Configuration and Calibration Guide HD0679 Rev 1.2.0 7

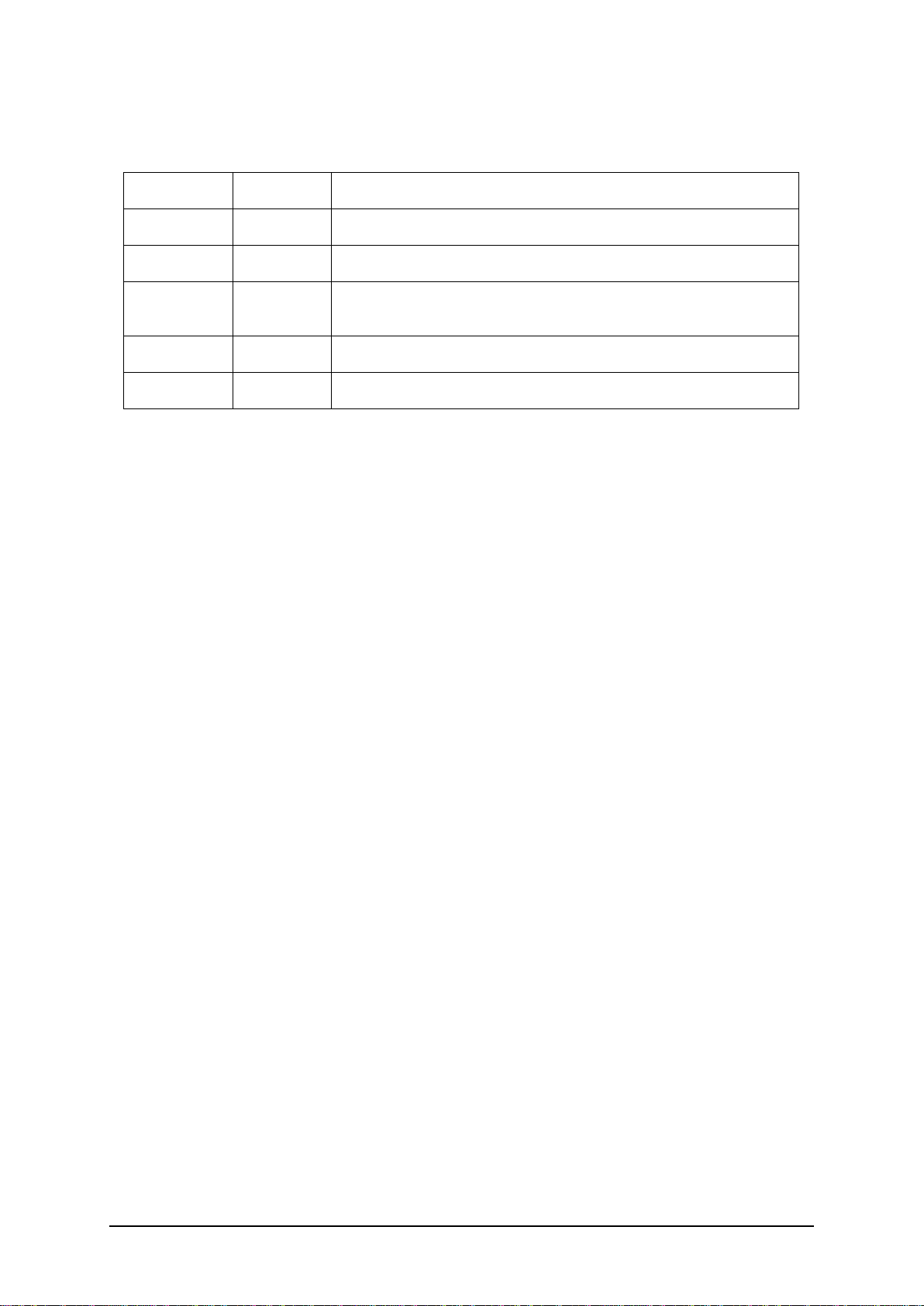

Table of Contents

Chapter 1 Introduction...........................................................................................................................11

1Introduction.................................................................................................................................11

Chapter 2 Configuration........................................................................................................................15

1Configuring the Sensor...............................................................................................................15

2Analogue Output Setup..............................................................................................................15

3Digital Inputs/Output Setup ........................................................................................................17

4Averaging Parameters................................................................................................................19

5Filtering.......................................................................................................................................20

6Typical Moisture Trace from a Hydronix Moisture Sensor in Flowing Material..........................21

7Filtering the Signal When Used in a Mixer Application..............................................................22

9Outputting the Sensor Data........................................................................................................26

Chapter 3 Sensor Integration and Material Calibration.........................................................................29

1Sensor Integration......................................................................................................................29

2Introduction to Material Calibration ............................................................................................29

3SSD Coefficient and SSD Moisture Content..............................................................................31

4Storing Calibration Data.............................................................................................................31

5Calibration Procedure for Flowing Material (Linear) ..................................................................32

6Good/Bad Calibration.................................................................................................................34

7Quadratic Calibration..................................................................................................................35

8Calibrating a sensor in a mixer...................................................................................................36

9Brix Calibration...........................................................................................................................38

Chapter 4 Best Practices ......................................................................................................................41

1General to all Applications .........................................................................................................41

Chapter 5 Sensor Diagnostics ..............................................................................................................43

1Sensor Diagnostics ....................................................................................................................43

Chapter 6 Frequently Asked Questions................................................................................................49

Appendix A Document Cross Reference..............................................................................................51

1Document Cross Reference.......................................................................................................51