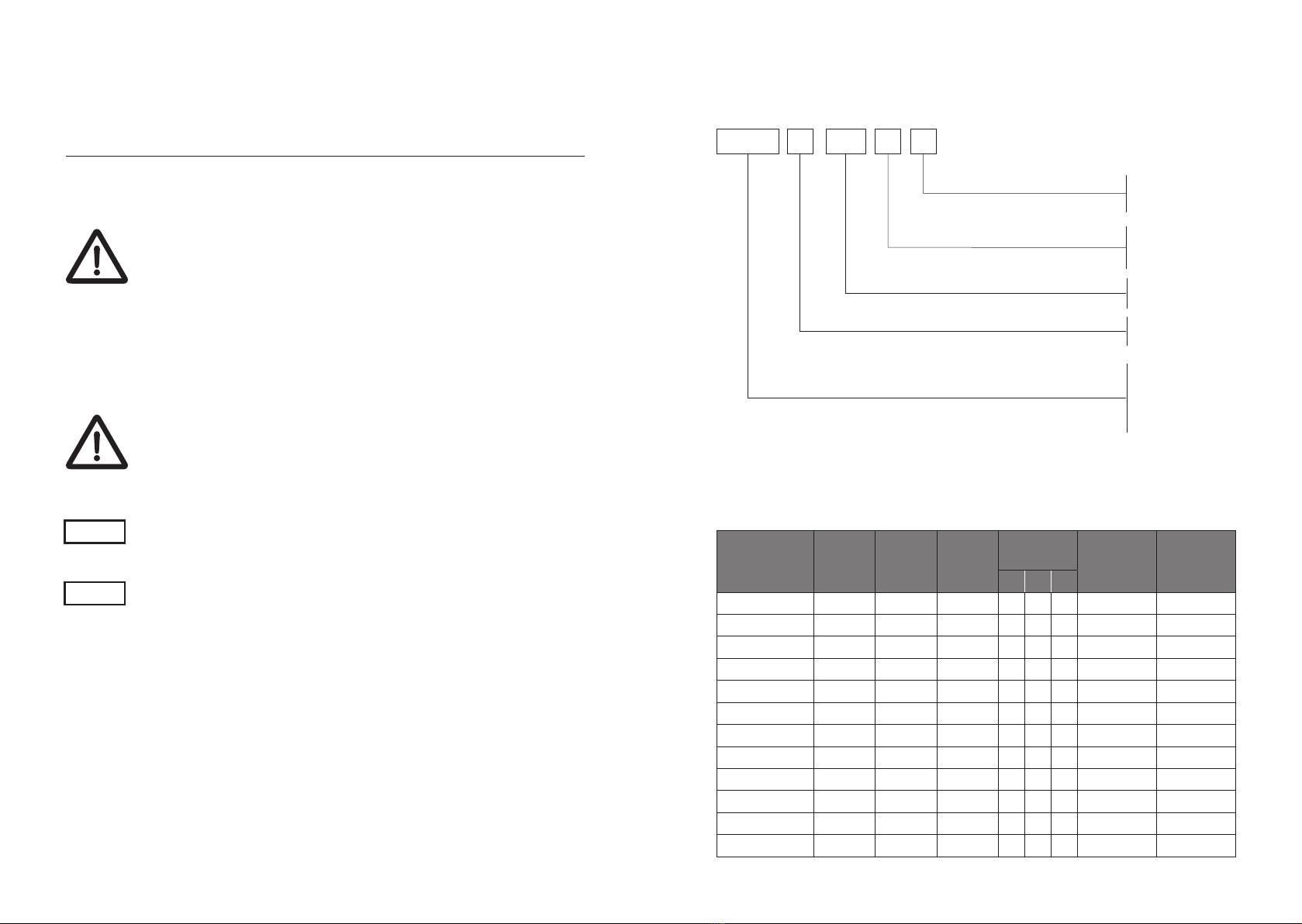

8 9

VI. INSTALLATION

Do not install the pump hanging from the electric cable or the

discharge pipe. Do not lower or lift the pump by means of the

electric cable. Lift the pump using the pipe/hose or a rope

secured to the pump handle.

VII. HOW TO CHECK THE DIRECTION Of ROTATION

If the pump is connected to a piping system, carry out the check of direction of rotation

in this way:

1. Start the pump and check the quantity of water.

2. Stop the pump and interchace two phases in the mains connection.

3. Start the pump and check the quantity of water.

4. Stop the pump.

5. Compare the results taken under points 1 and 3. The largest quantity of water

indicates the correct direction of rotation.

VIII. OPERATION

The pump will start and stop automatically, depending on the liquid level and the cable

lenght of the float switch.

Forced operation

If the pump is used for draining liquid below the stop level of the float switch, the float

switch can be held in a higher position by fastening it to the pump discharge pipe.

During forced operation, the liquid level should be checked regularly to avoid dry

running.

IX. PUMP OPERATION

· The pump shall be submerged 2/3 for long time operation.

· The submerged depth shall be less tahn 5 min.

· The lead cable of single phase pump is three-core rubber covered cables, one of

them yelow-green cable is grounding cable, for safety, the grouding cable shall be

connected safely. At the same time, MUST NOT connect the tree-core cables to

THREE phase power supply.

· When running, if the pump suddenly stopped, or pumped water reduced, or ther is

a noise, must shut off immediately, stop the pump, check the pump, find the reason,

after trouble solved, then switch on to use.

· Because the thermal protection is built-in the pump, when running, if the pump

stopped suddenly after running again, if most part of the pump is running on the wate,

the pump was overload or pump temperature is high, the thermal protection will take

action, it will shut off the power supply, no need to worry, after some time, when the

motor temperature decrease, the thermal protection will be reset automatically, will

continue to run the pump, it is normal. If there is other trouble, or the pump start-stop,

start-stop repeatedly, shall shut off the power supply, check the trouble reason, after

trouble solved, then run the pump.

X. MAINTENANCE

· When the pump will be not used for long time, the pump shall not be submerged in

water for long time, it shall be lifted, clean it, paint with rust prevention oil. Put it in the

well ventilated and dry room.

· Must check pump power cables usually, check if cracking, if cracking, need to

replace it immediately.

· The two faces mechanical seal, after ran 500 hours, need to replace the oil in the oil

chamber with 10# machine oil.

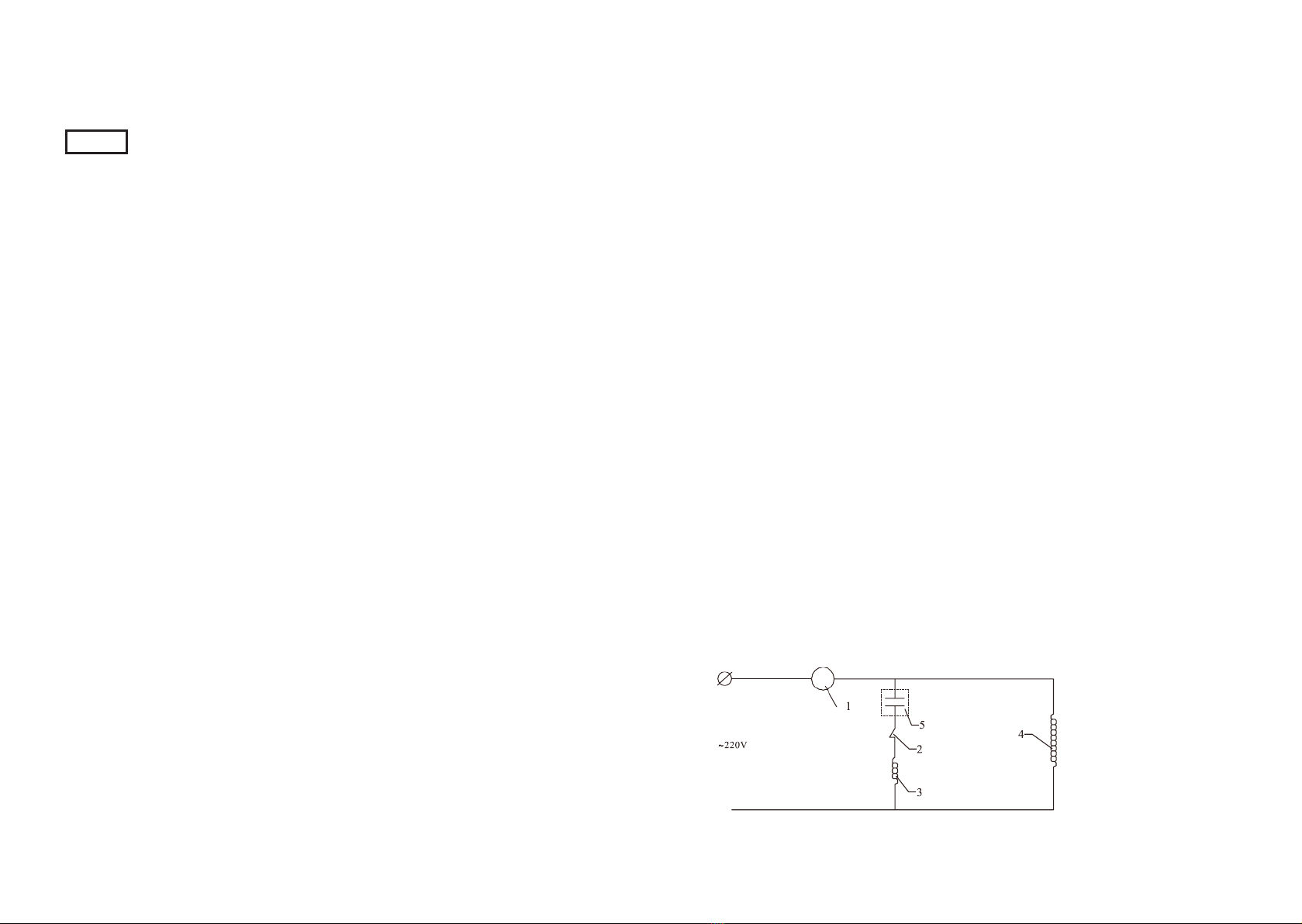

· When repair pump or replace parts, connect as below, must not connect wrongly.

NOTE

1. Thermal protector

2. Centrifugal switch

3. Secondary winding

4. Main winding

5. Capacity (running the pump)