4

Product description

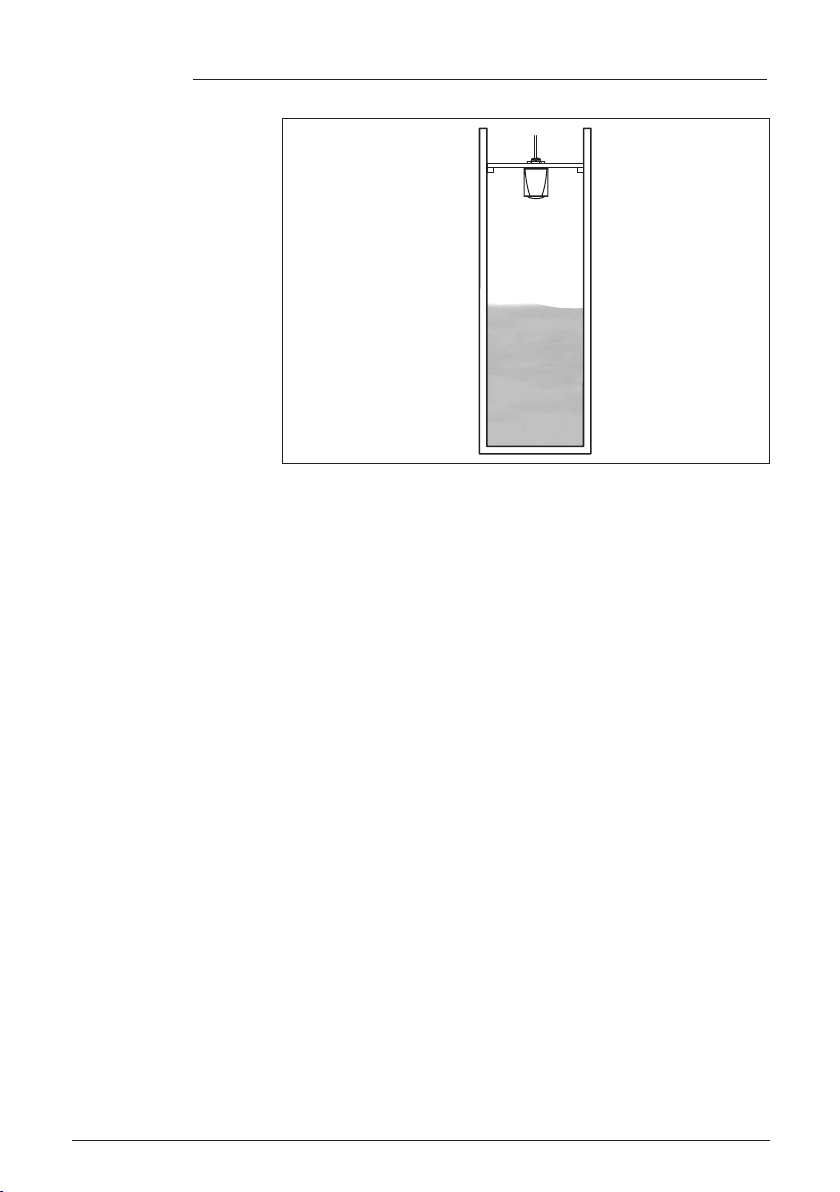

Hydra-Pulse HYC 230 • SDI-12

12

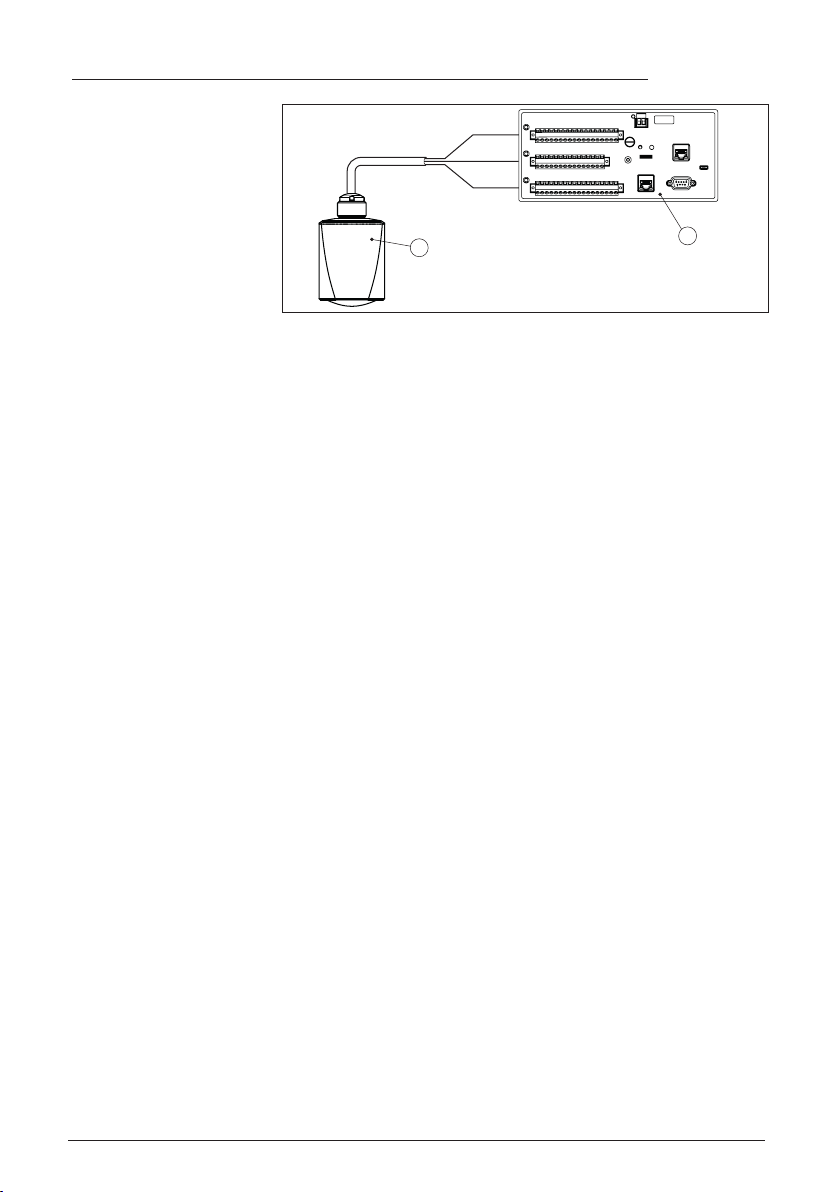

Fig. 4: Connection of Hydra-Pulse HYC 230 SDI-12 to the data logge

1 Sensor

2 Data logger

Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

The packaging consists of environment-friendly, recyclable card-

board. For special versions, PE foam or PE foil is also used. Dispose

of the packaging material via specialised recycling companies.

Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or con-

cealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

•Not in the open

•Dry and dust free

•Not exposed to corrosive media

•Protected against solar radiation

•Avoiding mechanical shock and vibration

•Storage and transport temperature see chapter " Supplement -

Technical data - Ambient conditions"

•Relative humidity 20 … 85 %

Accessories

Screwedangesareavailableindierentversionsaccordingtothe

following standards: DIN 2501, EN 1092-1, BS 10, A SME B 16.5,

JIS B 2210-1984, GOST 12821-80.

Packaging

Transport

Transport inspection

Storage

Storage and transport

temperature

Flanges