3.3 IMPORTANT INSTALLATION POINTS

3.3.1 This unvented water heater MUST be tted with the Pressure Relief

Valve supplied. FAILURE TO PROVIDE ADEQUATE PRESSURE

RELIEF WILL INVALIDATE ANY GUARANTEE AND LEAD TO A

DANGEROUS INSTALLATION.

3.3.2 Expansion can take place within the cold water supply PROVIDED

THAT BOTH :

(a) Backow in the main is not prevented by any stop valve with loose

jumper, check valve, pressure reducing valve or similar AND

(b) Hot water expansion does not enter a branch to a cold water outlet

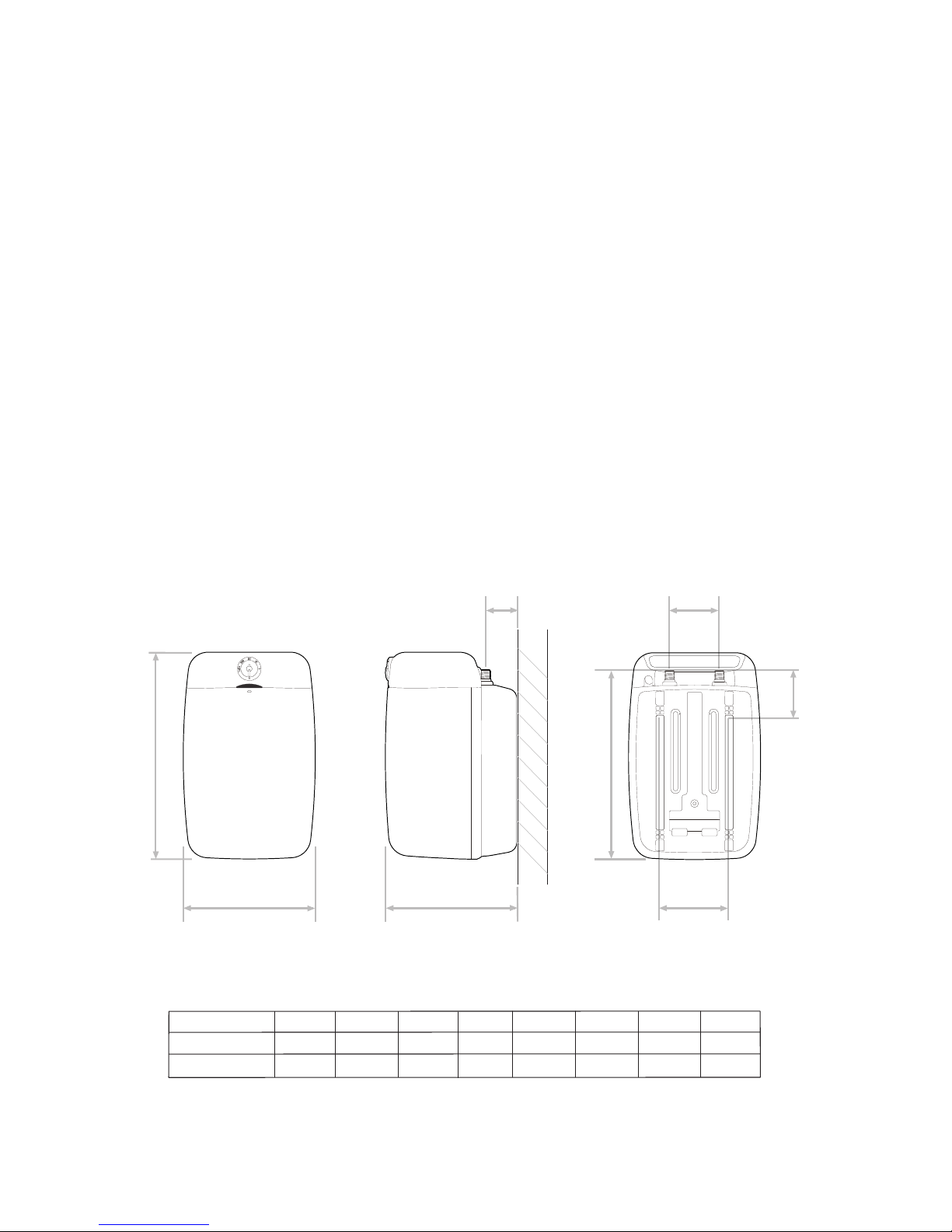

(see Figure 02, page 6 for expansion pipe lengths).

N.b. Both the above conditions must be met. Additionally expansion

within the cold water supply will not be possible if the static supply

pressure exceeds 0.41 MPa (4.1bar).

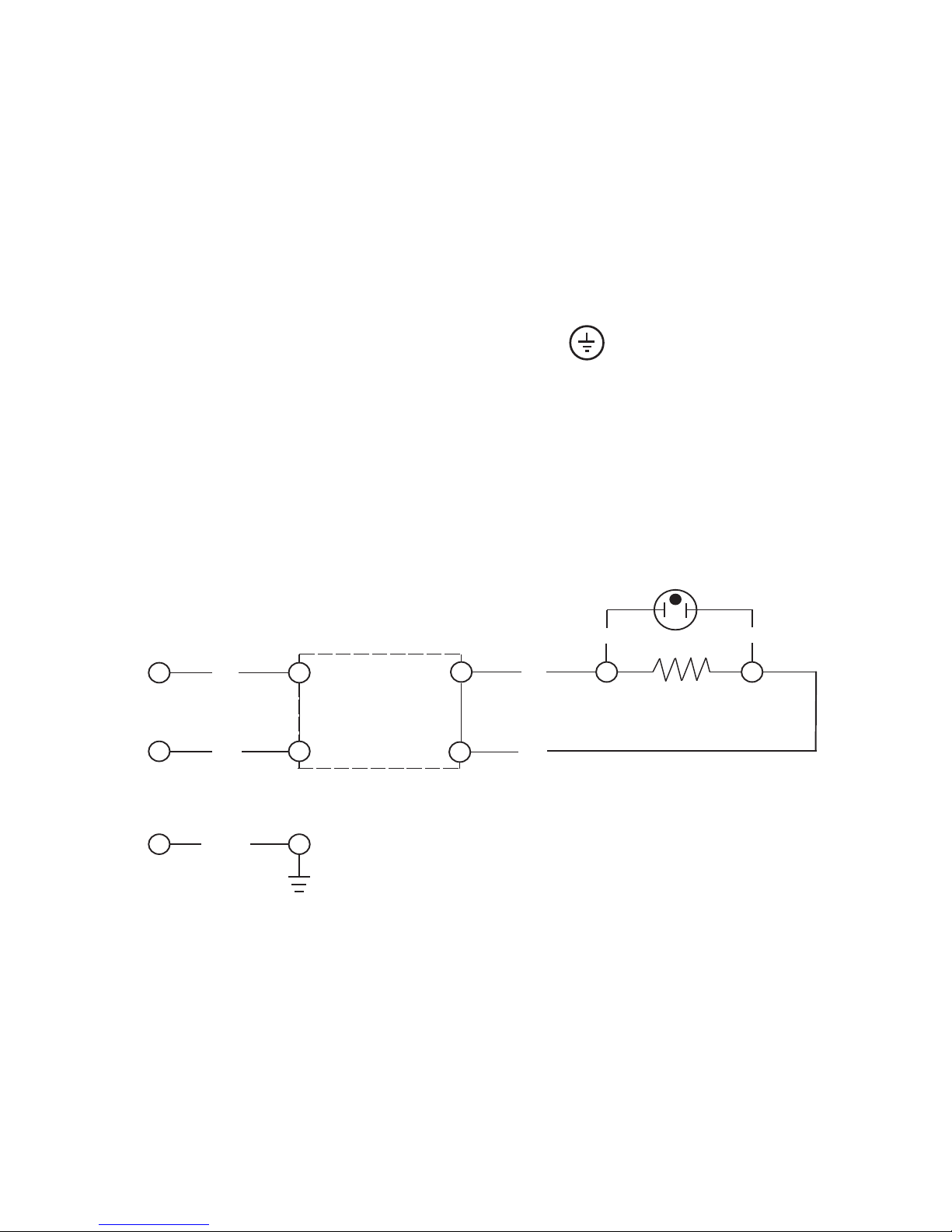

3.3.3 If any of the conditions in 3.3.2 cannot be met, expansion must be

accommodated using an Expansion Vessel. To ensure all expansion

takes place in the vessel, a check valve must also be tted together

with the Pressure Relief Valve supplied (see Figure 03, page 6).

3.3.4 If the static supply pressure exceeds 0.41 MPa (4.1 bar), a Pressure

Reducing Valve must be tted to the cold main supply. If a Pressure

Reducing Valve is used, an Expansion Vessel must also be used (see

Figure 04, page 6).

3.3.5 The installation must be carried out in accordance with the relevant

requirements of:

• The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland) or Building

Regulations (Northern Ireland).

• The Water Fittings Regulations or Water Byelaws in Scotland.

WARNING: IF WATER FLOWS FROM THE PRESSURE RELIEF VALVE,

THE ELECTRICITY SUPPLY MUST BE SWITCHED OFF IMMEDIATELY.

CONTACT A COMPETENT INSTALLER FOR UNVENTED WATER HEATERS

TO CHECK THE SYSTEM.