by the mechanical

contractor if allowed by local codes. All wiring and

plumbing should be done in strict accordance with

local and national codes and ordinances.

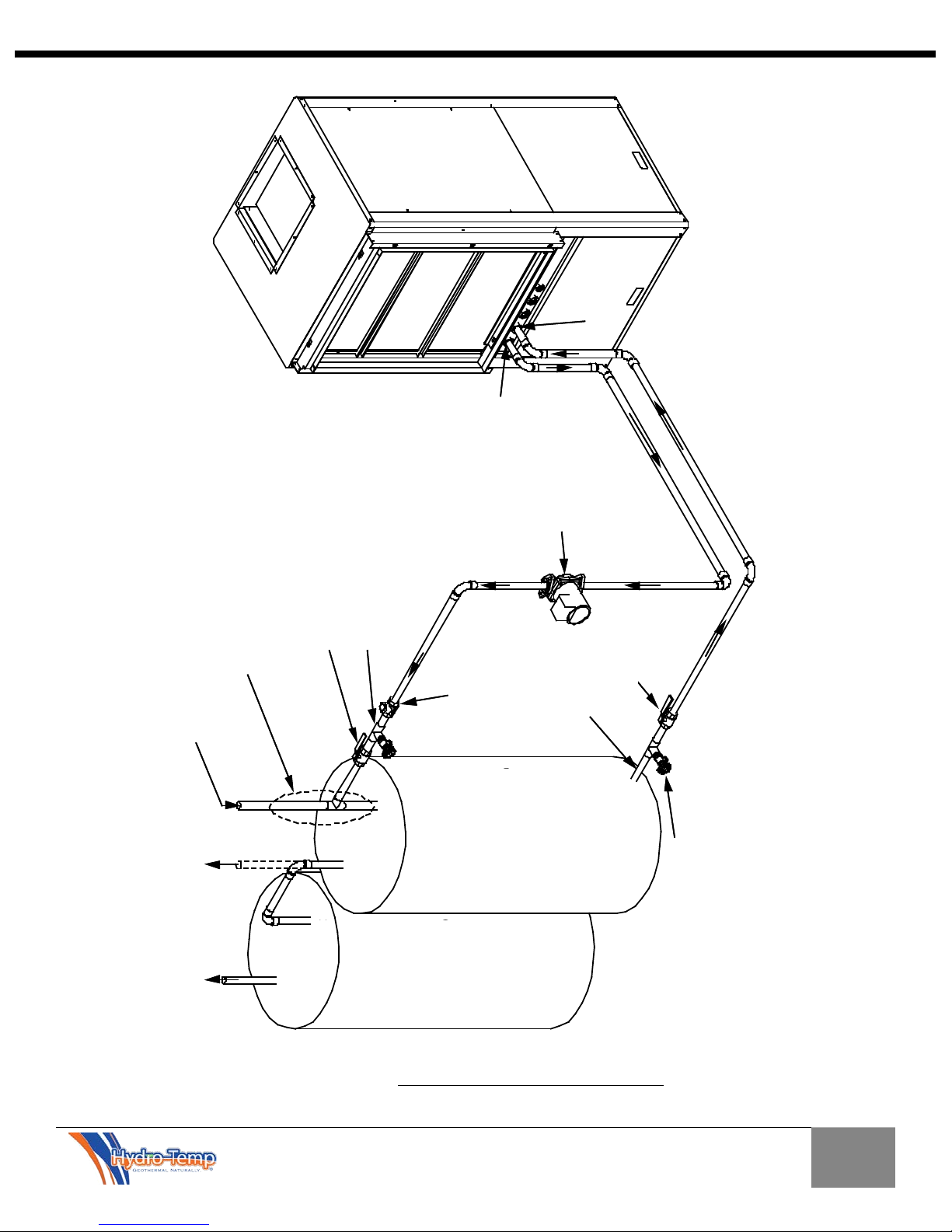

3.0 Hydro-Temp System Installation

Locate the unit in a conditioned, indoor area that allows

for easy servicing. Make sure that the air filter access

and unit access panels are easily accessible. Provide

sufficient room to make all ground loop, well water,

DHW, condensate, electrical, and if applicable

refrigeration connections.

If the unit is placed in a closet, make provision for

adequate return air flow to the unit.

Some installations may require a condensate pump to

take the condensate to a suitable drain location. Do not

locate the unit in an area that is subject to

freezing. The minimum recommended room

temperature for equipment location is 60°F. Provide a

heated, insulated enclosure for the unit where

necessary.